Introduction

Noise is no longer a secondary consideration when selecting an air compressor. For workshops, laboratories, and noise-sensitive environments, choosing the right low noise air compressor directly affects safety, productivity, and long-term operating comfort.

Why Noise Control Matters in Air Compressor Selection

A low noise air compressor is not just about comfort. In many environments, excessive noise leads to:

- Operator fatigue and reduced concentration

- Compliance risks with workplace noise regulations

- Limitations on equipment placement

- Lower overall productivity

In laboratories, medical facilities, and precision workshops, noise can interfere with measurements, communication, and sensitive processes. This is why low noise air compressor selection has become a primary decision factor rather than an afterthought.

Understanding Noise Ratings in Air Compressors

Decibel Levels Explained

Noise levels are typically measured in decibels (dB), but many buyers misunderstand what these numbers represent.

As a general reference:

- 40–50 dB: Quiet office environment

- 50–60 dB: Normal conversation

- 60–70 dB: Busy workshop

- 70+ dB: Prolonged exposure may cause fatigue

A true low noise air compressor for indoor use usually operates below 60 dB, measured at a standard distance.

Why Manufacturer Noise Claims Can Be Misleading

Some manufacturers list noise levels measured under ideal conditions, not real-world operation. Factors that increase actual noise include:

- Load level

- Installation surface

- Room acoustics

- Vibration transfer through piping

For SEO and buyer trust, it is important to explain that real operating noise matters more than brochure figures.

Key Design Factors That Reduce Compressor Noise

Compressor Type and Operating Principle

Different compressor technologies inherently produce different noise levels.

- Oil-free piston compressors: Low to moderate noise, suitable for labs and light workshops

- Rotary screw compressors: Lower noise than piston under continuous operation

- Magnetic bearing compressors: Among the quietest options due to minimal mechanical contact

Low noise air compressors increasingly rely on design-level noise reduction rather than external soundproofing alone.

Vibration Control and Structural Design

Noise and vibration are closely related. Poor vibration control amplifies sound through floors and walls.

Effective low noise air compressor designs typically include:

