Introduction

In modern industry, the purity of compressed air directly impacts product quality and production safety. With surging demand for “oil free contamination” in industries like food, pharmaceuticals, and semiconductors, traditional oil-lubricated compressors have become increasingly obsolete due to oil mist contamination issues. Seize Oil‑Free Screw Air Compressors, leveraging their core advantage of “oil free compression,” have emerged as critical equipment for high-purity air requirements. They serve as the “pure power core” driving upgrades in precision manufacturing and life sciences.

This article systematically analyzes the definition, operating principles, advantages, and applications of oil free centrifugal compressors, providing selection and maintenance guidelines to help practitioners fully understand their value.

What is an Oil Free Centrifugal Compressor?

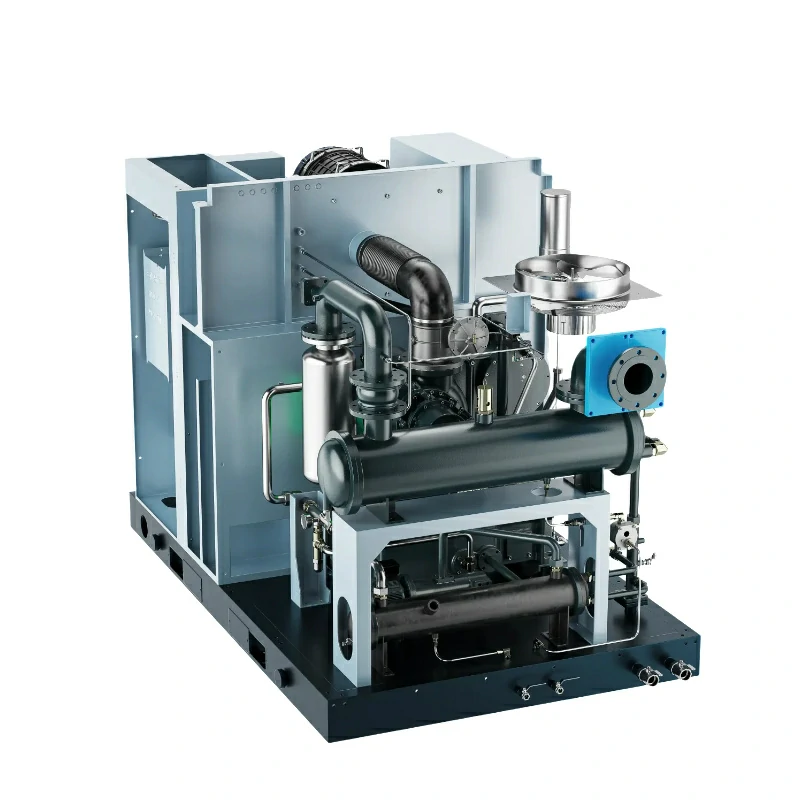

An oil free centrifugal compressor is an industrial device that compresses air using centrifugal force without any lubricating oil throughout the process. Its core logic involves: a high-speed rotating rotor generates centrifugal force, accelerating air toward the periphery. A diffuser then converts this kinetic energy into pressure energy, ultimately delivering oil-free compressed air.

Its compression chamber is completely isolated from the lubrication system. Key components utilize dry gas seals, magnetic seals, or oil-free lubrication materials, eliminating oil contamination at the source. This enables direct output of air meeting very strict purity standards.

Differences Between Oil Free Centrifugal Compressors and Oil-Lubricated Compressors

Traditional oil-lubricated compressors rely on lubricating oil for lubrication and sealing, inevitably introducing oil mist into the air. Even with additional oil removal equipment, complete oil elimination remains challenging. The oil free centrifugal compressor differs in three key aspects:

- Air Purity: Directly outputs oil free air without requiring oil removal processes; traditional models necessitate additional oil removal, still carrying contamination risks.

- Maintenance Logic: No lubrication-related components; maintenance focuses solely on filtration and cooling systems. Traditional models require periodic oil and filter changes, entailing higher costs and more steps.

- Application Scenarios: Specializes in high-purity demand scenarios (e.g., pharmaceuticals, semiconductors). Traditional models suit applications with lower purity requirements (e.g., machining).

Classification and Primary Models of Oil Free Centrifugal Compressors for Industrial Applications

Classified by output pressure into three categories to suit different needs:

- Low-pressure models: 0.3-0.7MPa, used for food baking/mixing and medical ventilator air supply. Compact size, low energy consumption.

- Medium-pressure models: 0.7-1.5MPa, most widely applied. Covers sterile food filling, pharmaceutical API synthesis, and electronic PCB cleaning. Balances pressure and flow.

