Introduction

In modern manufacturing and industrial operations, a consistent supply of compressed air is essential for productivity and ensuring the longevity of equipment. Using a screw air compressor ensures stable operations, high efficiency and reduced energy costs. SEIZ air compressors are designed to meet the diverse demands of various industries, ranging from cost-effective oil-injected solutions to ultra-clean oil-free systems.

Oil-Injected Screw Air Compressors: Cost-Effective and Robust

Oil-injected screw compressors are widely used in the manufacturing, automotive and construction industries. Their ability to deliver high airflow rates of 20–100 m³/min at pressures between 7 and 13 bar makes them ideal for CNC machines, pneumatic tools, painting lines and sandblasting operations.

SEIZE’s oil-injected models are designed for continuous performance with minimal downtime. Advanced rotor design reduces friction and wear, lowering maintenance costs while maintaining energy efficiency. Their robust construction ensures reliable operation, even in challenging factory environments.

Applications:

- Automotive: Painting, assembly lines

- Construction: Jackhammers, sandblasting

- Manufacturing: CNC machining, pneumatic tools

Benefits of SEIZE:

- High airflow and stable pressure output

- Extended maintenance intervals

- Energy-saving performance

Oil-Free Air Compressors: Ensuring Clean and Safe Production

Oil-free air compressors are indispensable for industries requiring contamination-free air, such as pharmaceuticals, food and drink, and electronics. SEIZ oil-free screw compressors meet ISO 8573-1 Class 0 standards, providing 100% oil-free air.

These quiet (<75 dB) compressors are highly energy-efficient thanks to IE5 PM motors and variable-speed technology. SEIZE also integrates IoT monitoring to optimise load management and reduce energy consumption by 10–20%.

Applications:

- Pharmaceuticals: Sterile air for drug production

- Food & Beverage: Packaging and fermentation

- Electronics: Chip fabrication and cleanrooms

Benefits of SEIZE:

