Introduction

In the highly regulated pharmaceutical sector, even the slightest trace of oil or other contaminants in compressed air can compromise product safety and compliance. For this reason, choosing the right air compressor for operations in the pharmaceutical industry is not just a matter of selecting the right equipment — it is also a necessity for ensuring quality and compliance. Fortunately, modern advancements in oil-free screw compressor technology now provide reliable, energy-efficient solutions that protect product purity and production efficiency.

The Unique Demands of the Pharmaceutical Industry

The production of pharmaceuticals requires compressed air that meets strict international standards, such as ISO 8573-1 Class 0, GMP and FDA regulations. These standards guarantee that the air used in clean rooms, packaging lines and medical production environments is entirely free from oil and other contaminants.

In addition to purity, facilities also demand:

- Stable pressure control for continuous production lines;

- Low discharge temperatures to protect equipment from thermal stress.

- They also demand energy-efficient performance to reduce long-term operating costs.

Oil-Free Screw Air Compressors: A Safer Alternative

Traditional lubricated compressors pose a risk of oil carryover, which can contaminate medicines or packaging. In contrast, an oil-free screw air compressor designed for use in the pharmaceutical industry eliminates this risk entirely.

Key benefits include:

- Zero oil contamination, thanks to advanced sealing and isolated lubrication systems.

- Longer maintenance intervals, reducing downtime for busy production schedules.

- Reduced operating costs thanks to the elimination of the need for oil filters and changes.

This technology ensures compressed air purity and aligns with the sustainability and compliance goals of pharmaceutical companies.

Three-Stage Compression for Maximum Efficiency

Many pharmaceutical facilities operate under high air demand and over extended shifts. A modern three-stage compression design offers several key advantages:

- Lower discharge temperature (around 110°C compared to 200°C+ in two-stage systems), which extends component life;

- It is also more energy efficient, with up to 15% lower power consumption compared to conventional designs.

- It also has a wider operating pressure range (0.8–2.5 MPa), making it suitable for diverse applications, from tablet coating to sterile packaging.

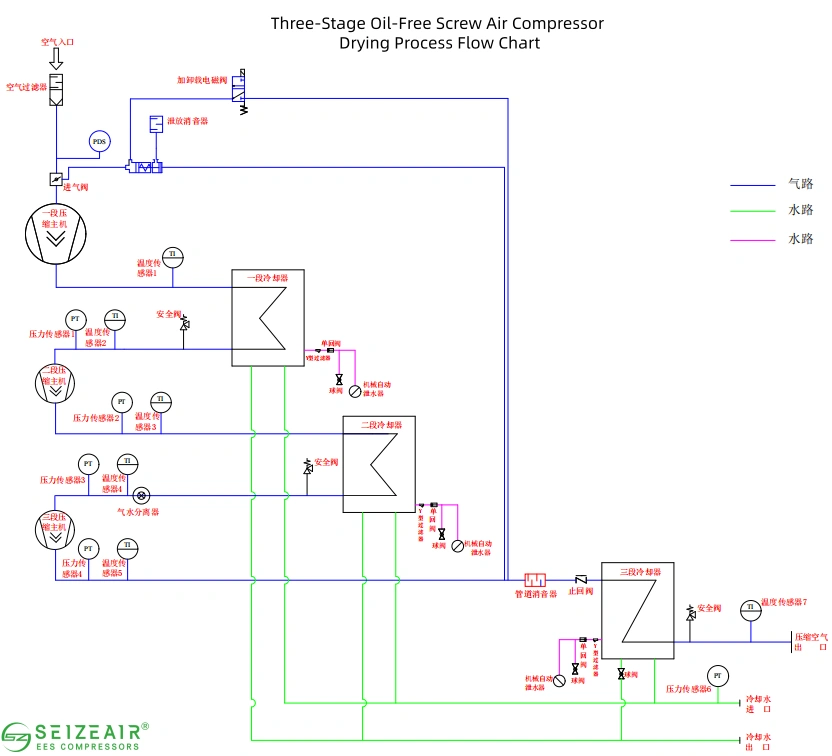

After the air filter removes the dust, the air enters the first-stage compressor via the intake valve, where it is compressed. The compressed gas then passes through the first-stage cooler before entering the second-stage compressor for further compression. After this, the gas enters the second-stage cooler and then passes through the gas-liquid separator into the third-stage compressor for further compression. After passing through the pipeline muffler to reduce noise, the gas flows through the check valve into the third-stage cooler to cool down before being delivered to the usage system.

Energy Efficiency for Cleanroom Production

Pharmaceutical cleanrooms require a lot of energy to maintain sterile conditions. Using an energy-efficient air compressor for cleanroom production can help to reduce energy bills and environmental impact.

Advanced models incorporate:

- Permanent magnet motors with up to 94% efficiency;

- variable speed control to adapt to fluctuating air demand;

- smart monitoring systems that provide real-time data on energy usage, pressure and performance.

These features reduce energy consumption and support pharmaceutical companies’ sustainability initiatives.

Pharmaceutical Grade Compressed Air Solutions

Not only is compressed air used to power equipment, it also comes into direct contact with products in many pharmaceutical processes. Applications include:

- supplying sterile air in vaccine production;

- Air-driven controls in tablet and capsule manufacturing;

- Packaging and labelling operations requiring precise pneumatic control.

In these scenarios, only compressed air solutions of pharmaceutical grade that guarantee purity and reliability can be trusted. Oil-free screw compressors deliver exactly that, ensuring compliance and protecting patient safety.

Conclusion

When it comes to compressed air quality, the pharmaceutical industry cannot afford risks. Selecting the appropriate air compressor for pharmaceutical operations ensures compliance with international standards, enhances efficiency and protects product integrity.

Seize Air, a leading Chinese manufacturer of advanced air compressors, offers reliable, energy-efficient, oil-free screw air compressors that are specifically designed for demanding applications such as those in the pharmaceutical industry. By combining three-stage compression, Class 0 oil-free certification and smart energy-saving features, Seize Air provides pharmaceutical companies worldwide with a future-ready solution.