- High-pressure models: Pressure >1.5MPa, used for semiconductor wafer etching and pharmaceutical specialty gas delivery. These require higher precision rotors and advanced sealing technology, often employing multi-stage compression.

Working Principle of Oil Free Centrifugal Compressors

Basic Structural Components

- Impeller: Constructed from high-strength material, rotates at high speeds (10,000–30,000 rpm) to generate centrifugal force.

- Diffuser: A ring-shaped structure with fixed blades. By enlarging the flow channel cross-section, it reduces gas velocity, converting kinetic energy into pressure energy.

- Air Inlet and Outlet: The inlet connects to a high‑efficiency filter to prevent impurities; the outlet connects to a cooler and pressure stabilizer to ensure stable output.

Auxiliary parts include variable-frequency drives, cooling systems, and control systems to ensure stable operation.

Detailed Workflow

- Air Intake: Ambient air enters through a fine filter, preventing dust and impurities from entering.

- Acceleration and Centrifugal Compression: Air is accelerated outward by the high-speed rotor; in the diffuser, its kinetic energy is converted to pressure. In multi-stage compressors, this process repeats until the required pressure is reached.

- Air Discharge: The compressed air exits through the outlet, cooled by the cooling system, and stabilized by a pressure regulator before being delivered to downstream systems.

How Oil Free Design Ensures Air Purity in Oil Free Centrifugal Compressors

- Sealing Isolation: Using dry gas seals or magnetic seals prevents lubricant from entering the compression chamber.

- Oil‑Free Lubricated Components: Bearings and other parts use self-lubricating materials (e.g., ceramics, PTFE) or non-oil lubrication, eliminating oil contact entirely.

Common Technical Features

- Multi-stage Compression: Reduces per-stage pressure ratio, improving efficiency and reducing heat generation.

- Variable-Frequency Speed Control: Adjusts rotational speed to match air demand, improving energy efficiency.

- High‑Efficiency Cooling: Uses advanced cooling systems (e.g., air-water hybrid) with sensors to dynamically regulate.

Key Advantages of Oil Free Centrifugal Compressors for Industry

- High-Purity Air: Produces absolutely oil-free air, which is critical in industries like pharmaceuticals and semiconductors.

- Energy Efficiency: Centrifugal design and variable-frequency control reduce energy consumption.

- Low Maintenance: Without oil-related components, maintenance is simplified, focusing on filters and cooling systems.

- Long Service Life: High-quality materials and oil-free design minimize wear and contamination, extending lifespan.

- Environmentally Friendly: No lubricant leakage; energy-efficient operation reduces carbon footprint.

Application Industries and Scenarios for Oil Free Centrifugal Compressors

- Food & Beverage: For pneumatic mixers, aseptic filling, and clean conveying lines.

- Pharmaceutical: In sterile production, API synthesis, and clean packaging.

- Semiconductor / Electronics: High‑purity air needed for wafer etching, PCB production, and clean-room processes.

- Medical & Laboratory: For ventilators, mass spectrometry, sterile workstations, etc.

- Chemical & High-Demand Sectors: Fine chemicals, specialty gas delivery, and corrosion-resistant systems.

Selection & Maintenance Guide for Oil Free Centrifugal Compressors

Selecting the Right Oil Free Centrifugal Compressor

- Determine required pressure and flow rate based on your process.

- Consider your operating environment (temperature, humidity, contamination).

- Budget: oil-free compressors often have higher upfront cost, but long-term savings.

Daily Maintenance Tips for Oil Free Centrifugal Compressors

- Regular inspections: check pressure stability, bearings temperature, filter condition.

- Filter & Cooling Maintenance: clean/replace intake filters periodically; monitor cooling medium.

- Troubleshooting: identify issues like abnormal noise, overheating, or leakage early and escalate to service when needed.

Frequently Asked Questions

- Which industries benefit most from oil-free compressors? Sensitive industries like food, pharma, electronics, labs.

- Are oil-free compressors more expensive? Yes, upfront, but saved maintenance and energy costs often justify.

- Can they run continuously? Yes — many oil-free machines are designed for 24/7 operation with minimal downtime.

- Installation Notes? Ensure proper foundation, access space, clean intake, and safety protocols.

Summary

Oil-free centrifugal compressors represent a highly pure, efficient, and low-maintenance solution for industries with critical air quality demands. While Seize’s product lineup is strong in screw compressors (e.g., Dry Oil‑Free Screw Air Compressor, SPVC Oil‑Free Screw Blower), they may also offer or plan centrifugal / high‑purity solutions as part of their broader energy-efficient compressor portfolio. For tailored high-purity air solutions, contact Seize to explore how their products can meet your needs.