Investing in a 150 hp air compressor is rarely about replacing equipment—it is about redefining how compressed air supports production efficiency, cost control, and long-term operational stability.

At this capacity level, compressed air becomes a strategic asset rather than a utility expense. Understanding ROI requires looking far beyond the purchase price.

When a 150 HP Air Compressor Truly Makes Sense

A 150 hp air compressor is typically justified when compressed air demand becomes both continuous and mission-critical.

This often occurs in facilities where:

- Multiple production zones rely on compressed air simultaneously

- Pressure drops directly affect cycle time or product quality

- Existing compressors operate near full load most of the time

Many plants reach this point gradually. What starts as occasional overload turns into constant stress on smaller systems, leading to escalating maintenance costs and unpredictable downtime.

At that stage, ROI is no longer theoretical—it becomes operationally visible.

Energy Consumption: The Core of ROI (and the Biggest Variable)

This is the single most important ROI driver, and also the most misunderstood.

A 150 hp air compressor running 7,000 hours per year can consume hundreds of thousands of kWh annually. Over a 10-year lifecycle, energy costs frequently exceed the initial investment several times over.

What truly defines ROI is not horsepower, but how the compressor behaves under real operating conditions.

Why Partial Load Performance Matters More Than Peak Efficiency

Most industrial systems do not operate at full capacity continuously. Demand fluctuates with:

- shift changes

- production cycles

- seasonal variations

Traditional fixed-speed compressors waste energy whenever demand drops, even slightly. This wasted energy does not appear as a failure—it simply shows up as a higher electricity bill year after year.

Modern 150 hp systems designed with adaptive load control dramatically reduce these hidden losses. In long-term ROI analysis, this difference alone can shorten payback by months or even years.

Fixed-Speed vs Adaptive Systems

This comparison often makes buyers uncomfortable because it challenges familiar purchasing habits.

A fixed-speed 150 hp air compressor may appear simpler and cheaper upfront. However, when analyzed across thousands of operating hours, inefficiencies compound rapidly.

Adaptive or variable systems:

