Air compressors are vital machines in industrial operations, but like any mechanical equipment, they require proper care to perform at their best. Regular maintenance not only extends the lifespan of your compressor but also ensures higher efficiency, lower operating costs, and fewer breakdowns.

At Seize Air, we are here to help you every step of the way — from simple maintenance tips and complete checklists to comprehensive service plans tailored to your needs.

Why Air Compressor Maintenance Matters

Neglecting maintenance can lead to reduced efficiency, unexpected downtime, and costly repairs. On the other hand, a well-maintained compressor delivers consistent air output, optimized energy consumption, and long-term reliability.

Seize Air offers expert support and guidance to ensure your equipment runs smoothly throughout its service life.

Key Maintenance Practices for Air Compressors

1. Always Use Genuine Spare Parts

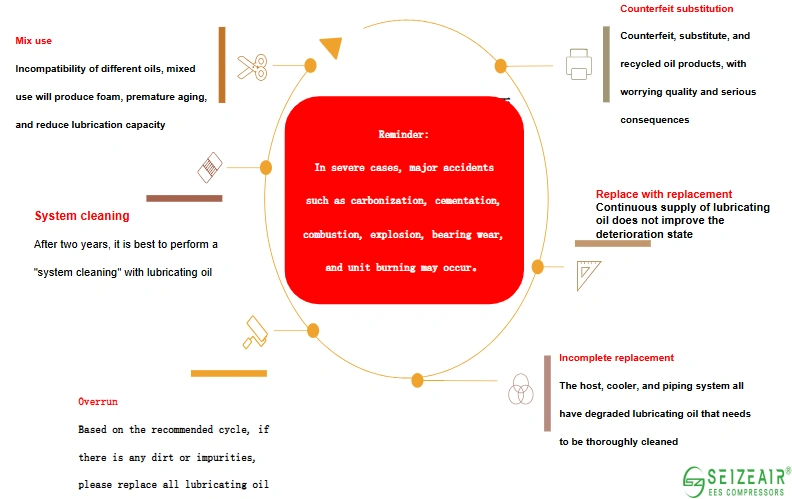

Using original spare parts is the foundation of reliable compressor maintenance. Genuine parts are engineered for durability, safety, and performance, while counterfeit or incompatible components can cause premature wear and void your warranty.

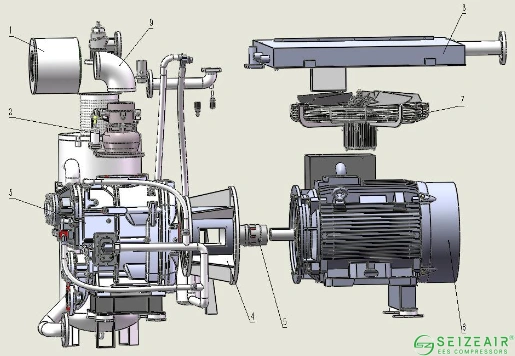

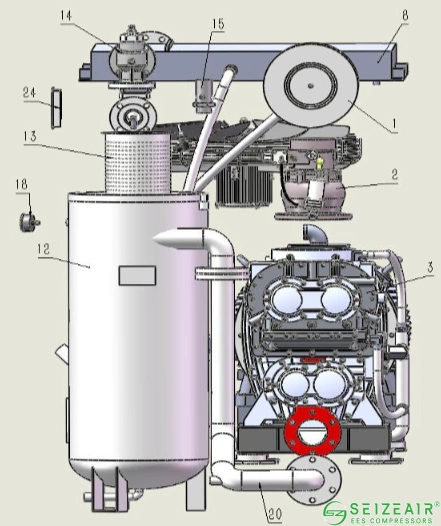

1.Air Filter

2.Intake Valve Solenoid Valve

3.Compressor

4.Center Bracket

5.Coupling

6.Motor

7.Fan

8.Cooler

9.Intake Hose

10.Inverter

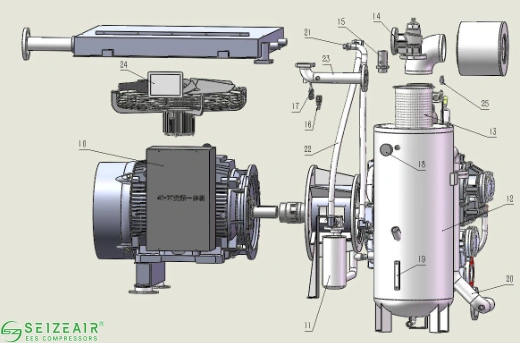

11.Oil Filter

16.Pressure Sensor

17.Temperature Sensor

19.Oil Viewing Mirror

21.Cooling oil inlet pipe

22.Cooling oil outlet pipe

23.Cooler intake pipe

25.Return check valve

12.Oil and Gas Drum

13.Oil Separator

14.MPV

15.Safety Valve

18.Pressure Gage

20.Compressor Exhaust Pipe

24.HMI

Seize Air SVC 75A-Ⅱ/8.5 Main Parts Manual

2. Perform Regular Inspections

Routine inspections help detect early warning signs of potential issues. By checking oil levels, filters, pressure, and unusual noises, you can prevent small problems from becoming major failures. We recommend setting up a scheduled inspection plan based on your compressor’s workload and operating environment.

3. Follow a Maintenance Checklist

A structured air compressor maintenance checklist ensures nothing is overlooked. This includes:

- Daily checks of oil level and condensate drainage

- Weekly cleaning and noise inspections

- Scheduled filter and lubricant replacements

- Annual safety valve testing and system checks

At Seize Air, we provide customized maintenance schedules to keep your operations running without interruption.

Get Expert Help from Seize Air

Whether you need spare parts, preventive maintenance, or a complete service program, Seize Air is your trusted partner. Our experts are ready to provide free consultation and guide you toward the best solutions for your specific needs.

👉 Contact Seize Air today for expert air compressor maintenance support and free advice.