What is the air compressor industry 4.0?

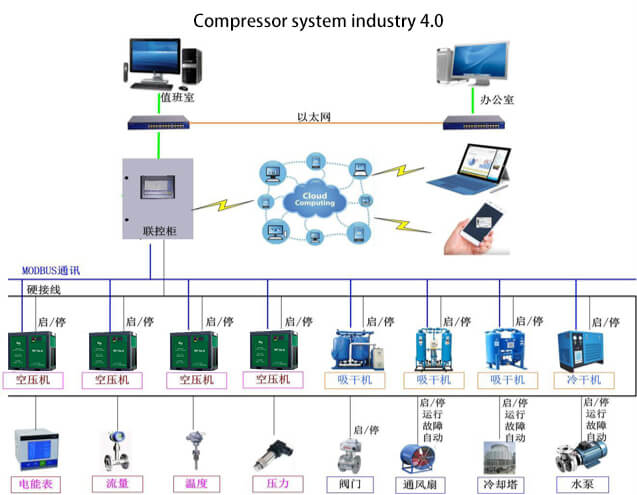

It is connected to the air compressor controller through the adapter (data collector). After obtaining the data in the controller, it can be uploaded to the Internet platform through the flow card, WIFI, etc., and the user can view the running status of the device in real time on the mobile phone and the computer. A system for understanding historical data, fault information, and remote control equipment.

At the same time, relying on the powerful acquisition capability of the adapter, we can also collect data from the equipment (flow meter, frequency converter, point meter, dryer, etc.) of the air compressor station to realize the monitoring and management of the air compressor station.