What is a Centrifugal Air Compressor?

In industrial air supply systems, selecting the appropriate equipment type is often the first step. A centrifugal air compressor is a device that uses a high-speed rotating impeller to draw air (or gas) into its center, accelerate it outward, and then convert kinetic energy into pressure energy within a diffuser or guide vane structure. The basic process is: Air enters the impeller center → Impeller rotation flings air outward, increasing kinetic energy → Kinetic energy decelerates in the diffuser while pressure rises → Discharged into the system

This type of compressor belongs to “dynamic compressors,” distinct from “positive displacement compressors” like screw or reciprocating types.

Due to its structural characteristics, the centrifugal air compressor offers significant advantages in scenarios requiring high flow rates, continuous operation, and high efficiency.

Introduction to Screw Air Compressors

Compared to centrifugal compressors, screw air compressors utilize two intermeshing screw rotors. After intake, gas compression occurs through the reduction of volume between the rotors, thereby pressurizing the air.

Screw compressors typically feature compact designs and flexible startup capabilities, making them suitable for applications involving small to medium air volumes, variable loads, and frequent start-stop cycles. While their initial investment may be lower than large centrifugal units, their long-term operational efficiency or maintenance requirements may be slightly inferior under certain operating conditions.

Therefore, understanding the differences and application scenarios between centrifugal and screw compressors is crucial when selecting between them.

Key Differences Between Centrifugal and Screw Compressors

Centrifugal air compressors accelerate airflow through high-speed impellers, converting kinetic energy into static pressure energy.

Screw compressors are positive displacement compressors that reduce gas volume through intermeshing rotors to achieve compression. Thus, the former operates on “high-speed kinetic energy conversion,” while the latter relies on “volume sealing.”

Differences in Flow Rate and Capacity Range

For high-flow, continuous operation scenarios, centrifugal air compressors excel, delivering greater air volume and more stable output.

Screw compressors, however, offer greater flexibility in small-to-medium-scale systems with fluctuating loads.

Energy Efficiency and Operating Costs

In full-load, high-flow operation, centrifugal compressors typically achieve superior efficiency. For instance, data indicates centrifugal compressors demonstrate outstanding energy savings under heavy loads.

However, screw compressors may perform better under fluctuating or partial load conditions due to their superior adaptability to variable demands.

Overall, while centrifugal compressors involve higher initial investment and more complex design, they can achieve lower long-term energy consumption and maintenance requirements in suitable applications.

Maintenance and Reliability

Centrifugal compressors feature fewer contact components and lower wear, ensuring high reliability during sustained heavy-duty operation.

Screw compressors require relatively simple maintenance, but factors like lubrication systems and rotor meshing can lead to higher maintenance costs under frequent start-stop cycles or harsh operating conditions.

From a long-term perspective, selecting a centrifugal air compressor can reduce total cost of ownership for facilities with stable, high-volume air demand.

Application Scenarios for Centrifugal vs. Screw Air Compressors

Centrifugal Air Compressor Applications

Large manufacturing plants, power plants, petrochemical, metallurgical, and steel industries requiring continuous supply of high-volume compressed air.

Applications with long operating hours, stable loads, and high air quality requirements (e.g., oil-water separation, oil-free air).

For instance, some modern centrifugal air compressors achieve oil-free discharge.

Screw Compressor Applications

Centrifugal solutions offer distinct advantages when systems demand high efficiency, low vibration, minimal maintenance, and extended lifespan.

Suitable for small to medium-sized workshops, automated assembly lines, food packaging, maintenance facilities, and similar environments.

Ideal for locations with moderate air volume requirements, frequent load fluctuations, or high start/stop cycles.

Preferred when initial investment budgets are constrained, rapid deployment is needed, or floor space is limited.

For these applications, screw compressors often represent a more cost-effective solution.

How to Choose Between Centrifugal and Screw Compressors?

1. Assess air volume requirements: Centrifugal compressors excel when daily air flow is very high and continuous operation is prolonged.

2. Evaluate load fluctuations: Screw compressors offer greater flexibility for systems with significant load variations, frequent starts/stops, and moderate air demand.

3. Consider energy consumption and lifecycle costs: While screw compressors have lower initial expenses, their long-term energy consumption and maintenance costs may be higher. Centrifugal compressors, though requiring greater upfront investment, offer superior long-term returns.

4. Facility conditions and service infrastructure also matter

Centrifugal compressors are typically large, requiring robust foundations, effective cooling systems, and adequate air intake.