- Precision-balanced rotating components

- Vibration-isolated mounting systems

- Rigid yet dampened frames

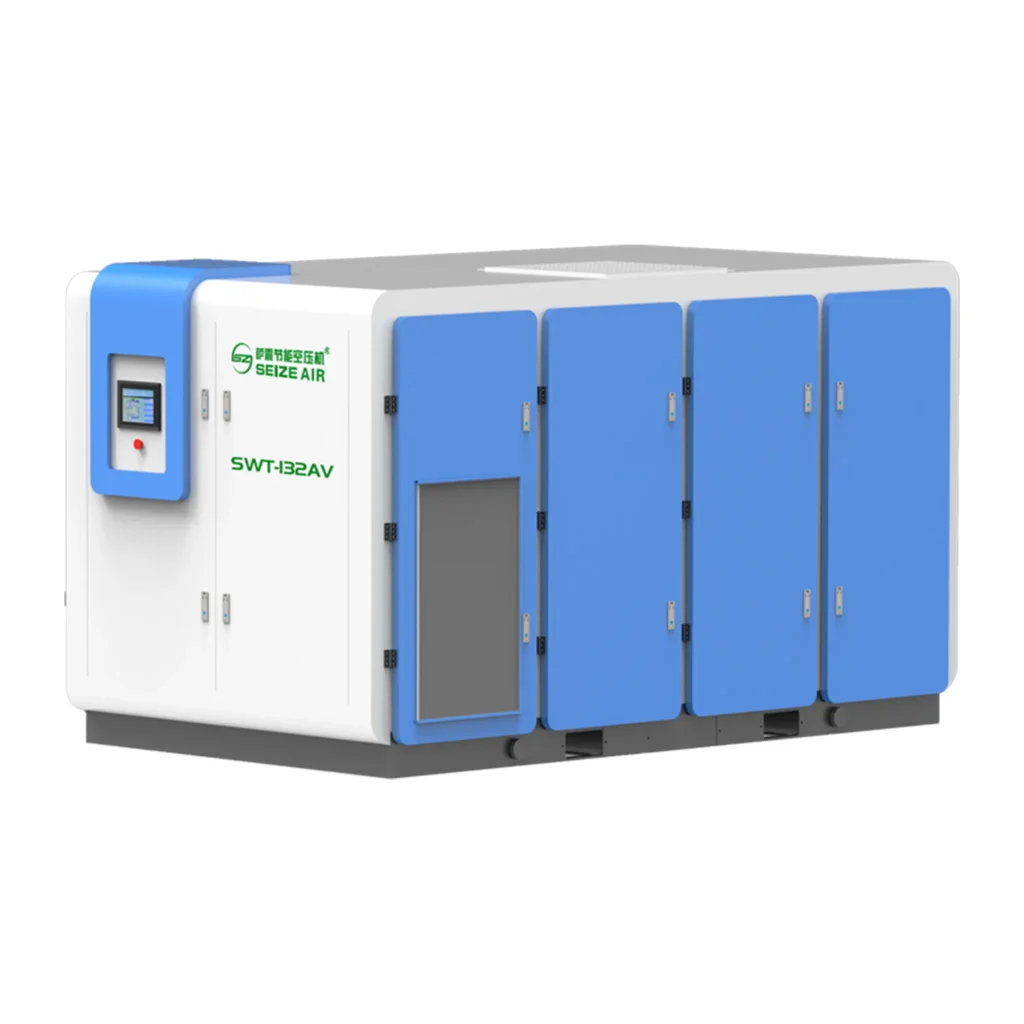

Some industrial compressor designs—such as those adopted by Seize in low-noise continuous-operation models—focus heavily on vibration control to reduce both airborne and structure-borne noise.

Low Noise Air Compressor Options by Application

| Application | Noise Requirement | Recommended Compressor | Reason |

|---|---|---|---|

| Laboratory | ≤55 dB | Oil-free / magnetic bearing | Low vibration |

| Workshop | ≤60 dB | Low noise rotary screw | Continuous operation |

| Medical | Ultra-low | Oil-free system | Clean & quiet |

Low Noise Air Compressor for Workshops

Workshops often require a balance between performance and noise control.

Key requirements:

- Stable airflow for tools

- Acceptable noise levels for long work shifts

- Compact footprint

Rotary screw compressors with integrated sound enclosures are commonly selected as low noise air compressors for workshops, especially where compressors operate for extended periods.

Low Noise Air Compressor for Laboratories

Laboratories demand stricter noise and air quality standards.

Typical priorities include:

- Ultra-low noise output

- Oil-free air supply

- Minimal vibration

Oil-free and magnetic bearing air compressors are increasingly used in lab environments where noise and contamination must be minimized simultaneously.

Low Noise Air Compressor for Medical and Clean Environments

In medical and cleanroom settings, noise is closely tied to patient comfort and equipment accuracy.

Low noise air compressors in these environments often feature:

- Oil-free compression

- Redundant safety controls

- Advanced noise dampening

This is one reason manufacturers like Seize position certain low noise compressor systems specifically for clean and sensitive applications rather than general industrial use.

Real-World Application Case

Case Overview

- Environment: Precision machining workshop

- Challenge: Excessive noise from legacy piston compressors

- Operating Hours: 10–12 hours per day

Solution

The workshop transitioned to a low noise rotary screw air compressor featuring:

- Integrated sound enclosure

- Improved vibration isolation

- Stable pressure control

Result

- Noise levels reduced to below 60 dB

- Improved operator comfort

- Higher tool efficiency due to stable air supply

This scenario reflects why low noise air compressors are increasingly seen as productivity tools, not just comfort upgrades.

Energy Efficiency and Noise

Noise often increases when compressors operate inefficiently.

Common causes include:

- Frequent load/unload cycling

- Oversized compressors running inefficiently

- Poor airflow management

High-efficiency compressors tend to operate more smoothly and quietly. This is why low noise air compressor selection should always consider energy efficiency and control systems together.

Some continuous-duty compressor designs—such as those developed by Seize—optimize both efficiency and noise reduction simultaneously, rather than treating noise as a secondary concern.

Maintenance Considerations for Low Noise Air Compressors

Low noise does not mean maintenance-free.

Key maintenance factors include:

- Filter cleanliness (clogged filters increase noise)

- Bearing condition

- Cooling airflow integrity

Neglecting maintenance often leads to gradual noise increases, even in compressors originally designed for quiet operation.

Common Mistakes When Selecting a Low Noise Air Compressor

- Relying solely on advertised dB values

- Ignoring vibration transmission through floors

- Oversizing the compressor unnecessarily

- Choosing sound enclosures without addressing internal noise sources

- Overlooking long-term maintenance impact on noise levels

Avoiding these mistakes ensures both immediate and long-term noise control.

How to Evaluate Low Noise Air Compressor Suppliers

When comparing suppliers, assess:

- Real-world noise data availability

- Experience with noise-sensitive applications

- Design focus on vibration and airflow

- Long-term support and service capability

Suppliers with experience in continuous-duty and low-noise system design—such as Seize—tend to offer more reliable solutions for demanding indoor environments.

Conclusion

Choosing the right low noise air compressor improves comfort, compliance, and operational efficiency. Matching compressor design to application requirements is essential for long-term success.