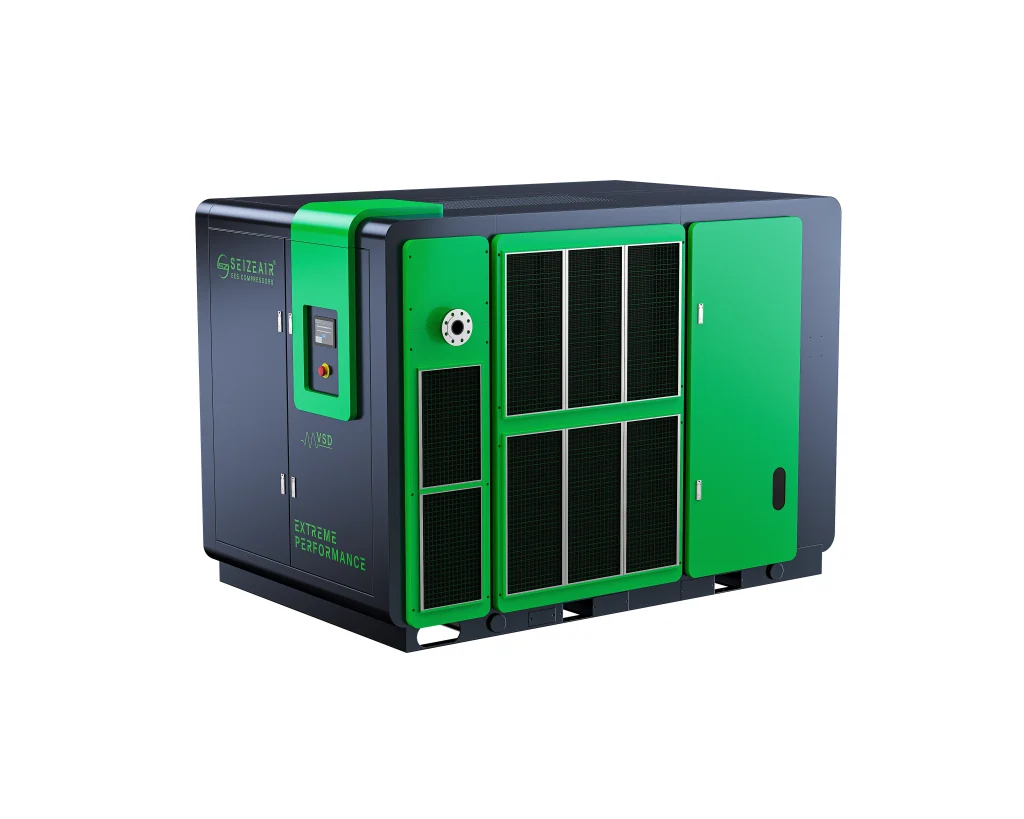

The Importance of High-Efficiency Air Compressors in Manufacturing and Industry

High-efficiency air compressors play a critical role in modern manufacturing, as air compression systems typically account for 10%–30% of a factory’s energy consumption. Any improvement in energy efficiency can significantly reduce costs. Traditional systems commonly suffer from low motor efficiency, significant leakage, and inefficient operation, leading to energy waste. High-efficiency models achieve lower energy consumption, more stable pressure output, and higher production efficiency through permanent magnet variable frequency technology, high-efficiency motors, and optimized structural design. With advantages like IE3/IE4 motors, advanced rotor profiles, and intelligent control systems, high-efficiency air compressors have become the preferred choice for equipment upgrades and energy-saving retrofits.

What Constitutes a “High-Efficiency” Air Compressor? (Technical Definition of High Efficiency)

A “high-efficiency” air compressor is not merely a synonym for energy-saving equipment but represents a systemic concept encompassing the unit’s motor, air-end, control system, and comprehensive plant-wide air circuit optimization. Selecting high-efficiency models requires understanding their technical definitions and standards.

High-Efficiency Standards (IE3/IE4 Motors, ISO Standards, etc.)

High-efficiency air compressors typically adopt international high-efficiency motor standards:

IE3/IE4 High-Efficiency Motors: 3%–8% more efficient than traditional IE1/IE2 motors, delivering significant long-term power savings.

ISO 1217 Air Delivery Standard: Ensures comparable air delivery metrics across units, enabling informed selection.

ISO 5199/ISO 7183 Reliability Standards: Guarantees stable performance during continuous industrial operation.

Only models adhering to these standards qualify as truly high-efficiency air compressors.

Energy-saving Advantages of Permanent Magnet Variable Speed Drive (PM VSD)

The permanent magnet variable speed drive system is a core technology of high-efficiency models, offering advantages including:

High-efficiency output: Permanent magnet synchronous motors eliminate rotor current losses, achieving efficiency of 96%–98%.

Load matching: Variable speed control adjusts rotation speed based on actual air demand, preventing idle energy consumption.

Soft start and smooth speed regulation: Reduces start-up current impact, extending equipment lifespan.

