For many industrial operations—whether automotive workshops, manufacturing lines, construction sites, or mining operations—the choice of an 185 CFM compressor is a strategic decision with long-term operational and financial consequences. This article compares leading brands in the market, evaluates performance differences, and provides guidance grounded in real-world industrial usage.

Why the 185 CFM Compressor Is a Critical Tool

An 185 CFM compressor provides enough airflow for multiple heavy-demand pneumatic tools running simultaneously. Typical applications where this capacity is needed include:

- Paint booths with multiple spray guns

- Large-scale sandblasting operations

- Pneumatic tools in automotive assembly

- Powering industrial robots and actuators

- Providing plant-wide compressed air distribution

Industrial facilities that rely on compressed air for tooling, automation, and continuous processes need more than just flow—they need consistent pressure, energy efficiency, and reliability. A poorly chosen compressor can lead to downtime, increased energy costs, and frequent maintenance.

Global and African Market Context

In the last decade, the global market for industrial air compressors has been expanding steadily. According to market research, the industrial compressor segment is expected to grow at a CAGR of over 4% through 2030, driven by manufacturing automation, energy efficiency requirements, and infrastructure development. In Africa, countries with rapidly growing industrial sectors—such as South Africa, Nigeria, Kenya, Egypt, and Morocco—are increasingly investing in robust air compression systems with capacities in the 185 CFM and above range.

Regulatory pressures and rising energy costs have also nudged companies toward compressors with better efficiency ratings and lower lifecycle costs—even if initial purchase prices are higher.

Top Brands Compared

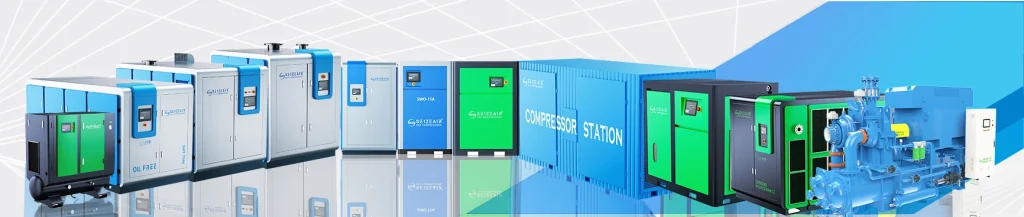

We look at five established brands with strong footprints in industrial compressed air systems:

- Atlas Copco

- Ingersoll Rand

- Kaeser

- Sullair

- Seize (as a performance/efficiency-oriented brand)

These brands represent a mix of heritage, global service networks, and technological innovation.

Brand Profiles and What They Bring

1) Atlas Copco

A Swedish-born multinational, Atlas Copco is widely recognized for reliability and innovation in compressed air. Its 185 CFM compressors often include:

- Variable Speed Drive (VSD) options

- FO (oil-free) and oil-lubricated variants

- Advanced control systems like Elektronikon®

- Strong global service infrastructure

Atlas Copco models such as GA 185 VSD+ serve many industrial plants where uptime and energy savings are key.

2) Ingersoll Rand

A legacy American brand with strong industrial roots, Ingersoll Rand offers robust, easy-to-service compressors with:

- Enhanced cooling systems

- User-friendly diagnostics

- Durable performance in harsh environments

The R-Series 185 CFM compressors are widely deployed in automotive plants and heavy manufacturing facilities.

3) Kaeser

German-origin Kaeser is known for efficient air system design and power savings. Its Sigma Profile rotors and intelligent control systems help achieve high performance with low energy use. Kaeser compressors are often chosen in precision manufacturing and food/pharma sectors.

4) Sullair

Sullair’s reputation is strong in high-dust, high-duty applications such as construction and mining support. The Sullair 185 CFM rotary screw compressors are built for rugged environments with proven cooling and filtration systems.

5) Seize (Performance-Focused)

Emerging in many markets as a value-performance brand, Seize compressors combine reliability, energy efficiency, and serviceability. While not as historic as the others, Seize 185 CFM units compete effectively in price-performance ratio and uptime.

