Understanding the main components of an air compressor and their functions is essential for maintaining optimal performance and efficiency. By learning how these parts work together, operators can improve reliability, extend equipment lifespan, and quickly identify the causes of common issues. This guide will walk you through the critical components of an air compressor, their roles, frequent problems, and practical maintenance advice.

Major Components of an Air Compressor and Their Functions

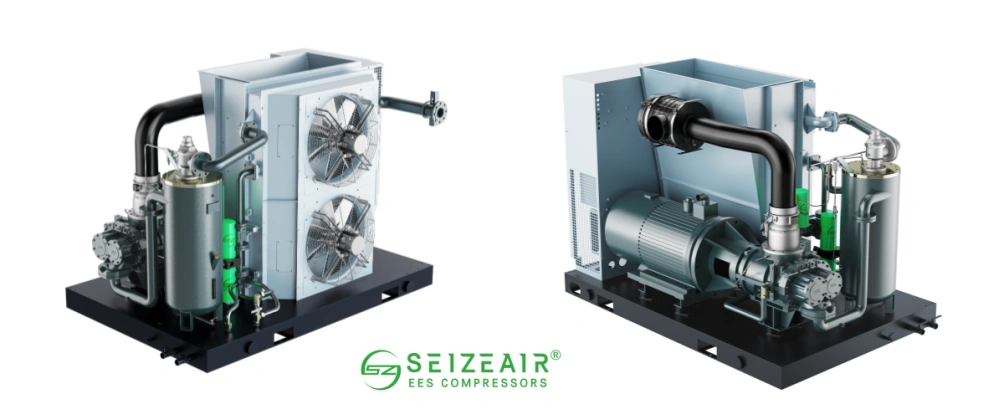

- Airend (Compressor Element)

- Function: The heart of the compressor that compresses air.

- Common Issues: Wear and tear, oil leakage, reduced efficiency.

- Maintenance Tip: Regularly monitor operating temperature and replace worn bearings.

- Electric Motor

- Function: Provides the power to drive the compressor element.

- Common Issues: Overheating, voltage imbalance, bearing failure.

- Maintenance Tip: Ensure proper alignment, check electrical connections, and lubricate bearings as recommended.

- Air Intake Filter

- Function: Filters dust and contaminants before air enters the compressor.

- Common Issues: Clogging, reduced airflow, pressure drop.

- Maintenance Tip: Replace filters regularly to protect the airend.

- Oil Separator (in lubricated models)

- Function: Separates oil from compressed air.

- Common Issues: High oil carryover, clogging, pressure increase.

- Maintenance Tip: Replace separator elements at scheduled intervals.

- Cooling System (Air or Water Cooled)

- Function: Removes heat generated during compression.

- Common Issues: Scaling, blocked airflow, overheating.

- Maintenance Tip: Clean coolers regularly and check water quality in water-cooled systems.

- Control System & Sensors

- Function: Monitors pressure, temperature, and system health.

- Common Issues: Sensor failure, incorrect readings.

- Maintenance Tip: Calibrate sensors and update software if applicable.

Common Problems and How to Address Them

- Excessive Noise: May indicate loose parts, worn bearings, or improper installation.

- Oil Carryover: Often caused by a faulty separator or high oil level.

- Overheating: Can result from poor ventilation, dirty coolers, or low oil levels.

- Pressure Drops: Usually due to clogged filters or leaks in the system.

By knowing which part is responsible, troubleshooting becomes much faster and more accurate.

Maintenance Methods and Recommendations for Critical Parts

- Airend: Inspect bearings, check alignment, and replace worn rotors if efficiency drops.

- Motor: Monitor temperature and vibration; schedule bearing replacement before failure.

- Filters: Change intake filters and oil filters at manufacturer-recommended intervals.

- Oil Separator: Replace based on pressure differential or operating hours.

- Cooling System: Flush water-cooled systems and clean fins on air-cooled units regularly.

Preventive maintenance not only avoids costly breakdowns but also ensures consistent air quality.

Why Choosing Genuine Air Compressor Parts Matters

Using original parts from the manufacturer guarantees:

- Longer equipment life – Genuine parts are designed to match the exact specifications of your compressor.

- Better efficiency – Reduces energy consumption and improves output.

- Lower risk of breakdowns – Prevents premature wear and safety hazards.

- Compliance with warranty – Many warranties require the use of authentic components.

Get Expert Help with Air Compressor Parts and Solutions

Understanding the key components of an air compressor and their functions can help you boost performance, prevent downtime, and reduce repair costs. However, for complex issues and professional maintenance, expert guidance is invaluable.