In today’s industrial landscape, compressed air plays a critical role across many sectors. One of the key machines used to generate large volumes of air at moderate to high pressures is the centrifugal air compressor. In this article, we explore what a centrifugal air compressor is, the main types, how it works, and its applications — with an emphasis on SEO-friendly content for the keyword “centrifugal air compressor”.

Definition of a Centrifugal Air Compressor

A centrifugal air compressor is a dynamic (turbodynamic) compression machine that increases the pressure of air (or gas) by converting its kinetic energy into potential (pressure) energy.

Unlike positive-displacement compressors (such as reciprocating or screw compressors), which trap and compress a fixed volume, a centrifugal compressor accelerates the air using a rapidly spinning impeller and then slows it down in a diffuser to raise the pressure.

Key features of the centrifugal air compressor:

- Continuous airflow rather than discrete “batches”.

- Uses impellers and diffusers to accelerate and decelerate the air, converting velocity to pressure.

- Suited for large flow rates and consistent pressure delivery.

In short: the centrifugal air compressor is the go-to option when you need high flow and steady pressure, especially for industrial applications.

How Does a Centrifugal Air Compressor Work

Understanding the working principle helps clarify why the centrifugal air compressor is chosen in many scenarios.

Working Principle of Centrifugal Air Compressor

- Air enters the compressor at the eye (centre) of the rotating impeller.

- The impeller spins at high speed, imparting kinetic energy to the air, driving it radially outward by centrifugal force.

- The high-speed air then enters a diffuser or volute where its velocity is reduced (decelerated), converting kinetic energy into pressure energy .

- Depending on the pressure requirement, multiple stages (impeller + diffuser sequences) may be used to achieve the desired pressure rise.

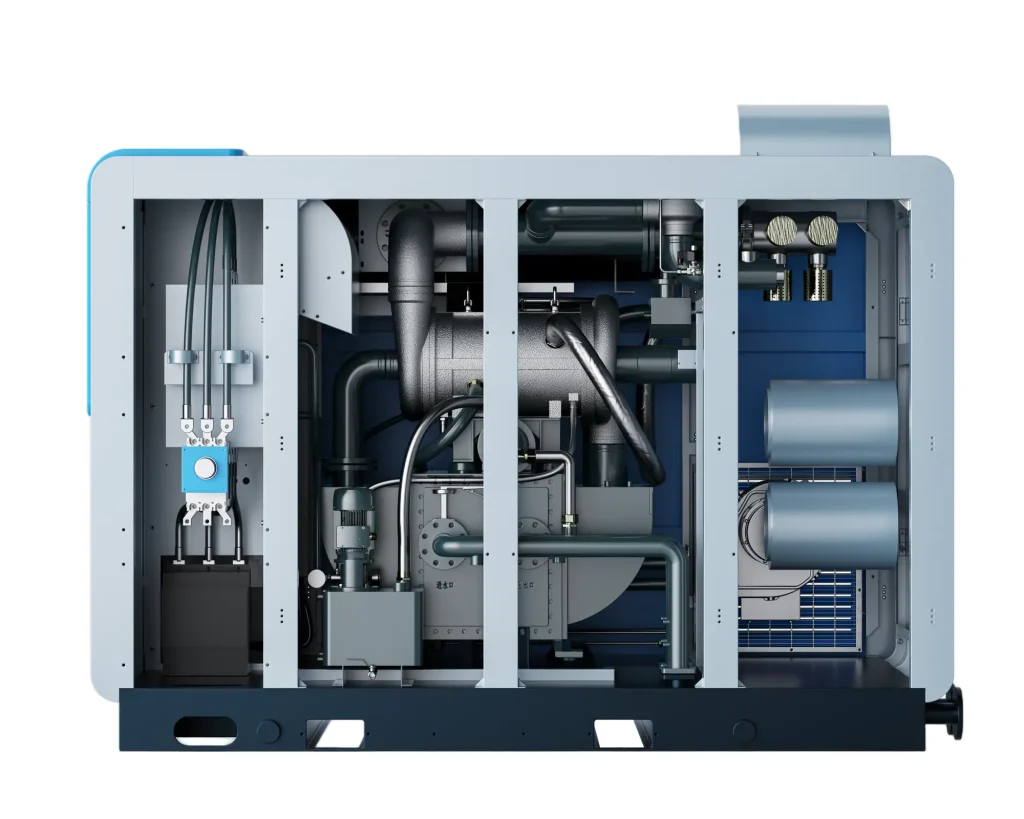

Important Components of Centrifugal Air Compressor

- Impeller: rotating wheel that accelerates the air.

- Diffuser: stationary vanes or ducts that convert velocity into pressure.

- Volute / Casing: collects the compressed air and guides it to the outlet.

