Introduction

Magnetic bearing compressors are increasingly adopted in industrial applications that demand oil-free air, low energy consumption, and continuous operation. However, conventional compressors remain widely used due to their lower upfront cost. Understanding the real differences between these two technologies is essential for long-term performance and cost control.

What Is a Magnetic Bearing Compressor?

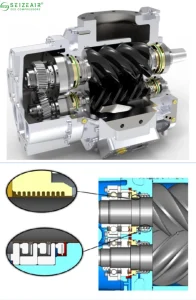

A magnetic bearing compressor uses active magnetic bearings to levitate the rotating shaft, eliminating physical contact between moving parts. Unlike conventional compressors that rely on mechanical bearings and lubrication oil, magnetic bearing systems operate without friction in the bearing assembly.

From an operational perspective, this fundamentally changes how the compressor behaves over time:

- No bearing wear caused by contact

- No lubrication oil required for the bearing system

- Extremely low mechanical loss

- Stable operation under high-speed rotation

Because of these characteristics, magnetic bearing compressor technology is often positioned as a long-term solution for continuous-duty industrial environments.

How Conventional Compressors Work

Conventional compressors—whether piston, rotary screw, or centrifugal—use mechanical bearings and lubrication systems to support the rotating components.

These systems have been proven for decades and are still dominant in many industries. However, their limitations become more apparent in applications that require:

- 24/7 continuous operation

- Strict air purity standards

- Minimal maintenance interruptions

In a conventional compressor, bearings inevitably experience wear, oil degrades over time, and friction losses accumulate. These factors directly influence efficiency, maintenance frequency, and operating cost.

Core Performance Differences Between Magnetic Bearing and Conventional Compressors

| Feature | Magnetic Bearing Compressor | Conventional Compressor | Impact on Long-Term Use |

|---|---|---|---|

| Bearing system | Magnetic levitation | Mechanical bearing | Wear vs no wear |

| Maintenance frequency | Very low | Regular | Downtime risk |

| Energy efficiency | High | Medium | Operating cost |

Mechanical Friction and Energy Efficiency

The most significant performance difference lies in friction.

- Magnetic bearing compressors eliminate bearing friction entirely during normal operation.

- Conventional compressors continuously lose energy due to mechanical contact and oil shear.

As a result, magnetic bearing compressors typically achieve higher energy efficiency, especially under partial load and variable operating conditions.

This advantage becomes more pronounced in large-scale industrial facilities where compressors run continuously and electricity cost is a major operational expense.

Operating Speed and Load Flexibility

Magnetic bearing compressors can operate at very high rotational speeds with precise electronic control. This allows:

- Rapid response to demand changes

- Stable pressure control

- Improved efficiency across a wide load range

Conventional compressors, in contrast, are more constrained by mechanical limits and thermal stress at high speeds.

In applications with fluctuating air demand, magnetic bearing systems maintain efficiency where conventional systems often struggle.

Maintenance Requirements: A Practical Comparison

Maintenance Profile of Magnetic Bearing Compressors

A magnetic bearing compressor has fewer wear components in the bearing system, which directly reduces routine maintenance tasks.

Typical maintenance characteristics include:

- No oil changes for bearing lubrication

- Fewer mechanical failures related to wear

- Predictive monitoring integrated into the control system

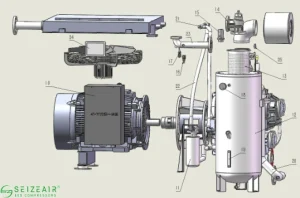

Some industrial manufacturers, including Seize, apply magnetic bearing technology specifically to reduce long-term maintenance risks in continuous-operation compressors.

Maintenance Profile of Conventional Compressors

Conventional compressors require:

- Regular oil replacement

- Bearing inspections and replacements

- Filter and separator maintenance

- Scheduled downtime for servicing

While these tasks are manageable, they accumulate over time—especially in facilities running compressors non-stop.

For plants where downtime directly impacts production output, this maintenance burden becomes a critical consideration.

Cost Comparison: Initial Investment vs Total Cost of Ownership

Initial Purchase Cost

- Magnetic bearing compressors: Higher upfront investment due to advanced technology and control systems

- Conventional compressors: Lower initial cost, widely available across brands and configurations

This cost difference is often the primary reason conventional compressors remain popular.

Long-Term Operating Cost

When evaluating cost realistically, total cost of ownership (TCO) is far more important than purchase price.

Factors affecting TCO include:

- Energy consumption

- Maintenance labor and spare parts

- Downtime-related production loss

- Compressor lifespan

In long-running industrial environments, magnetic bearing compressors frequently achieve lower TCO over 5–10 years, despite higher initial cost.

This is why some manufacturers—such as Seize, when designing compressors for continuous industrial duty—position magnetic bearing systems as long-term cost-control solutions rather than short-term savings.

Noise, Vibration, and Workplace Environment

Noise Characteristics

Magnetic bearing compressors operate with minimal mechanical contact, which significantly reduces vibration and noise.

This makes them suitable for:

- Laboratories

- Clean rooms

- Medical facilities

- Noise-sensitive manufacturing environments

Conventional compressors, even with sound enclosures, typically generate higher vibration levels due to mechanical bearing contact.

Impact on Equipment and Infrastructure

Lower vibration not only improves workplace comfort but also:

- Reduces stress on foundations

- Extends the lifespan of connected piping

- Improves reliability of nearby sensitive equipment

This indirect benefit is often overlooked in basic cost comparisons.

Real-World Application Case

Case Overview

- Industry: Precision manufacturing

- Operating Mode: 24/7 continuous air demand

- Challenge: Rising maintenance costs and energy consumption

Solution

The facility replaced aging conventional compressors with magnetic bearing compressors featuring:

- Oil-free operation

- Variable-speed control

- Integrated condition monitoring

Result

- Energy consumption reduced significantly

- Maintenance intervals extended

- Improved air quality for sensitive production processes

In similar scenarios, compressor solutions aligned with designs offered by Seize have been adopted to balance performance, efficiency, and long-term reliability.

When Conventional Compressors Still Make Sense

Despite their advantages, magnetic bearing compressors are not always the optimal choice.

Conventional compressors may still be suitable when:

- Operating hours are limited

- Budget constraints are strict

- Air demand is relatively stable

- Maintenance downtime is acceptable

For small workshops or intermittent-use applications, the ROI of magnetic bearing technology may not justify the initial investment.

How to Choose Between Magnetic Bearing and Conventional Compressors

When deciding, evaluate the following questions:

- How many hours per year will the compressor operate?

- Is air purity critical for the application?

- What is the cost of downtime?

- How volatile is air demand?

- Are energy costs a major concern?

If continuous operation, efficiency, and low maintenance are priorities, magnetic bearing compressors generally provide superior long-term value.

Conclusion

Magnetic bearing compressors and conventional compressors serve different operational priorities. Evaluating long-term performance, maintenance demands, and total cost of ownership is essential to making the right choice.