In today’s manufacturing, construction, energy, and food processing industries, compressed air systems are the backbone of production. Choosing the right industrial air compressor supplier is about much more than buying a machine—it’s about securing expert guidance, installation, commissioning, and ongoing support to ensure smooth operations and cost efficiency over the long term.

This guide walks you through the services provided by industrial air compressor suppliers, the types of compressors available, energy-saving strategies, best practices for installation and maintenance, and real-world applications. We also highlight solutions from Seize, a trusted global brand, to illustrate practical outcomes.

Why Opt for a Full-Service Industrial Air Compressor Supplier?

When considering a supplier, price and specifications are only part of the picture. A professional industrial air compressor supplier typically offers end-to-end services:

- On-Site Audit

Conducting a thorough assessment of your current system is critical. Audits involve collecting operational data, identifying leaks, checking for wear, and reviewing energy use. A detailed report provides efficiency scores, suggested improvements, and projected ROI.

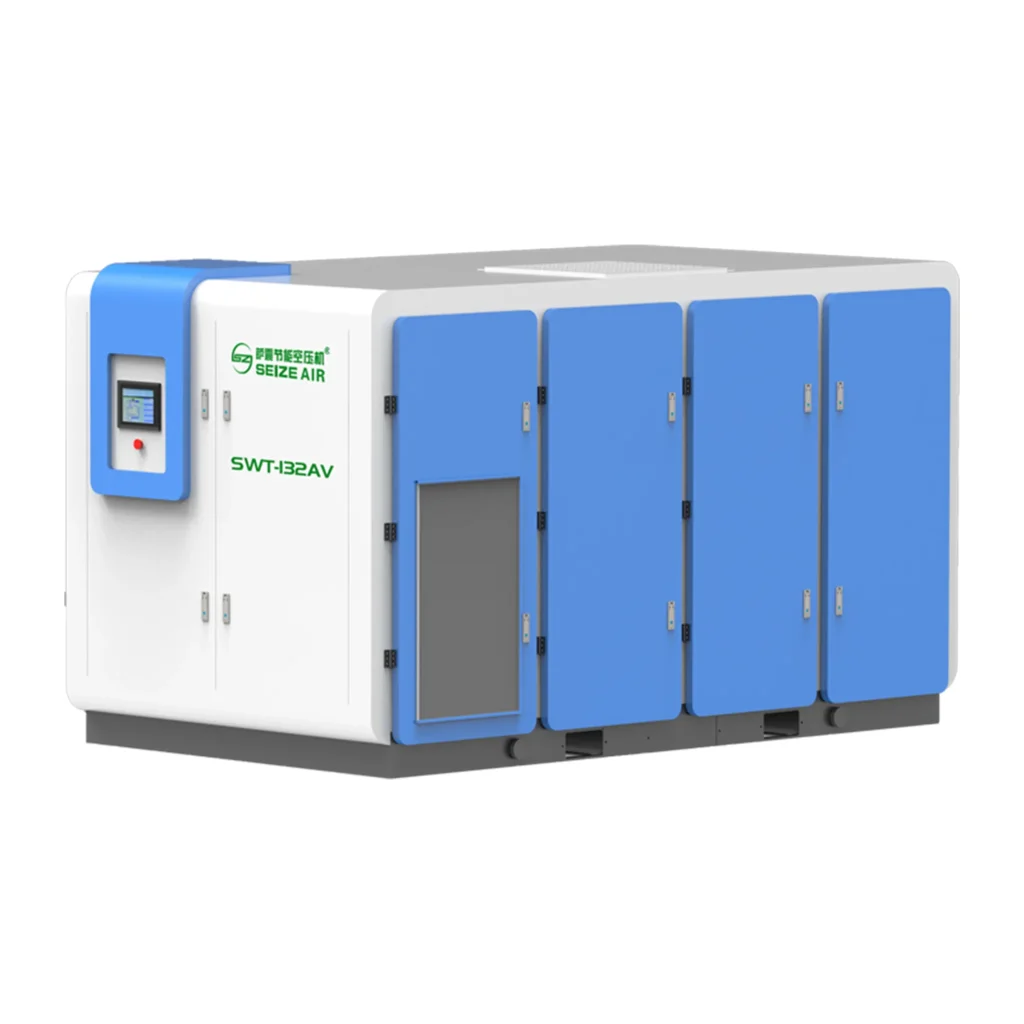

Seize offers smart auditing tools that quickly generate actionable energy-saving strategies, helping businesses optimize their compressed air systems effectively. - Equipment Selection and Custom Solutions

