1. What is an industrial air compressor used for?

Industrial air compressors power a wide range of applications such as pneumatic tools, automation systems, packaging lines, and painting. They are essential in industries like manufacturing, automotive, and food processing. Seize Air screw compressors provide stable and efficient air supply, ensuring reliable performance in demanding industrial environments.

Industrial screw air compressor powering pneumatic tools in a factory workshop

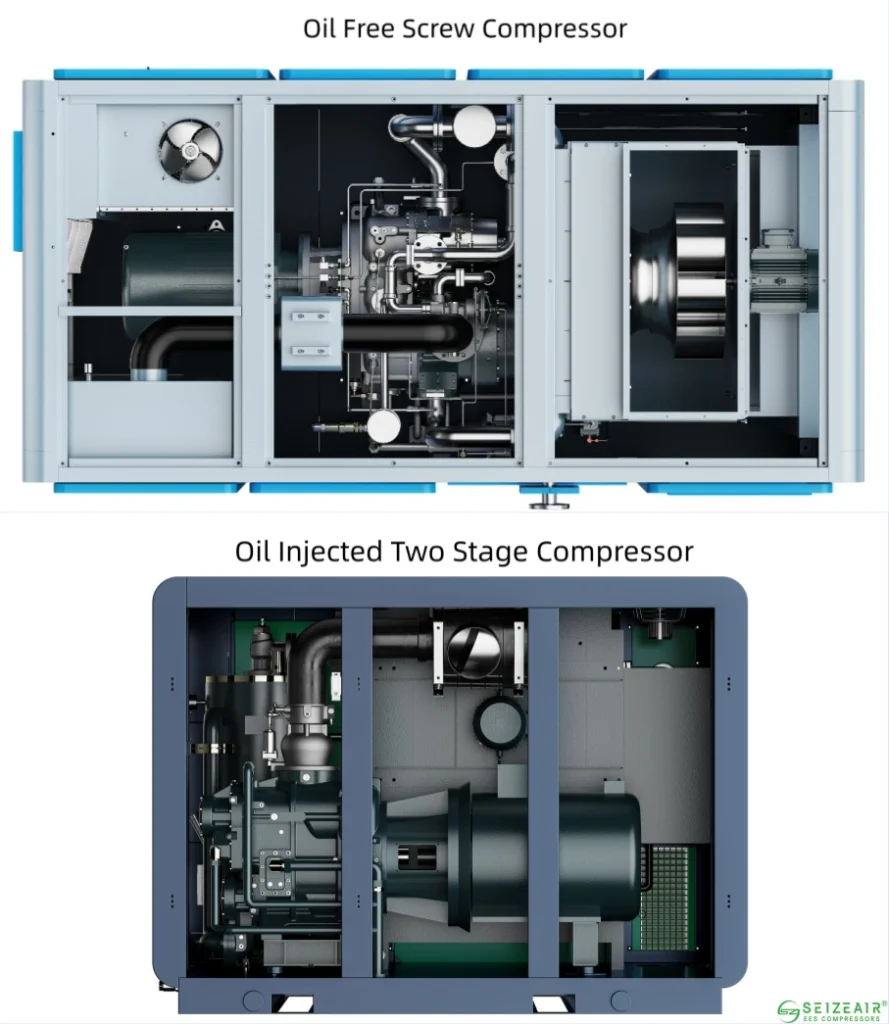

2. What is the difference between oil-free and oil-injected screw compressors?

Oil-injected compressors are durable and suitable for heavy-duty use, while oil-free compressors deliver 100% clean air, required in sensitive industries. Seize Air provides both oil-injected and oil-free screw compressors, helping customers meet diverse industry requirements.

3. How do I choose the right air compressor size for my factory?

Choosing the right compressor depends on air volume (CFM), pressure, and usage. Oversizing wastes energy; undersizing leads to low efficiency. Seize Air engineers provide customized air solutions, ensuring energy savings and stable production.

4. How can I reduce energy consumption in my air compressor system?

Up to 70% of compressor lifecycle cost comes from energy. Using VSD compressors, leak detection, and proper maintenance helps cut bills. Seize Air VSD screw compressors save up to 30% energy, making factories more sustainable.

5. What industries need oil-free compressed air?

Electronics, medical, food, and pharmaceuticals require oil-free air to ensure safety and quality. Seize Air oil-free screw compressors deliver ISO Class 0 clean air, protecting sensitive processes.

6. How often should an air compressor be serviced?

Regular maintenance is key. Filters should be checked monthly, oil every 2,000 hours, and major service at 8,000 hours. Seize Air compressors are designed for easy maintenance, reducing downtime and costs.

7. What is the lifespan of an industrial air compressor?

With proper care, compressors last 10–15 years or more. Quality and maintenance determine durability. Seize Air compressors are built with premium components, ensuring long service life and reliability.

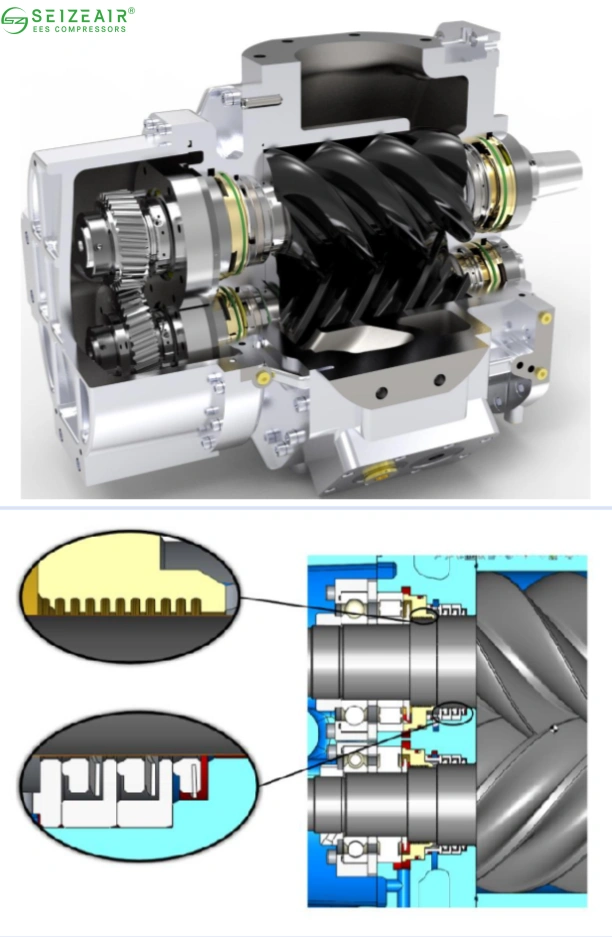

8. How does a screw air compressor work?

Screw compressors use two rotors to compress air continuously, delivering stable airflow with low noise. Seize Air screw compressors are engineered for efficiency, suitable for 24/7 factory operation.

Internal rotor design of screw air compressor showing air compression process

9. What are the key factors to consider when buying an air compressor?

Air demand, pressure, efficiency, maintenance, and cost are the main factors. Seize Air offers tailored solutions, ensuring the right balance of performance and investment.

10. Why should I choose Seize Air compressors over other brands?

Seize Air is a trusted manufacturer offering durable, energy-efficient compressors with global service support. Our solutions reduce operational costs and ensure long-term reliability for industrial customers worldwide.