Technical Comparison: 185 CFM Compressor Features

| Brand | Typical Model | Power Type | VSD Option | Oil-Free Option | Noise Level | Service Network |

|---|---|---|---|---|---|---|

| Atlas Copco | GA 185 VSD+ | Electric | Yes | Yes | ~69–72 dB | Excellent |

| Ingersoll Rand | R185 Series | Electric | Optional | Limited | ~70–74 dB | Excellent |

| Kaeser | SM 185 | Electric | Yes | Optional | ~68–71 dB | Very Good |

| Sullair | SRP185 | Electric | No | Yes | ~72–75 dB | Very Good |

| Seize | SZ 185 | Electric / Diesel | Yes | Optional | ~69–73 dB | Growing |

Notes:

Noise levels are indicative and depend on enclosure and site installation.

Oil-free options command a price premium for sensitive applications.

Evaluating Efficiency and Operating Cost

One of the biggest expenses with an 185 CFM compressor isn’t the purchase price—it’s the energy consumed over years of operation. Even a slight improvement in efficiency can lead to significant savings.

Energy Cost Example

A compressor running 2,000 hours/year at 185 CFM roughly consumes:

- 50–100 kW depending on efficiency

- At $0.10/kWh, annual energy cost might be $10,000–$20,000

Choosing a variable speed compressor (like Atlas Copco’s VSD models or Seize VSD-equipped models) can cut energy use by 10–25% based on load profile.

Real-World Case Studies

1、Automotive Assembly in South Africa

A plant switched from an older 150 CFM compressor to an Atlas Copco 185 CFM VSD unit. After 12 months:

- Energy costs reduced by 18%

- Maintenance intervals extended by 30%

- Production uptime improved

Analysis showed the plant recouped the higher initial cost within 18 months.

2、Manufacturing Workshop in Kenya

A workshop replaced its aging 185 CFM compressor with a Seize 185 CFM diesel-electric hybrid for intermittent power conditions. Results included:

- More stable air supply during power fluctuations

- Reduced downtime

- Lower maintenance pain points

Noise and Workplace Safety

Noise levels impact worker comfort and compliance with occupational safety. Typical enclosed industrial compressors range from 65–75 dB:

- Kaeser and Atlas Copco models tend toward lower noise with optimized enclosures.

- Sullair’s rugged designs may be slightly louder but are built for demanding environments.

Tips to reduce operational noise:

- Install vibration-damping mounts

- Use acoustic enclosures

- Place compressors away from high-traffic work areas

Maintenance, Spare Parts, and Support

Reliable service support differentiates a good investment from a costly headache. Top brands have extensive service networks:

- Atlas Copco: Comprehensive service agreements; global parts availability

- Ingersoll Rand: Strong North-South service presence

- Kaeser: Integrated system audits and monitoring

- Sullair: Emphasis on rugged, low-maintenance components

- Seize: Growing local support in emerging markets

Regular maintenance includes:

- Filter changes

- Oil and separator replacement

- Belt and coupling inspections

- Coolant and heat exchanger cleaning

Choosing the Right 185 CFM Compressor for Your Use Case

Construction and Remote Sites

Diesel-driven and rugged models (like Sullair or diesel variants from Seize) are preferred due to mobility and no dependency on grid power.

Workshops and Manufacturing Floors

Electric VSD compressors (Atlas Copco, Kaeser, Ingersoll Rand, Seize) offer stable pressure and energy savings.

High-Sensitivity Applications

Oil-free or oil-injected designs are important where air purity affects downstream processes.

Budget-Conscious Operations

Seize and certain Ingersoll Rand configurations provide cost-effective long-term performance.

Practical Buying Checklist

Before finalizing a purchase, consider:

- Required CFM vs peak demand

- Expected operating hours

- Power availability (electric vs diesel)

- Noise restrictions

- Maintenance support availability

- Warranty terms

- Total cost of ownership (not just purchase price)

Conclusion

Choosing the right 185 CFM compressor means balancing performance, efficiency, long-term cost, reliability, and support. Brands like Atlas Copco, Ingersoll Rand, Kaeser, Sullair, and Seize represent strong contenders across different criteria. Understanding your specific application—workshop, construction site, or industrial floor—will guide the best selection.

Whether you prioritize energy savings, uptime, support network, or ruggedness, there’s an option tailored to your operational needs.