Introduction: Traditional vs. Energy-Efficient Air Compressors

Traditional compressors suffer from pressure swings, while VSD compressors use PID control for stable operation, saving 7% energy per 0.1MPa reduction.

This article compares design principles, energy-saving technologies, and real-world case studies to demonstrate the advantages of modern oil-injected screw compressors over conventional models.

1. Key Differences: Traditional vs. Energy-Efficient Air Compressors

| Feature | Traditional Fixed-Speed Compressor | Energy-Efficient Oil-Injected Screw Compressor |

|---|---|---|

| Operation | Constant speed, frequent starts/stops | Variable speed drive (VSD), on-demand air supply |

| Efficiency | Low (high specific power input) | High (IE4 motor + two-stage compression) |

| Pressure Control | High pressure fluctuations, “unloading” losses | Constant pressure (±0.01MPa), no wasted energy |

| Idle Power | Consumes 40%-50% of full-load power | Near-zero idle consumption with VSD |

| Maintenance | High wear, frequent servicing | Smart controls extend component lifespan |

2. How Oil-Injected Screw Compressors Save Energy

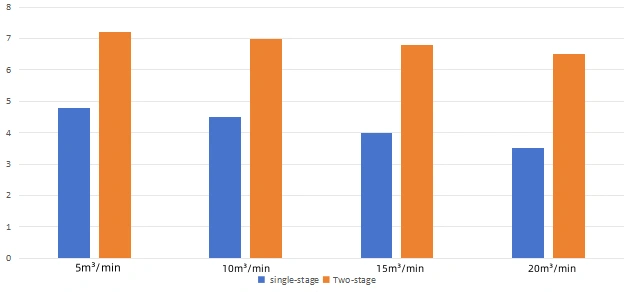

(1) Two-Stage Compression Technology

Traditional single-stage compressors lose efficiency at high pressure ratios. Two-stage compression uses dual rotors to reduce compression ratio per stage, minimizing internal leakage and heat loss.

✅ Energy Savings: 12%-17% higher efficiency vs. single-stage compression.

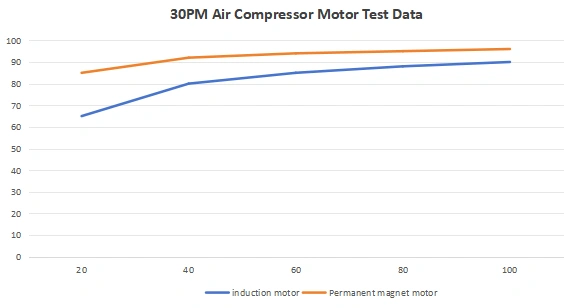

(2) Permanent Magnet Motor (IE4/IE5)

Standard induction motors are only 87%-89% efficient, while permanent magnet (PM) motors reach 94%-97% efficiency with adjustable speed to match demand.

✅ Energy Savings: 20%-30% lower power consumption, especially at partial loads.

(3) Intelligent Pressure Control

Traditional compressors cycle between “load” and “unload,” causing pressure swings. VSD compressors use PID control to maintain stable pressure (±0.01MPa), eliminating over-compression.

✅ Energy Savings: Every 0.1MPa pressure reduction saves 7% in energy.

| Pressure Control Method | Pressure Fluctuation Range (MPa) | Energy Consumption (Relative Value) | Energy Savings Ratio |

| Traditional compressors | ±0.2 | 100% | 0% |

| VSD | ±0.01 | 93% | 7% |

(4) Advanced Cooling & Heat Recovery

Traditional compressors suffer from overheating, reducing performance. Energy-efficient models use oversized coolers + VSD fans to maintain optimal oil temperature (80-85°C), with optional heat recovery for heating/water.

✅ Energy Savings: Heat recovery systems reclaim 60% of waste heat.

3. Case Studies: Proven Energy Savings

Case 1: Cement Plant 132kW Compressor Upgrade

| Metric | Traditional Fixed-Speed | Seize PM VSD Two-Stage | Savings |

|---|---|---|---|

| Annual Power Use | 1,166,000 kWh | 820,000 kWh | 346,000 kWh/year |

| Electricity Cost (¥0.65/kWh) | ¥758,000 | ¥533,000 | ¥225,000/year |

| Payback Period | — | 14 months | — |

✅ Energy Reduction: 29.6%

Case 2: Textile Factory 75kW Compressor Retrofit

| Metric | Traditional VSD | Seize Two-Stage PM | Savings |

|---|---|---|---|

| Load Factor | 70% | 95% | Reduced idle losses |

| Annual Cost | ¥480,000 | ¥340,000 | ¥140,000/year |

| Noise Level | 78 dB | 72 dB | Quieter operation |

✅ Energy Reduction: 25%

Conclusion: Lower Operating Costs with Energy-Efficient Compressors

Modern oil-injected screw compressors deliver 20%-40% energy savings through two-stage compression, PM motors, smart controls, and heat recovery, with payback typically within 1-2 years. For energy-intensive industries, upgrading to efficient compressors is both an environmental and economic imperative.

🔧 Need a customized solution? Contact Seize Air experts for a free energy audit!