Introduction

In today’s industrial world, compressed air is often called the “fourth utility,” ranking alongside electricity, water, and natural gas. From automotive and metallurgy to electronics, food processing, and pharmaceuticals, nearly every manufacturing process relies on compressed air to power equipment and drive automation.

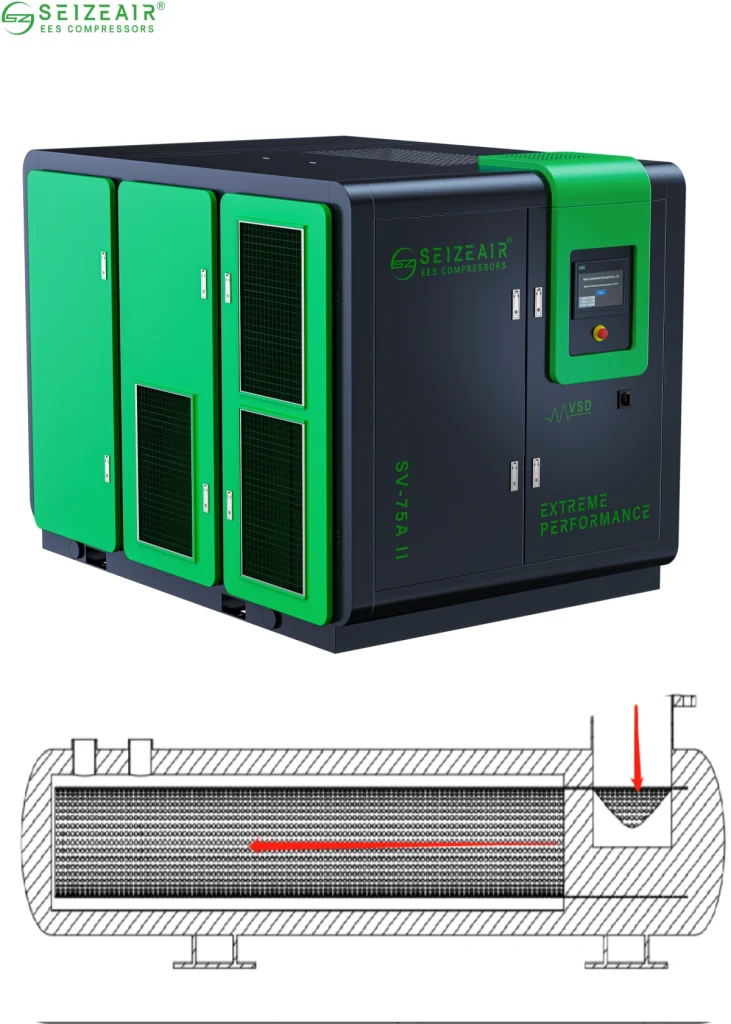

Among all compressor types, the industrial screw compressor stands out for its reliability, energy efficiency, and continuous air delivery. As the heart of any industrial compressed air system, it directly influences plant energy consumption, production stability, and operating costs.

Understanding the Industrial Screw Compressor: Definition and Core Function

An industrial screw compressor is a positive displacement machine that compresses air using two interlocking helical rotors. Unlike piston compressors, which use a reciprocating motion, screw compressors use rotary motion — ensuring smooth, vibration-free, and efficient operation.

These machines are designed for 24/7 operation in demanding environments, featuring high-performance motors, durable materials, and advanced control systems suitable for manufacturing, mining, energy, and construction industries.

Main Components of an Industrial Screw Compressor System

Twin Rotors – The Heart of the Compression Process

At the center of every rotary screw air compressor are two rotors — a male and a female rotor — that trap air and reduce its volume as they rotate. High machining precision minimizes internal leakage and ensures consistent compression efficiency.

Compressor Casing and Compression Chamber

The casing forms the pressure-tight enclosure that allows smooth airflow and optimal sealing. Industrial-grade casings are engineered to withstand high temperatures and pressures, ensuring durability during continuous operation.

Inlet Valve and Discharge Port Design

The inlet valve controls how much air enters the compression chamber, while the discharge port releases the compressed air into the air network. Proper port geometry ensures the built-in pressure ratio matches the system’s working pressure for maximum energy efficiency.

Lubrication and Oil Separation System

Oil-injected models use lubricating oil to reduce friction, cool the compression chamber, and seal rotor gaps. The air-oil mixture is later filtered through an oil separator, ensuring clean output air and oil recovery.

Oil-free designs, however, rely on timing gears and precision clearances — ideal for industries requiring contamination-free air.

