Introduction

In today’s highly competitive manufacturing landscape, industrial air compressors are essential for powering tools, automating processes and ensuring efficiency across production lines. From automotive assembly to food packaging, compressed air has become the ‘fourth utility’ of modern factories, alongside electricity, water and gas. Amidst rising energy costs and mounting environmental concerns, the demand for energy-efficient industrial air compressors in manufacturing plants is greater than ever.

The Backbone of Modern Manufacturing

Industrial air compressors are indispensable in countless manufacturing operations. They supply clean, pressurised air to power pneumatic tools, control robotic arms and drive essential machinery. Without a reliable supply of compressed air, production could be subject to costly downtime and inconsistent product quality.

Air compressors are used for different purposes in different industries:

- Automotive manufacturing: Powering paint sprayers, tightening tools, and robotic systems.

- Electronics industry: Maintaining dust-free environments with precision air control.

- Food and beverage sector: Ideal for packaging, bottling, and maintaining hygienic production lines.

- Pharmaceutical production: Ensuring clean, oil-free compressed air for sensitive processes.

As the importance of automation and precision increases, factories are relying on compressors not only as energy sources, but also as integral components of productivity and quality assurance.

Energy Efficiency and Cost Savings

One of the most significant shifts in manufacturing is the increased focus on sustainability and operational efficiency. Energy-efficient industrial air compressors are designed for use in manufacturing plants and are intended to minimise power consumption while maintaining stable air output.

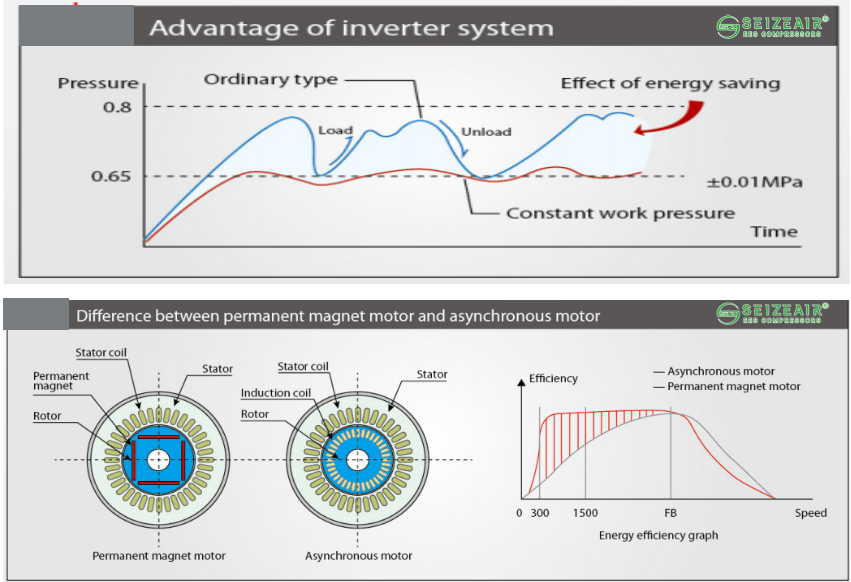

In contrast, traditional fixed-speed compressors often consume more energy than is necessary. In contrast, variable speed drive (VSD) compressors automatically adjust motor speed based on air demand, reducing energy usage by up to 35%. Furthermore, heat recovery systems can convert waste heat into usable energy for space heating or process applications, thereby enhancing plant efficiency even further.

Other benefits of energy-efficient compressors include:

- Reduce your carbon footprint and ensure compliance with environmental regulations.

- Lower operating costs thanks to optimised energy usage.

- Equipment lifespan is extended due to reduced strain on components.

When selecting an industrial air compressor for continuous, heavy-duty use, decision-makers should prioritise systems offering intelligent control, robust filtration and advanced monitoring capabilities, in order to ensure long-term reliability and efficiency.

Reliability and Performance for Heavy-Duty Operations

Manufacturing facilities often operate around the clock, so they require equipment that can perform continuously under demanding conditions. The best industrial air compressor for heavy-duty, continuous use must combine durability with consistent performance.

The key factors that ensure reliability are:

- High-quality components: -precision-engineered rotors;durable bearings.

- Effective cooling systems: These prevent overheating and maintain stable air delivery.

- Advanced monitoring systems: For early fault detection and maintenance scheduling.

Oil-free screw compressors are particularly well-suited to industries requiring contamination-free air. They eliminate the risk of oil residue, ensuring a clean and safe air supply for sensitive applications such as pharmaceuticals, electronics and food packaging.

Integration with Smart Manufacturing

The advent of Industry 4.0 has transformed the way manufacturers operate. Today’s industrial air compressors can be seamlessly integrated with smart factory systems, enabling real-time data collection, predictive maintenance and remote performance monitoring.

Factory managers can use performance metrics such as pressure fluctuations, temperature and energy consumption to make data-driven decisions that enhance productivity and reduce downtime. Smart compressors improve operational reliability and align with sustainability goals by reducing waste and optimising resource usage.

Conclusion

As manufacturing continues to evolve, the role of industrial air compressors becomes increasingly vital. From powering essential equipment to supporting smart, sustainable production systems, these machines are the backbone of industrial efficiency.

Factories seeking reliable, durable and energy-efficient solutions should consider Seize Air‘s comprehensive range of oil-free screw air compressors, which are engineered for superior performance and long-term value. As a leading Chinese manufacturer, Seize Air is dedicated to delivering cutting-edge compressed air solutions that enhance productivity and sustainability in manufacturing industries worldwide.