- Zero oil contamination

- Low noise and energy-efficient

- Real-time monitoring for predictive maintenance

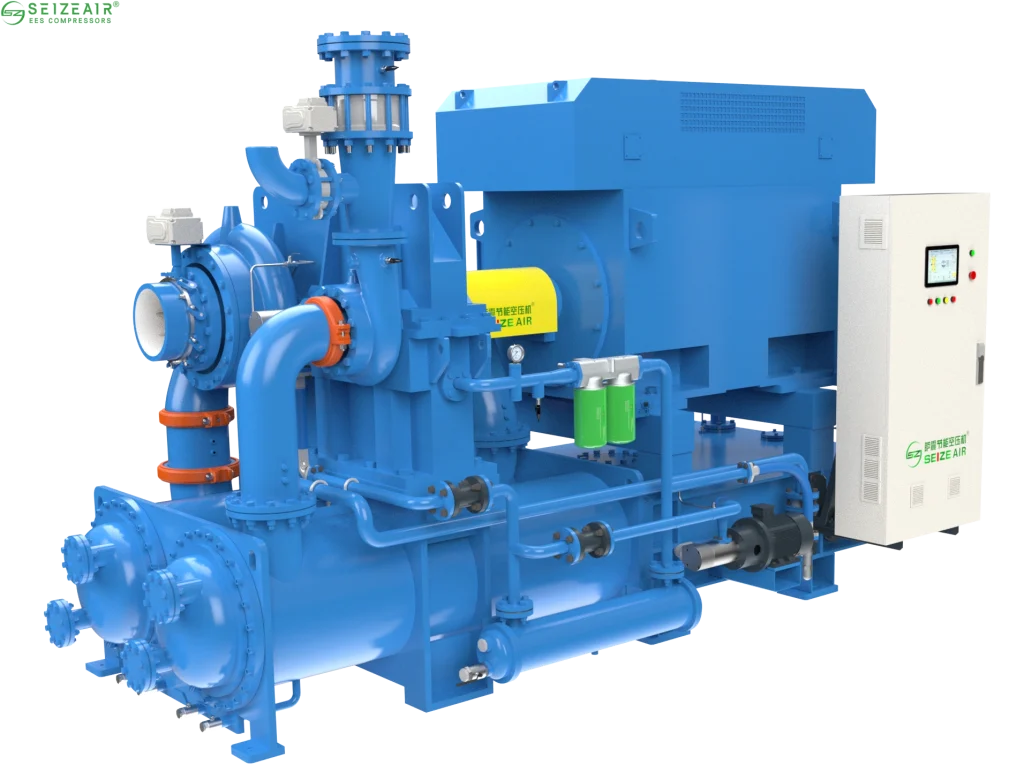

Centrifugal Air Compressors and Blowers: Ultra-High Flow for Large-Scale Operations

Centrifugal compressors and blowers are essential components of power plants, petrochemical facilities and large-scale HVAC systems. These machines deliver ultra-high airflow rates of over 100 m³/min while minimising maintenance requirements.

SEIZE centrifugal units feature precision-engineered rotors with advanced coatings to extend their service life. Their energy-efficient design ensures reliable performance in continuous, high-demand applications.

Applications:

- Power plants

- Petrochemical facilities

- Large-scale HVAC systems

Benefits of SEIZE:

- Ultra-high airflow with stable pressure

- Low maintenance and long service intervals

- Energy-efficient design with IoT-enabled monitoring

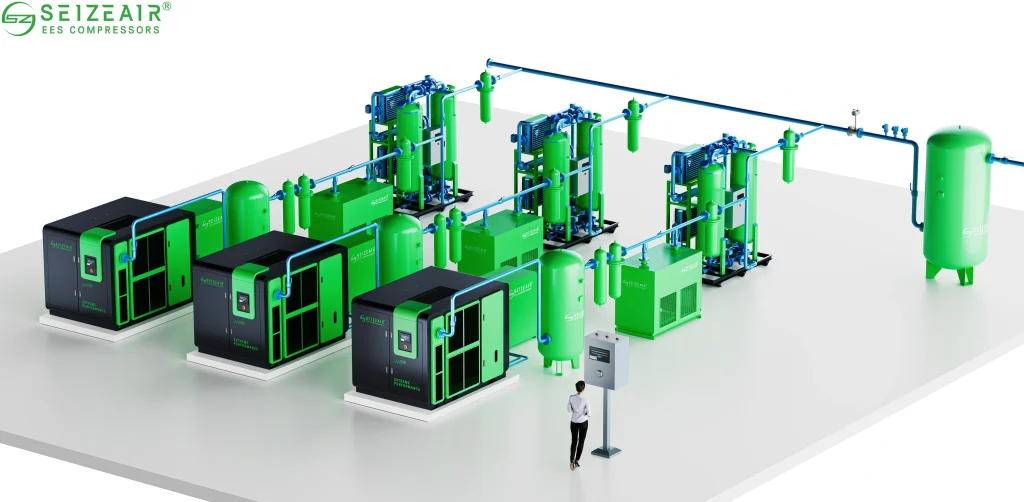

Air Compressor Downstream Equipment: Optimizing Performance and Reliability

Critical for maintaining air quality and protecting production machinery, downstream equipment includes air dryers, filters, and storage tanks. SEIZE offers a comprehensive range of downstream solutions designed to complement its compressors and ensure the supply of clean, dry and stable air throughout industrial processes.

Applications:

- Compressed air treatment in factories

- Protection of pneumatic tools and machinery

- Ensuring consistent product quality

Benefits of SEIZE:

- Efficient moisture and contaminant removal

- Reduced wear on machinery

- Seamless integration with SEIZE compressors for optimized performance

Conclusion

Choosing the right screw air compressor is essential for efficient, reliable, and cost-effective industrial operations. SEIZE offers a wide range of compressors—from oil-injected to oil-free and centrifugal models—paired with advanced downstream equipment. With energy-efficient designs, extended service intervals, and global support, SEIZE ensures your compressed air system delivers maximum performance while minimizing operational costs.