- Inlet Guide Vanes (IGV) and other controls: regulate flow entering the impeller for better efficiency.

Advantages & Limitations of Centrifugal Air Compressor

Advantages:

- High flow capability and continuous operation.

- Fewer sliding parts compared to displacement compressors → lower maintenance.

- Typically oil-free air path in many designs → important for clean air applications.

Limitations:

- Less suitable for extremely high pressures in a single stage compared to some displacement types.

- Performance sensitive to flow and inlet conditions (e.g., temperature, pressure) — surge and stability must be managed.

Types of Centrifugal Air Compressors

When discussing centrifugal air compressors, it’s helpful to classify the major types and variations.

a) By Flow Direction / Impeller Style

- Radial (or radial-flow) centrifugal compressors: Air flows in radially from the centre of the impeller and exits at the outer diameter. Better suited for higher pressure rise.

- Axial (or axial-flow) compressors (though strictly speaking a different category) are sometimes grouped for comparison: they push air parallel to the shaft and are optimized for very high flow, low pressure settings.

b) Single-Stage vs Multi-Stage

Many centrifugal air compressors are multi-stage (two, three, or more) to gradually build up pressure while managing temperature, efficiency, and moisture.

c) Oil‐Free vs Oil-Injected

For many industrial applications requiring clean air (food, pharmaceutical, electronics), oil‐free centrifugal air compressors are preferred, meaning the air/gas path remains uncontaminated by lubricating oil.

d) Fixed Speed vs Variable Speed

Modern machines may feature variable speed drives (VSD) to match flow to demand and improve efficiency, though this classification is more about drive/control than compressor type itself.

Applications of Centrifugal Air Compressors

The versatility of centrifugal air compressors allows them to serve in many industrial and commercial settings. Here’s a snapshot of major application areas:

Industrial Manufacturing & Processing

- Clean, oil-free compressed air for pharmaceutical, food & beverage, and electronics manufacturing.

- Process air for chemical plants — e.g., compressing gases for acid plants, petrochemicals.

- Power generation: supplying compressed air or gas to turbines, large machinery, boiler support.

HVAC / Refrigeration / Building Systems

- Large-scale air-conditioning and refrigeration chillers employ centrifugal compressors for high-volume air/gas flow.

Oil & Gas / Pipeline / Natural Gas Transmission

- Compressing natural gas for pipeline transport: increasing pressure to move gas long distances.

- Refineries and petrochemical plants use centrifugal compressors for various gas-handling duties.

Utilities & Large-Scale Facilities

- Water/waste-water treatment, utilities that require large volumes of compressed air or gas for aeration, pneumatic conveying, etc.

Emerging / Specialty Applications

- Clean energy: e.g., hydrogen compression, oxygen/nitrogen separation (air-separation plants) where oil-free, large flow machines are required.

Why choose a centrifugal air compressor for these applications?

Because when your requirement is high flow, steady output pressure, and continuous duty, the centrifugal air compressor often offers lower life-cycle cost, easier maintenance, and better reliability compared to many displacement machines.

Key Considerations for Centrifugal Air Compressor Selection & Operation

When selecting or operating a centrifugal air compressor, keep these important points in mind:

- Flow vs Pressure requirements: Match the compressor to the required flow (volume) and pressure. Too little flow or wrong pressure range will reduce efficiency.

- Inlet conditions: Temperature and pressure at the inlet affect performance and delivered power. The nature of the gas matters.

- Surge & stability control: Dynamic compressors are prone to surge if the flow falls below the stable operating line. Proper controls help.

- Maintenance & reliability: While fewer wearing parts than some displacement types, the high-speed rotors, bearings, seals still require good design and maintenance.

- Oil‐free design vs oil‐flooded: For critical clean air applications, oil-free path is essential. Check design robustness.

- Energy efficiency: Look at full-load and part-load efficiency, as centrifugal machines tend to perform best when properly matched to the system.

Conclusion

The centrifugal air compressor is a powerful and efficient machine for compressing large volumes of air or gas in a continuous flow, moderate to high pressure industrial setting. By leveraging high-speed impellers and diffusers, it converts kinetic energy to pressure, achieving output that is ideal for applications like manufacturing, HVAC/refrigeration, petrochemicals, and utilities.

When you require steady pressure, high flow, oil-free air, and reliable operation, consider a properly sized, maintained centrifugal air compressor. Selecting the right type (radial-flow vs multi-stage vs oil-free), ensuring the inlet conditions and controls are appropriate, will lead to better performance, lower cost of ownership, and longer service life.

For reliable performance and energy-efficient solutions, Seize Centrifugal Air Compressors deliver the quality and innovation trusted by industries worldwide. If you like, I can also prepare a downloadable checklist or infographic for selecting and maintaining a centrifugal air compressor. Would you like that?