Significant Energy Savings: In industrial environments with high load fluctuations, PM VSD models achieve 20%–40% greater energy savings compared to fixed-speed units.

Through permanent magnet variable speed technology, high-efficiency air compressors deliver stable operation, energy efficiency, and simplified maintenance.

High-Efficiency Airend Structure and Energy-Saving Design

The airend is the core of compressor energy efficiency. Modern high-efficiency models feature significant structural improvements:

Optimized rotor profile: New profiles ensure more uniform meshing, reducing internal leakage and friction losses.

Optimized chamber dimensions: Longer or larger-diameter compression chambers enable the same air delivery at lower speeds, lowering energy consumption.

Improved bearing and cantilever design: Ensures stable high-speed rotation while reducing mechanical losses.

Through airend optimization, high-efficiency compressors maintain sustained high performance in actual production.

System-Level Efficiency

Energy savings in high-efficiency air compressors depend not only on the host unit but also on system-level optimization:

Pipeline layout optimization: Reducing elbows and selecting appropriate pipe diameters minimizes pressure loss.

Air receiver configuration: Buffering pressure fluctuations reduces compressor start/stop cycles.

Filtration and drying systems: Selecting low-pressure-drop filters and high-efficiency refrigerated dryers ensures air quality while lowering pressure drop.

Intelligent control: Real-time monitoring of pressure, flow, and current enables energy-efficient operation.

System-level optimization allows high-efficiency air compressors to fully leverage their energy-saving and reliability advantages in complex industrial environments.

Analysis of Typical Air Demand in Manufacturing and Industry

Within manufacturing and industrial settings, air compressor requirements vary significantly across factories and sectors. Accurately understanding air consumption characteristics is fundamental to selecting high-efficiency air compressors. This chapter analyzes industrial air demand from four perspectives: production modes, industry characteristics, scalability requirements, and operating environments.

Air Consumption Characteristics of Continuous vs. Intermittent Production

Industrial production falls into two categories: continuous and intermittent. Each mode imposes distinct demands on air compressors:

Continuous Production

In continuous operations like automotive manufacturing, textiles, and food filling lines, pneumatic equipment runs 24/7. Air demand is stable yet substantial.

Characteristics include:

Long peak load duration

Sensitivity to pressure fluctuations

High energy consumption

Intermittent Production

Intermittent production, such as electronics assembly or machining processes, sees air consumption fluctuate with process activation.

Characteristics include:

Significant load fluctuations

Frequent starts and stops

Efficiency challenges for fixed-frequency units

Businesses must select models matching their production patterns.

Industry-Specific Requirements for Pressure, Flow, and Cleanliness

Different industrial sectors have distinct standards:

Textile Industry: 6–8 bar

Food & Beverage: 5–7 bar, oil-free, ±0.05–0.1 bar

Automotive Manufacturing: 6–8 bar, oil-free for painting

Electronics: 4–6 bar, ultra-stable ±0.02–0.05 bar

Mining & Heavy Machinery: 10–15 bar, ±0.1–0.2 bar

Production Line Scalability Requirements (Future Capacity Planning)

Air Volume Reserve: 15%–30% excess

Modular Units: Facilitate future expansion

System Scalability: Piping and auxiliary units should support upgrades

Operating Environment and Duration

24/7 operation

Dust environments

High-temperature factory conditions

Core Selection Criteria for High-Efficiency Air Compressors

Selecting an appropriate high-efficiency air compressor requires comprehensive evaluation of multiple core metrics that determine the unit’s performance, energy savings, and stability in actual production. This chapter focuses on analyzing key selection parameters including air delivery, pressure, energy efficiency, variable vs. fixed frequency, motor technology, as well as noise, heat dissipation, and installation space.

How to Calculate Airflow (Flow/Capacity)?

Airflow is the most fundamental parameter of an air compressor, determining whether the unit can meet the air supply demands of the production line. Improper selection of airflow can lead to insufficient air pressure or energy waste.

Airflow Calculation Method

- Analyze Air-Using Equipment: Compile the rated air consumption of all pneumatic equipment in the factory (e.g., spray painting robots, pneumatic tools, packaging machinery).

- Consider the simultaneous usage factor: Not all equipment operates at full load simultaneously on a production line. Typically, a simultaneous usage factor of 0.6–0.8 is applied.

- Reserve for peak air demand: Account for future expansion or temporary peak loads by reserving 15%–30% of the air delivery capacity.

Formula example:

Total air consumption = ∑_(i=1)^n Device rated air consumption × Simultaneous usage factor × Safety factor

Scientific calculation of air consumption prevents unit overload or prolonged underutilization, thereby enhancing the energy efficiency and lifespan of high-efficiency air compressors.

Pressure Selection (Pressure/PSI/BAR)

Pressure is a key parameter influencing the efficiency, performance, and equipment compatibility of air compressors. Incorrect pressure selection can cause energy waste, insufficient supply, or damage to pneumatic equipment.

Selection Principles:

- Identify the maximum working pressure of all pneumatic equipment.

- Consider pressure losses in the pipeline, filters, dryers, and fittings. Typically, a 10%–15% margin is recommended.