- align output with real demand

- reduce unload losses

- stabilize pressure without overshooting

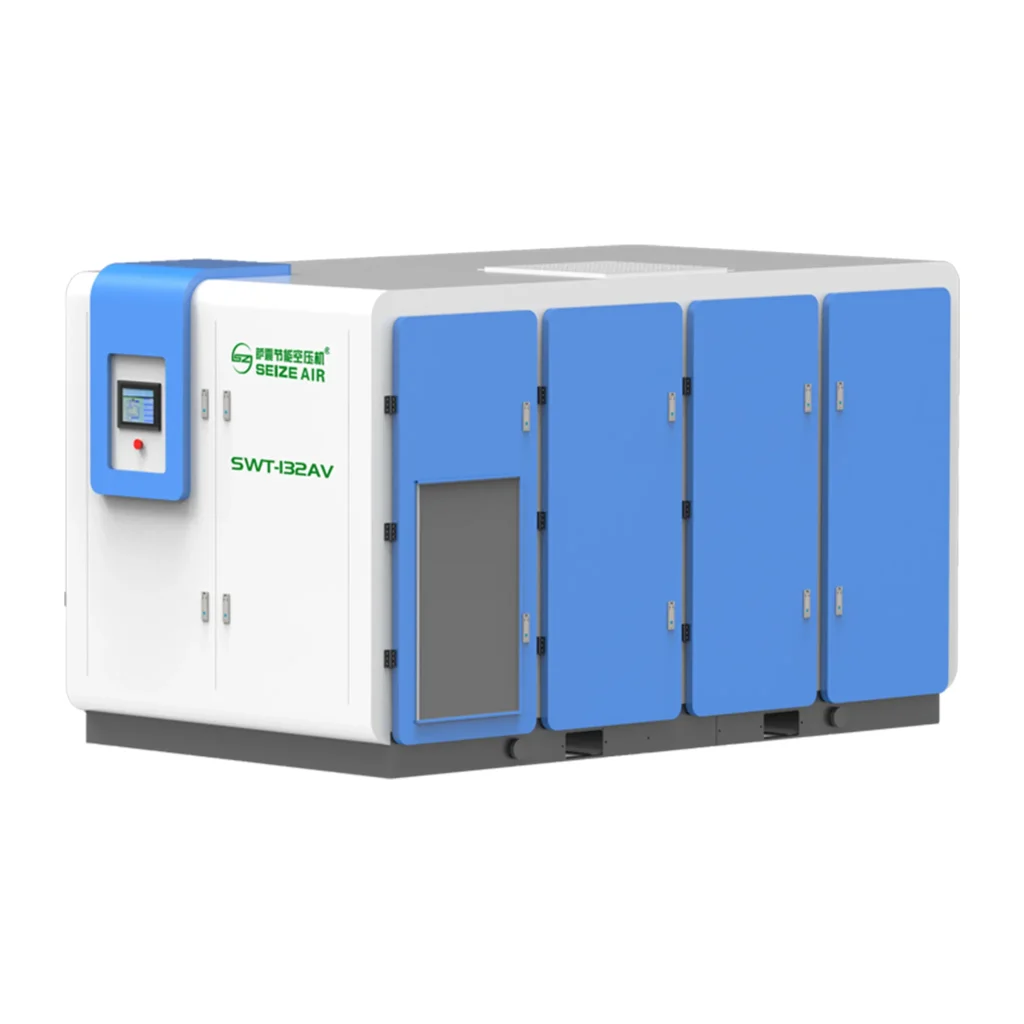

Manufacturers like Seize focus heavily on matching compressor behavior to real industrial usage rather than laboratory conditions—an approach that consistently improves ROI over the system’s lifespan.

Maintenance and Lifecycle Costs

Maintenance costs are rarely decisive on paper—but they are decisive in reality.

In continuous-duty environments, small maintenance inefficiencies escalate into:

- increased downtime frequency

- higher labor intervention

- premature component replacement

A 150 hp air compressor that is difficult to service or sensitive to contamination becomes expensive long before it technically “fails.”

From an ROI standpoint, the most valuable systems are not those that eliminate maintenance, but those that make maintenance predictable, fast, and non-disruptive.

| ROI Factor | Conventional System | Optimized 150 HP System |

|---|---|---|

| Part-load efficiency | Low | High |

| Pressure stability | Variable | Stable |

| Maintenance planning | Reactive | Scheduled |

| Energy cost volatility | High | Controlled |

| Typical ROI horizon | Uncertain | 2.5–4 years |

This table reflects why experienced buyers increasingly evaluate compressors as systems—not standalone machines.

Pressure Stability

Pressure instability rarely appears in ROI spreadsheets, yet it quietly affects profitability.

When pressure fluctuates:

- pneumatic tools lose efficiency

- operators compensate manually

- system pressure is often increased unnecessarily

Raising pressure by even a small margin increases energy consumption disproportionately. Over time, this erodes ROI without triggering alarms or failures.

A well-configured 150 hp air compressor maintains pressure within narrow bands, eliminating the need for these compensations and improving ROI indirectly through consistency.

Centralization vs Fragmentation

Many facilities operate multiple smaller compressors installed over time.

While this seems flexible, fragmentation introduces:

- overlapping inefficiencies

- uneven load distribution

- higher cumulative maintenance risk

Consolidating into a single, well-sized 150 HP system often improves ROI faster than expected. The gains come not from one dramatic improvement, but from the elimination of dozens of small inefficiencies.

Risk Reduction as a Financial Metric

Unplanned downtime, missed delivery deadlines, and quality deviations all carry measurable costs.

A reliable 150 hp air compressor:

- reduces emergency interventions

- stabilizes production schedules

- protects downstream processes

From an ROI perspective, risk reduction is not abstract—it is a form of cost avoidance that compounds over time.

A Realistic ROI Scenario (Industry-Based)

In a typical industrial facility upgrading to a modern 150 HP system:

- energy savings range from 12–20%

- maintenance-related downtime drops noticeably

- pressure-related quality issues decrease

Payback periods commonly fall between 2.5 and 4 years, depending on operating hours and energy pricing.

These figures align with real-world deployments, including projects delivered by Seize, particularly in high-duty industrial environments.

ROI Improvement After Installation: The Overlooked Phase

ROI does not end at commissioning.

Facilities that actively manage:

- air leaks

- demand profiles

- operating pressure

often outperform initial ROI projections. Long-term support and system transparency play a critical role here.

This is where suppliers like Seize differentiate themselves—not through aggressive marketing, but through lifecycle-oriented system design and support.

Common Ways ROI Is Accidentally Destroyed

Not through major mistakes, but through neglect:

- ignoring leak audits

- operating above required pressure

- failing to reassess demand as production evolves

These behaviors flatten ROI curves silently.

Final Perspective

A 150 hp air compressor should be evaluated as infrastructure, not equipment.

When ROI is analyzed through energy behavior, reliability, pressure stability, and lifecycle management, the financial logic becomes clear. The strongest returns come not from short-term savings, but from sustained, controllable performance over many years.