Introduction

In the underground mining industry, compressed air is one of the most essential energy sources. From drilling and blasting to ventilation and pneumatic tool operation, an air compressor for mining is the core equipment that keeps production running efficiently and safely.

Compared with surface applications, underground mining environments are more demanding — characterized by high humidity, dust, and limited ventilation. Therefore, choosing a reliable and energy-efficient mining air compressor is critical for maintaining productivity, safety, and cost control.

This article explains how to select the best air compressor for underground mining, based on performance, type, operating conditions, and long-term efficiency.

The Role of Air Compressors in Mining

An air compressor is far more than a power source; it is the “energy hub” that drives almost every critical mining operation.

Drilling and Blasting

Compressed air powers drilling machines and rock breakers, improving precision and safety during blasting operations.

Ventilation and Dust Control

Air compressors help maintain air circulation and control dust concentration, which is vital for miner health and visibility.

Pneumatic Tools and Equipment

Tools such as jackhammers, riveters, and material movers rely on stable compressed air to operate efficiently.

Cleaning and Material Conveying

Compressed air assists in cleaning mining tunnels and machinery, while also helping with the transport of materials.

Ultimately, a reliable air compressor for mining directly determines the operational stability, safety, and energy efficiency of the entire mine.

Environmental Challenges in Mining

Underground mining presents harsh working conditions that make compressor selection more complex.

High humidity and dust require advanced filtration and anti-corrosion protection. Limited space and poor ventilation demand compact design, efficient cooling, and minimal maintenance downtime.

Because temperature and air pressure fluctuate, an unsuitable air compressor can lead to reduced efficiency, overheating, or frequent breakdowns. Therefore, the best air compressor for mining should offer durability, long service life, and consistent output even in extreme underground environments.

Common Air Compressor Types for Mining

Different compressor technologies provide distinct advantages depending on mining needs.

1. Rotary Screw Air Compressor

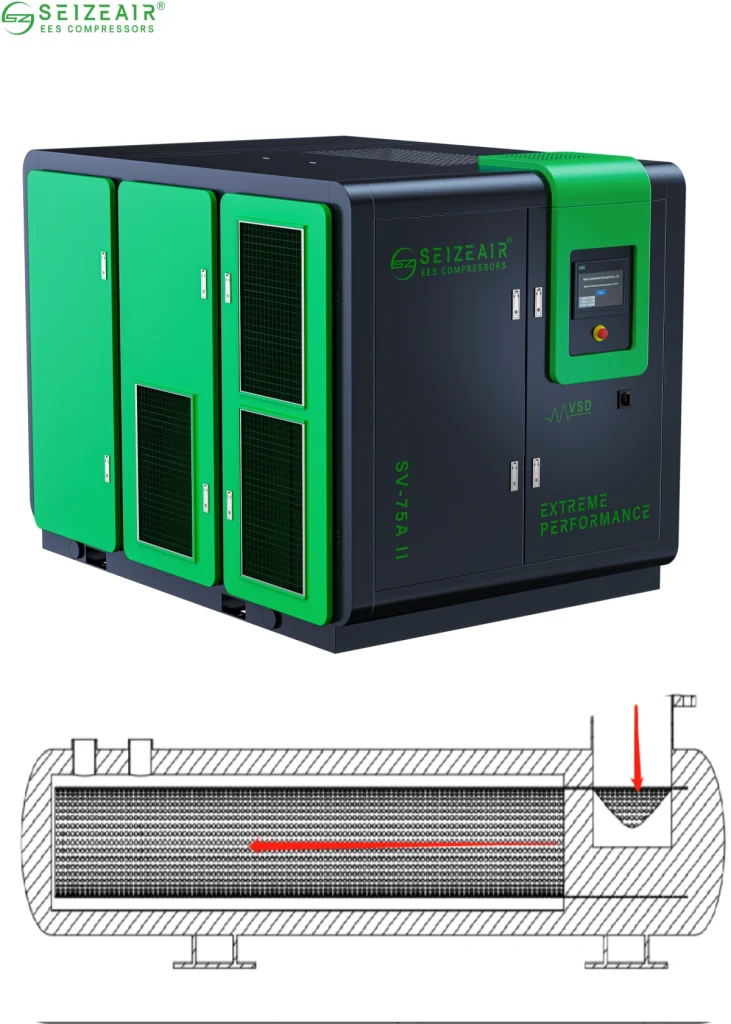

The rotary screw type offers continuous operation and steady airflow, ideal for long shifts in mines. It is energy-efficient, low-noise, and easy to maintain — a leading choice among mining air compressors today.

2. Centrifugal Air Compressor

Centrifugal compressors deliver oil-free, high-volume air suitable for large-scale mining operations or centralized air systems. They are quiet and efficient but require stable installation and clean air conditions.

3. Piston (Reciprocating) Air Compressor

Known for low upfront cost and simple structure, piston compressors suit small mines or temporary sites. However, they generate more noise and vibration and have lower energy efficiency, making them less common in modern underground mining.