Based on production needs, pressure requirements, and environmental conditions, suppliers recommend the right compressor type—screw, centrifugal, or portable. Custom solutions might include variable frequency drives (VFDs), remote monitoring capabilities, or heat recovery systems. - Installation and Commissioning

This step ensures everything functions as designed: foundation setup, piping, electrical connections, commissioning, and testing under load.

With over 30,000 compressors installed worldwide, Seize installation teams provide practical, on-site solutions tailored to facility layouts. - Maintenance and Remote Monitoring

Ongoing maintenance covers filter changes, lubrication, inspections, and performance analysis. Remote monitoring allows real-time tracking of system health, enabling early fault detection and proactive maintenance. - Operator Training and Technical Support

Training staff to operate compressors safely and efficiently is crucial. Responsive technical support ensures minimal downtime.

Understanding Different Types of Industrial Air Compressors

Choosing the right type can greatly influence efficiency and operational stability. Here’s a practical comparison:

| Compressor Type | Power Range | Key Features | Typical Applications | Energy-Saving Notes |

|---|---|---|---|---|

| Screw Air Compressor | 15–500 HP | Efficient, continuous operation, quiet | Pharmaceuticals, food, electronics | VFDs, heat recovery |

| Piston Compressor | 5–100 HP | Best for intermittent operation | Automotive repair, spray painting | Auto-stop load control |

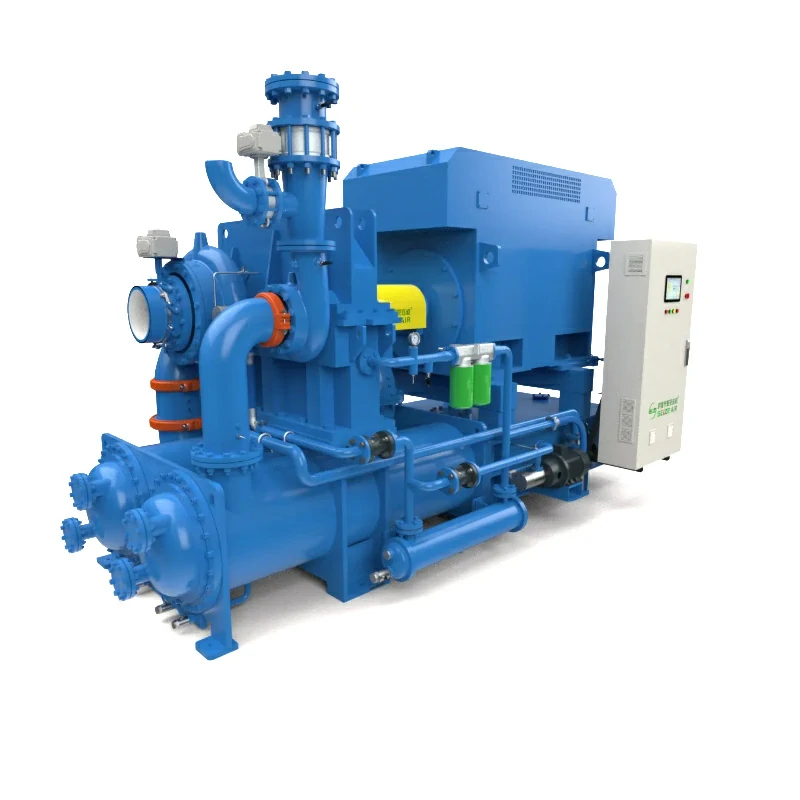

| Centrifugal Air Compressor | 200–2000 HP | High flow, large-scale industrial | Petrochemical, steel, energy | Multi-stage compression control |

| Portable Air Compressor | 10–200 HP | Flexible, mobile for temporary sites | Construction, temporary maintenance | Adjustable pressure, energy-saving mode |

Seize offers a full range of compressors across all categories, with customizable configurations to suit diverse industrial operations.