Cooling System for Industrial Screw Compressors

Heat management is vital. Air or water cooling systems, along with oil and aftercoolers, maintain optimal operating temperatures, protecting internal components from thermal stress and ensuring stable performance.

Smart Control System and Monitoring Sensors

Modern industrial air compressors are equipped with intelligent control units that monitor parameters like temperature, pressure, and power usage. Integrated Variable Speed Drives (VSD) automatically adjust output based on demand, improving energy efficiency and extending equipment lifespan.

How an Industrial Screw Compressor Works

Suction Phase – Air Intake and Chamber Filling

Ambient air enters the compression chamber through the inlet valve. The rotors rotate, trapping the air in tightly sealed cavities. Efficient suction depends on quick valve response and smooth airflow.

Compression Phase – Pressure Build-Up and Energy Conversion

As the rotors turn, the trapped air moves along their length, with chamber volume decreasing and pressure increasing. The compressor’s built-in pressure ratio — determined by rotor geometry — must match the system’s operating pressure to avoid energy losses from under- or over-compression.

Discharge Phase – Air Delivery and Oil Separation

When the compressed air reaches the discharge port, it is released into the air network or storage tank. Oil-injected systems separate the oil before discharge, while oil-free units rely on multi-stage compression and intercooling for higher pressures and air purity.

Continuous Operation and Efficiency Optimization

The key advantage of an industrial rotary screw air compressor is continuous, pulse-free airflow. Combined with VSD technology, it allows for 35%–60% energy savings, adapting seamlessly to variable air demand in industrial environments.

Types of Industrial Screw Compressors and Their Applications

Oil-Injected Industrial Screw Compressor

These models inject oil during compression for cooling, lubrication, and sealing.

- Advantages: Cost-effective, durable, and capable of high load operation.

- Limitations: Output air may contain oil traces, requiring additional filtration.

- Applications: Metal processing, heavy manufacturing, and construction.

Oil-Free Industrial Screw Compressor

Oil-free designs prevent any oil from entering the compression chamber, making them ideal for clean industries.

- Advantages: Delivers contamination-free air, ISO 8573-1 Class 0 certified.

- Limitations: Higher initial cost and maintenance complexity.

- Applications: Electronics, pharmaceuticals, food and beverage, and biotechnology.

Fixed-Speed vs Variable Speed Drive (VSD) Screw Compressors

Fixed-speed compressors run continuously, leading to wasted energy under low demand.

VSD industrial screw compressors automatically adjust motor speed based on real-time usage, achieving up to 60% energy savings — essential for modern, energy-efficient factories.

Industrial Applications of Screw Air Compressors

The industrial screw compressor plays a crucial role across multiple industries:

- Manufacturing: Provides stable compressed air for assembly lines, pneumatic tools, and painting systems.

- Automotive & Electronics: Powers robotics, welding, and precision production lines.

- Food & Pharmaceuticals: Supplies clean, oil-free air for hygienic and safe processing.

- Mining & Construction: Supports drilling, conveying, and ventilation systems.

- Energy & Chemicals: Stabilizes pressure in control valves and instrumentation.

Why Choose an Industrial Screw Compressor?

- Continuous Air Supply: Designed for uninterrupted 24/7 operation.

- Superior Energy Efficiency: Rotary screw design minimizes friction and energy loss.

- Compact Design and Easy Maintenance: Fewer moving parts reduce downtime.

- Low Noise and Vibration: Smooth rotation ensures quieter, more stable operation.

- Long-Term Reliability: Precision engineering ensures years of consistent performance.

Maintenance and Energy Optimization for Industrial Screw Compressors

- Regular Preventive Maintenance: Replace filters, inspect oil, and clean coolers regularly to maintain system efficiency.

- Eliminate Air Leaks: Up to 20% of compressed air energy is lost through leaks — regular inspections save significant costs.

- Optimize Working Pressure: Adjust pressure settings to match production needs and avoid unnecessary power consumption.

- Adopt Variable Speed Control (VSD): Automatically adapts to air demand, lowering energy costs and mechanical wear.

- Use Smart Monitoring Systems: IoT-based analytics provide real-time performance tracking and predictive maintenance alerts.

Conclusion

The industrial screw compressor is an indispensable part of modern industry — combining energy efficiency, reliability, and long service life. It powers production lines, supports automation, and drives sustainable growth by reducing energy consumption.

When selecting a compressor, companies should consider their specific air quality needs, operating pressure, duty cycles, and energy goals.

With proper configuration and maintenance, an industrial screw compressor becomes a lasting investment in operational excellence.

For organizations striving for higher performance and energy savings, Seize Industrial Screw Compressors represent a trusted solution — driving smart manufacturing and sustainable production worldwide.