- Match compressor pressure with system requirements: Excessive pressure increases energy consumption; insufficient pressure affects production quality.

High-efficiency compressors with variable-frequency drive (VSD) can dynamically adjust pressure setpoints, reducing wasted energy during periods of low demand.

Energy Efficiency Indicators (kW/m³/min, Specific Power Consumption)

Evaluating compressor energy efficiency relies on specific power consumption metrics:

- Specific power (kW/m³/min): Lower values indicate higher efficiency.

- Load range energy efficiency: Fixed-speed units may consume significant energy at partial loads; VSD units maintain high efficiency across varying loads.

- Energy savings over lifecycle: Consider energy cost over 5–10 years compared to initial purchase cost.

High-efficiency compressors generally achieve 0.45–0.55 kW per m³/min for oil-injected screw compressors and 0.40–0.50 kW per m³/min for PM VSD models.

Fixed Frequency vs. Variable Frequency Selection

Variable-frequency (VSD) compressors provide superior energy-saving performance in fluctuating demand scenarios, while fixed-frequency units are simpler and more cost-effective for stable demand environments.

Comparison:

| Feature | Fixed Frequency | Variable Frequency (VSD) |

|---|---|---|

| Initial Cost | Lower | Higher |

| Energy Savings | Low at part load | High at part load |

| Load Adaptation | Limited | Automatic matching to demand |

| Maintenance | Simpler | Requires inverter maintenance |

| Noise & Vibration | Constant | Reduced at low load |

Selection should be based on production patterns, load fluctuation, and budget considerations.

Motor and Drive Technology (Permanent Magnet, Synchronous Motors)

The choice of motor directly affects energy efficiency and reliability:

- Permanent magnet synchronous motors (PMSM): Efficiency up to 96%–98%, suitable for continuous and fluctuating loads.

- IE3/IE4 high-efficiency motors: Comply with international energy standards, ensuring long-term energy savings.

- Integrated drive systems: Combining motor, inverter, and control reduces losses and improves system stability.

High-efficiency air compressors using PMSM and advanced drive technology can maintain efficiency even in partial load operation.

Noise, Heat Dissipation, and Installation Space Considerations

- Noise: Modern high-efficiency compressors are designed with acoustic insulation, reducing noise to 65–70 dB in industrial environments.

- Heat dissipation: Proper cooling (air or water) ensures motor and airend longevity. Heat recovery systems can utilize waste heat for facility heating.

- Installation space: Compact, modular designs facilitate installation, maintenance, and future expansion.

These factors impact operational comfort, maintenance cost, and overall system efficiency.

Maintenance and Operational Considerations for High-Efficiency Air Compressors

Even the most efficient compressors require proper operation and maintenance to sustain energy savings and reliability.

Daily Operation Checks

- Monitor operating pressure, flow, and motor current.

- Inspect air filters, oil levels, and cooling systems.

- Ensure proper functioning of VSD controllers and sensors.

Preventive Maintenance

- Schedule oil and filter replacements according to manufacturer specifications.

- Inspect airend and bearings for wear and lubrication quality.

- Regularly calibrate pressure sensors and controllers.

Troubleshooting Common Issues

- Pressure fluctuations: Check for leaks, insufficient air receiver capacity, or control system errors.

- Overheating: Inspect cooling system, clean heat exchangers, and ensure ambient temperature within limits.

- Excessive energy consumption: Re-evaluate load profile, VSD settings, and pipeline design.

Proper operational management ensures high-efficiency compressors maintain performance and energy savings over the long term.

Case Studies: High-Efficiency Compressor Applications in Industry

Automotive Manufacturing

A mid-sized automotive plant upgraded to PM VSD high-efficiency compressors to supply assembly lines and paint booths. Energy consumption reduced by 25%, pressure stability improved from ±0.2 bar to ±0.05 bar, and maintenance costs decreased due to fewer start-stop cycles.

Food & Beverage Industry

A beverage bottling factory adopted oil-free high-efficiency compressors with intelligent control. The factory experienced energy savings of 18%, improved air quality for filling lines, and avoided product contamination incidents.

Mining and Heavy Equipment

A mining site replaced aging fixed-speed compressors with modular PM VSD units. The modular approach allowed load sharing and redundancy, providing continuous high-pressure air while reducing peak energy demand by 30%.

These cases demonstrate that proper selection and implementation of high-efficiency compressors significantly impact cost savings, production stability, and equipment longevity.

Conclusion

Amidst global manufacturing and industrial upgrades, selecting a high-efficiency air compressor truly suited to your operational conditions impacts not only energy efficiency and costs but also long-term competitiveness. Proper selection, professional system configuration, and reliable after-sales support are essential to ensure air compressors operate at peak efficiency to meet production demands. If you seek more reliable, energy-efficient, and globally proven air compression solutions, Seize—a compressor brand with years of industry expertise—provides mature, high-performance equipment and technical support for businesses of all sizes and industries. We empower enterprises to achieve sustained production stability and energy optimization.