The availability of a comprehensive service network and experienced maintenance personnel is also critical. Inadequate local service infrastructure can significantly amplify repair costs.

5. Consider hybrid or combined solutions

The optimal solution isn’t always a single choice. Many facilities employ a centrifugal air compressor as the primary air source while utilizing screw compressors for backup or fluctuating demand. This “primary + auxiliary” combination is quite common.

Why Centrifugal Air Compressors May Be the Better Choice

Under high-capacity, stable operating conditions, centrifugal compressors deliver exceptional energy efficiency. Numerous technical studies indicate their operational efficiency surpasses that of screw compressors.

Their simpler structure and fewer wear components reduce maintenance frequency and enhance system reliability.

For factories with high demand and extended runtime, centrifugal compressors lower total cost of ownership over long-term operation.

Therefore, when your facility demands substantial air supply, operates under high loads, and seeks to minimize long-term operational costs, selecting a centrifugal air compressor is a prudent decision.

Conclusion

In the “Centrifugal Air Compressor vs Screw Compressor” selection debate, there is no “absolutely better” answer. The key lies in your specific operating conditions, air volume requirements, runtime, load fluctuations, and budget constraints.

If your facility requires extremely high air volume, continuous operation, high efficiency, low maintenance, and has sufficient budget and space, then a centrifugal air compressor is likely the superior choice.

If your demand is moderate, load fluctuations are significant, budget is constrained, or space is limited, then a screw compressor may be more practical.

Crucially: Understanding the differences between the two in terms of operating principles, efficiency, cost, and suitable applications is essential for making an informed decision.

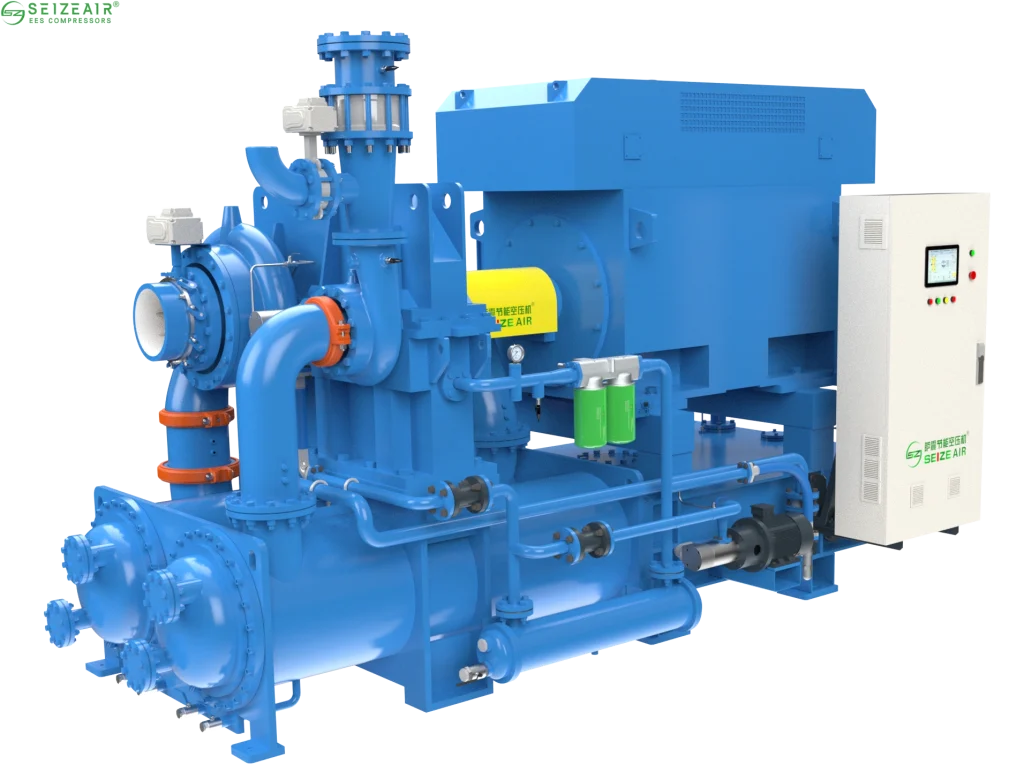

We hope this article provides clear, professional guidance for selecting between centrifugal and screw compressors. Seize is committed to delivering efficient, reliable, and energy-saving centrifugal air compressor solutions to global users. If you seek air compression equipment that balances performance and cost-effectiveness, Seize stands as your trusted partner.