1. Introduction to Industrial Compressors

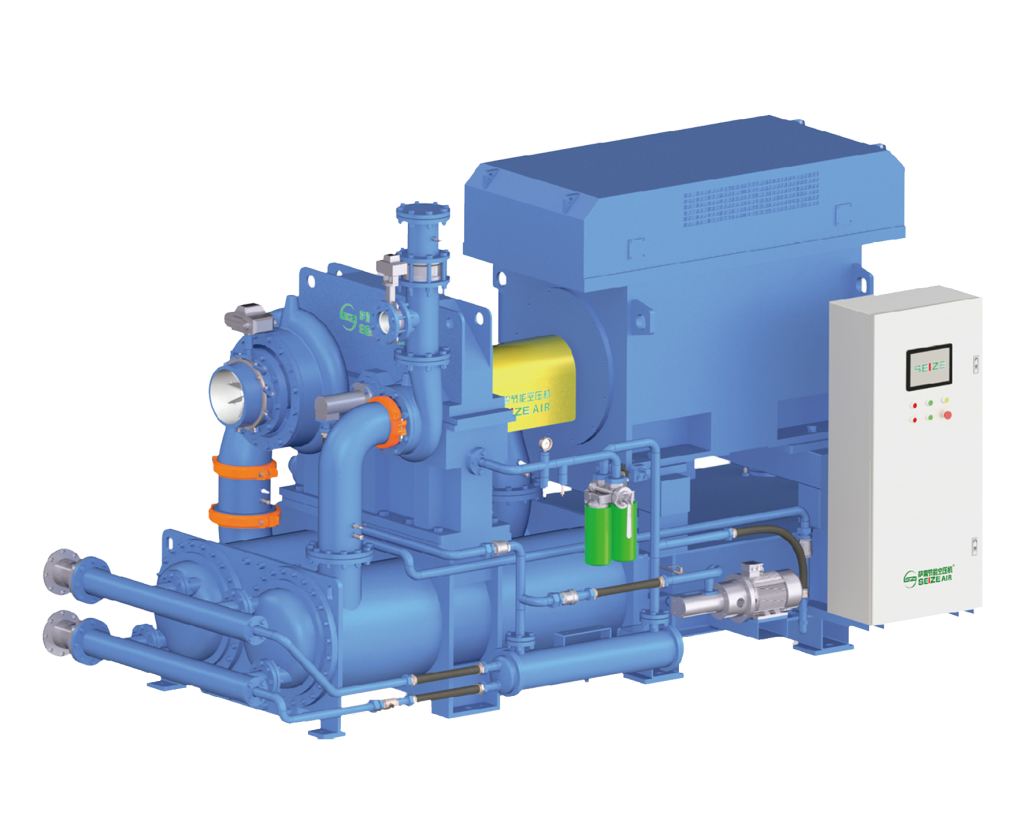

In today’s industrial landscape, industrial air compressors are essential across a range of applications—from manufacturing to energy generation. Among the most common technologies are the centrifugal compressor and reciprocating compressor, each with unique strengths. At Seize Air, we specialize in both, delivering Seize Air compressor solutions that combine performance, efficiency, and tailored design.

2. What is a Centrifugal Compressor?

A centrifugal compressor is a dynamic machine that uses a rotating impeller to add velocity and pressure to air or gas.

➤ Applications

- Chemical processing plants

- HVAC systems

- Power generation facilities

➤ Advantages

- High-efficiency compressors ideal for continuous, high-volume operations

- Low maintenance due to fewer moving parts

- Compact footprint and quiet operation

➤ Limitations

- Higher initial investment

- Less effective in low-capacity or variable-load environments

3. What is a Reciprocating Compressor?

A reciprocating compressor relies on pistons and cylinders to compress air through positive displacement.

➤ Applications

- Oil and gas industries

- Cold storage and refrigeration

- Small and medium-sized workshops

➤ Advantages

- High pressure output—excellent for intermittent usage

- Lower upfront costs, great for smaller-scale operations

- Versatile in mobile or remote setups

➤ Limitations

- Greater vibration and noise

- Requires regular maintenance and part replacements

4. Centrifugal vs Reciprocating: Key Comparison

| Feature | Centrifugal Compressor | Reciprocating Compressor |

|---|---|---|

| Efficiency | Superior in continuous, high-volume flow | Better for fluctuating loads |

| Maintenance | Minimal; longer service intervals | Frequent checks and servicing |

| Cost | Higher upfront, lower long-term costs | Affordable initially, higher lifecycle cost |

| Best Fit | Large-scale, energy-intensive facilities | Small-scale, intermittent-use industries |

Understanding the operational context is key. For example, a centrifugal compressor is optimal for a power plant, whereas a reciprocating compressor fits perfectly in a small assembly line.

5. Why Choose Seize Air Compressors?

At Seize Air, we combine engineering excellence with deep industry insight to deliver unmatched air compression performance.

- 🛠 Innovation: Cutting-edge design for both centrifugal and reciprocating compressors

- ✅ Reliability: ISO-certified production and rigorous testing protocols

- ⚙️ Customization: Custom compressor design tailored to your system and environment

- 🌍 Sustainability: High-efficiency compressors reduce energy use and carbon footprint

- 📞 Support: 24/7 global service and spare parts availability

Whether you’re scaling operations or upgrading systems, Seize Air provides industrial air compressor solutions that fit your exact requirements.

6. Conclusion: Optimize Your Operations with Seize Air

Both centrifugal compressors and reciprocating compressors have distinct benefits, and the right choice depends on your operational needs. By partnering with Seize Air, you gain access to Seize Air compressor solutions that are efficient, reliable, and fully customized.

📩 Contact us today to discover the ideal custom compressor design for your business—boost performance, cut costs, and power your future with Seize Air.