When choosing a type, consider mine size, air demand, ventilation conditions, and operating cost.

Key Factors to Consider When Selecting an Air Compressor for Mining

Choosing the right air compressor for underground mining involves multiple technical and operational considerations:

1. Airflow and Pressure Requirements

Different mining activities require varying pressure levels. Drilling and blasting need high pressure and large airflow, while pneumatic tools need steady, moderate air supply. Proper sizing prevents both shortages and waste.

2. Energy Efficiency and Cost

Energy consumption represents a major portion of mining expenses. Variable Speed Drive (VSD) compressors automatically adjust motor power to match air demand, significantly improving energy efficiency.

3. Reliability and Maintenance

Maintenance is difficult underground. Compressors with sealed designs, automatic lubrication, and long service intervals reduce downtime and ensure reliability.

4. Air Quality and Safety Compliance

Compressed air purity is crucial for safety and environmental compliance. Oil-free compressors or units with advanced filtration systems help meet ISO 8573-1 air quality standards.

5. Size and Installation Flexibility

Compact and portable compressors are ideal for narrow tunnels or mobile operations. Modular systems also make expansion and servicing more convenient.

Energy Efficiency and Smart Control Trends

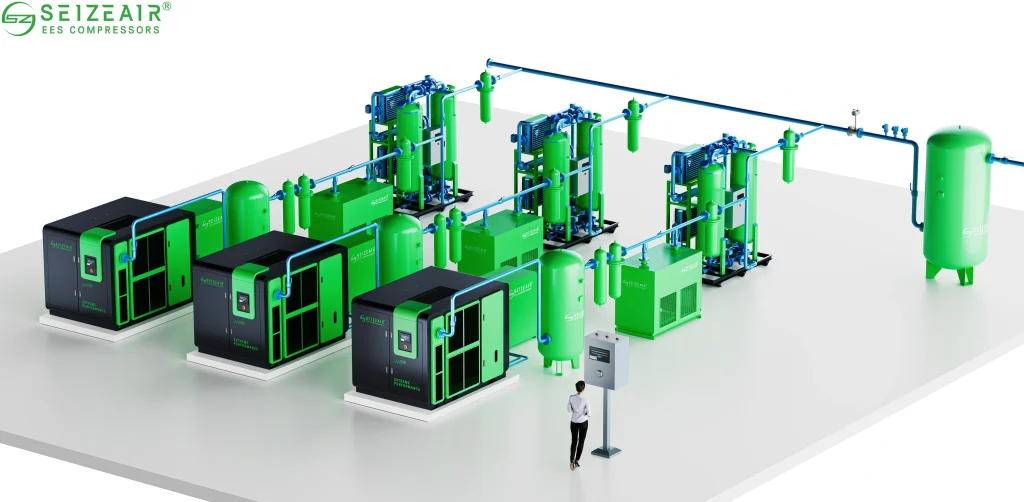

Modern air compressor for mining systems are becoming increasingly intelligent. Through IoT-based monitoring, operators can track performance, energy consumption, and maintenance needs in real time.

Smart controllers automatically balance load distribution between multiple compressors, maximizing efficiency and minimizing idle time. Predictive maintenance systems also reduce the risk of unexpected breakdowns and costly downtime.

This technological shift not only enhances energy efficiency but also increases operational safety and sustainability in mining operations.

Common Mistakes and Optimization Tips

Many mining operators still make avoidable mistakes when purchasing an air compressor for mining:

- Focusing only on initial price: Low-cost units often consume more energy and require frequent maintenance.

- Ignoring environmental factors: Compressors must be designed for humidity, dust, and temperature variations.

- Neglecting maintenance schedules: Poor upkeep leads to reduced efficiency and shorter equipment life.

- Lack of backup systems: If the main compressor fails, production halts — causing major financial losses.

To avoid these pitfalls, conduct proper airflow analysis, choose a trusted manufacturer, establish maintenance routines, and monitor system performance continuously.

Recommended Brands and Solutions

Several global brands have proven expertise in mining air compressor solutions, including Ingersoll Rand, Atlas Copco, Kaeser, and Seize.

Among them, Seize Air Compressor stands out for its advanced variable-speed technology, anti-dust protection, and intelligent monitoring systems. Its modular air compressor for mining solutions are engineered for harsh underground environments, offering high efficiency and reliability.

Seize compressors are widely used in non-coal and metal mines worldwide, recognized for their durability, energy savings, and ease of service.

Conclusion

Selecting the right air compressor for mining is not simply a technical decision — it is a strategic investment that affects safety, productivity, and operational cost.

An ideal underground air compressor should combine energy efficiency, durability, compact design, low maintenance, and clean air output. With proper selection and configuration, mining companies can enhance productivity while reducing long-term costs.

By partnering with trusted manufacturers like Seize, operators gain access to customized, intelligent, and reliable compressed air solutions that meet the unique demands of underground mining.