When it comes to choosing an air compressor, businesses are increasingly focused on performance, reliability, and cost efficiency. One of the most advanced options is the permanent magnet variable frequency screw compressor (PM VSD compressor), which is designed for energy savings and long-term ROI.

Before you make a purchase, here are ten key questions to consider.

1. How Much Energy Can a PM VSD Compressor Save Compared to a Standard Screw Compressor?

Permanent magnet motors operate with higher efficiency and, when combined with variable frequency drives (VFDs), adjust motor speed to match air demand. This often translates into 30–50% energy savings compared to fixed-speed compressors.

2. What Impact Does Energy Savings Have on ROI?

Since electricity costs account for up to 70% of an air compressor’s lifecycle expenses, reducing energy consumption directly accelerates ROI. Many businesses see payback periods of less than two years.

3. Does the Compressor Operate Efficiently at Partial Loads?

Air demand in most factories fluctuates. Traditional compressors waste energy during low demand, but PM VSD compressors automatically adapt, ensuring consistent efficiency across different load conditions.

4. How Reliable is the Permanent Magnet Motor Design?

Unlike traditional motors, permanent magnet motors eliminate slip losses and reduce heat generation. This enhances durability and ensures stable, long-term performance.

5. Can the System Reduce Maintenance Costs?

By minimizing stress on components and running more smoothly, PM VSD compressors generally require fewer maintenance interventions compared to conventional models, further contributing to cost savings.

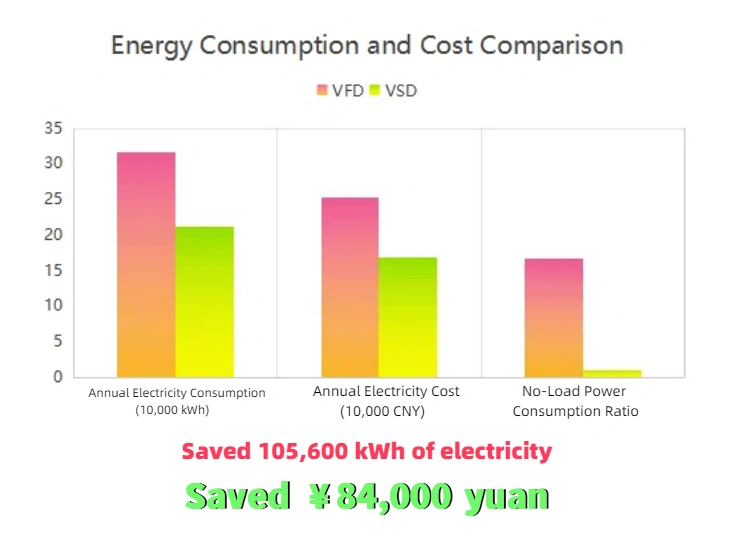

6. What Are the Long-Term Energy and Cost Projections?

Before purchasing, it’s crucial to calculate projected savings. For instance, switching to a PM VSD compressor can save tens of thousands of dollars annually depending on operating hours, electricity rates, and production needs.

7. How Quiet and Environmentally Friendly Is It?

The optimized motor design reduces vibration and noise levels, creating a quieter workplace. Lower energy consumption also translates into a smaller carbon footprint.

8. Is the Technology Proven in Industrial Applications?

PM VSD compressors are widely used in industries such as electronics, automotive, pharmaceuticals, and food processing. Their reliability in demanding environments demonstrates proven results.

ALT text: Industry icons showing applications of PM VSD air compressors in automotive, electronics, and food industries

9. Does It Offer Intelligent Control Features?

Advanced PM VSD systems often integrate smart controls, allowing for real-time monitoring, predictive maintenance alerts, and optimized performance based on factory demand.

10. Which Supplier Provides the Best Value for Long-Term Operations?

Beyond the machine itself, selecting the right supplier ensures proper installation, after-sales support, and access to original spare parts—critical factors for maximizing ROI.

Conclusion

Asking the right questions before buying an air compressor can make a significant difference in both operational efficiency and long-term cost savings. A permanent magnet variable frequency screw compressor not only lowers energy bills but also delivers sustainability benefits, reduced maintenance, and a faster payback period.

About Seize Air

At Seize Air, we specialize in advanced air compression solutions designed for global industries. Our permanent magnet variable frequency screw compressors are engineered to deliver maximum energy efficiency, reliability, and long-term ROI. Whether you are looking to upgrade your existing system or explore new solutions, Seize Air offers technology that supports your productivity and sustainability goals.