How to Procure an Industrial Air Compressor

Buying a compressor is a strategic decision that affects both efficiency and costs:

- Assess Air Demand

Calculate required flow and pressure for your production lines to avoid over- or under-sizing. - Consider Energy Costs

Factor in long-term electricity consumption and prioritize energy-efficient models. - Site Conditions Matter

Temperature, humidity, dust, and available space all influence equipment choice. - Maintenance Accessibility

Machines that are easy to service reduce downtime and keep operations running smoothly. - Choose a Reliable Brand

Trusted brands like Seize offer dependable support and long-term parts availability.

How Industrial Air Compressors Can Save Energy and Cut Costs

Compressed air often accounts for 10–20% of a facility’s electricity use. Implementing the right strategies can make a real difference:

- Detect and Repair Leaks

Surprisingly, leaks can waste around 20–30% of energy if left unaddressed. - Variable Frequency Drives & Load Management

Adjusting compressor speed according to real-time demand optimizes efficiency. - Intelligent Monitoring Systems

Tracking pressure, flow, and energy consumption helps managers make informed decisions. - Heat Recovery

Exhaust heat can be repurposed for space heating or process water, reducing utility costs. - Regular Energy Audits

Periodic system reviews identify inefficiencies and guide investment in upgrades.

Seize’s VSD screw compressors, combined with intelligent monitoring, have helped factories cut energy use by approximately 15–20%.

Installation Tips for Industrial Air Compressors

Proper installation ensures long-term reliability:

- Foundation & Vibration Isolation: Level, sturdy bases with vibration pads.

- Piping Layout: Avoid sharp bends and pressure drops for consistent airflow.

- Electrical & Safety: Comply with local codes; install protective switches and emergency stops.

- Commissioning & Testing: Gradually ramp up load and verify system performance.

Best Practices for Maintenance and Remote Monitoring

Regular care extends equipment life and prevents unexpected failures:

- Routine Maintenance

Replace filters, lubricants, belts, and other key components on schedule. - Preventive Maintenance

Monitor vibration and temperature trends to anticipate potential issues. - Remote Monitoring

Real-time insights allow for proactive service planning and efficiency improvements. - Spare Parts Management

Having essential parts on hand reduces downtime when issues arise.

Seize’s remote monitoring system lets managers track equipment status from any device, bringing predictive maintenance into daily operations.

Industry Trends Shaping Industrial Air Compressors

- Energy Efficiency: Rising electricity costs make efficient compressors a top priority.

- Smart, Connected Systems: IoT and cloud integration improve operational control.

- Modular & Custom Solutions: Tailored setups meet specific production needs.

- Sustainability: Heat recovery and eco-friendly designs are becoming standard practice.

Real-World Applications of Industrial Air Compressors

Electronics Manufacturing Facility – Screw Compressor Upgrade

The factory faced frequent downtime and rising energy bills. After a thorough audit, the team installed a Seize VSD screw compressor and provided staff training. Within a month, energy use dropped by around 18%, and uptime reached 98%.

Construction Site – Portable Compressor Deployment

A construction project required temporary high-pressure air on-site. A Seize portable compressor was deployed, piping arranged, and operators trained. Productivity increased by roughly 25%, and safety incidents were reduced.

Food Processing Plant – Centrifugal Compressor Energy Retrofit

Large centrifugal compressors were consuming excessive energy. By upgrading to a high-efficiency system and implementing remote monitoring, energy usage dropped about 12%, saving the facility approximately $200,000 annually.

How to Choose a Trusted Industrial Air Compressor Supplier

Key selection criteria:

- Comprehensive Service: From audit to ongoing maintenance, a full-service supplier is invaluable.

- Reliable & Efficient Equipment: Durable, energy-efficient compressors reduce costs over time.

- Responsive Technical Support: Fast assistance minimizes production disruptions.

- Customization Options: Solutions tailored to unique operational requirements.

- Proven Experience: Seize has sold over 30,000 compressors globally, offering reliable support and spare parts for the long term.

Conclusion

Partnering with a professional industrial air compressor supplier is a strategic investment. Through thorough audits, correct equipment selection, expert installation, smart maintenance, and energy management, businesses can achieve sustained operational efficiency and cost savings.

Seize provides end-to-end solutions that help companies build efficient, safe, and sustainable compressed air systems.