In modern industrial settings, compressed air is an essential utility that powers machinery, controls automation and supports various production processes. It is crucial to select the right type of compressor, as this affects efficiency, maintenance costs, and operational reliability. The two most commonly considered options are centrifugal and reciprocating compressors. Understanding the differences between them can help procurement managers, engineers and distributors to make informed decisions.

Understanding Centrifugal and Reciprocating Compressors

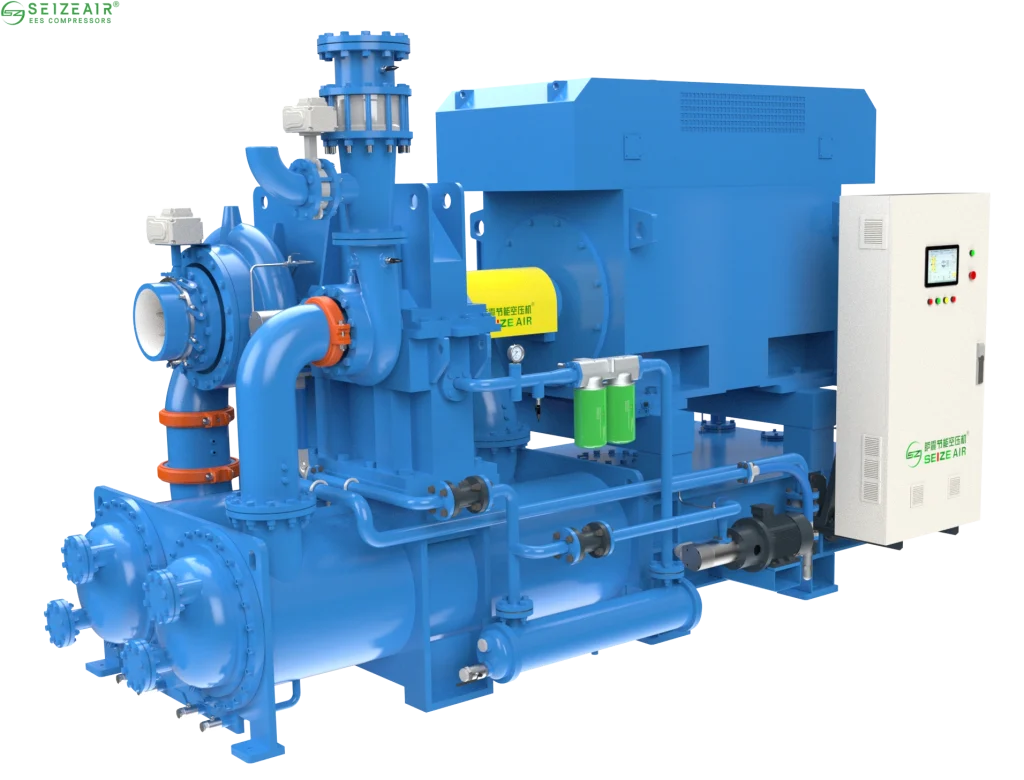

Centrifugal compressors operate using a rotating impeller that accelerates air outwards into a diffuser, converting velocity into pressure. This type is known for its continuous airflow, smooth operation and suitability for high-volume applications.

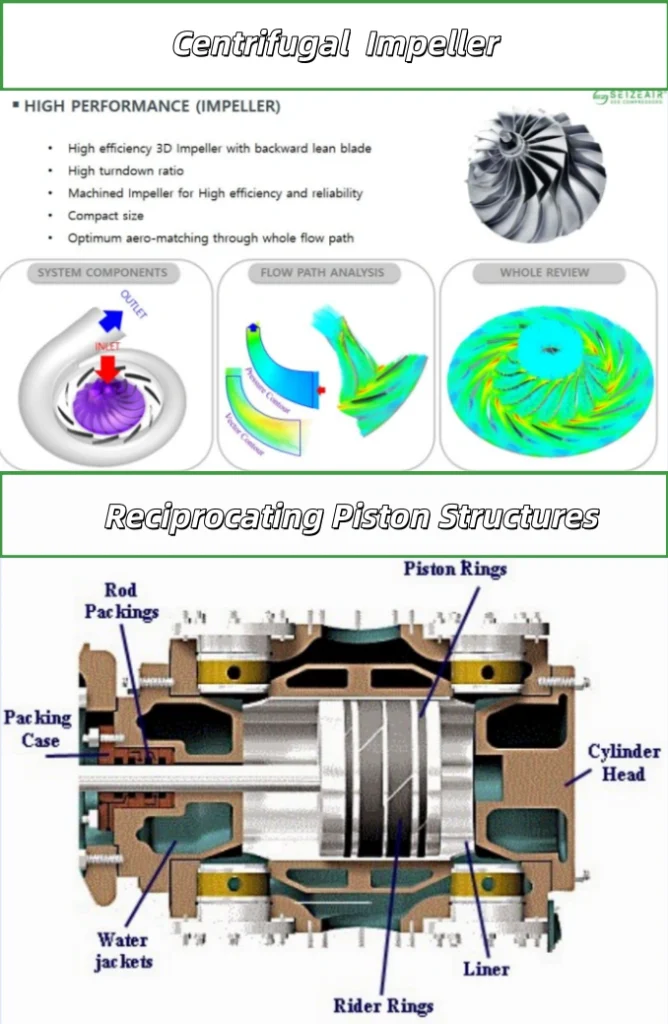

In contrast, reciprocating compressors use pistons driven by a crankshaft to compress air in a cylinder. They are positive displacement compressors, offering high pressure capabilities and a compact design for intermittent or variable-demand operations.

The main differences between centrifugal and reciprocating compressors for industrial use lie in their airflow characteristics, pressure delivery and maintenance requirements. Centrifugal compressors are ideal for large-scale, continuous operations, while reciprocating compressors are favoured for smaller or high-pressure applications.

Performance and Efficiency Comparison

Several factors come into play when comparing the efficiency of centrifugal and reciprocating compressors:

- Energy efficiency: Centrifugal compressors generally offer greater efficiency at high capacities thanks to their continuous airflow and minimal energy loss during operation. Reciprocating compressors can consume more energy, particularly under fluctuating loads, due to the pistons frequently starting and stopping.

- Pressure and flow control: Reciprocating compressors excel in applications requiring high pressure (above 200 psi) and precise delivery, making them suitable for specialised tools and injection moulding operations. While centrifugal compressors are less ideal for extremely high pressure, they maintain a steady airflow over extended periods, which supports process stability in the chemical, pharmaceutical and food production industries.

- Maintenance Considerations: Reciprocating compressors require more frequent maintenance due to wear on pistons, rings and valves. Centrifugal compressors have fewer moving parts and oil-free designs, so they tend to have longer service intervals and lower downtime. This translates to reduced operational costs over time.

Application Scenarios: Matching Compressor Types to Industrial Requirements

The choice between centrifugal and reciprocating compressors depends on the specific industrial requirements:

- High-volume, continuous operations: Centrifugal compressors excel in large-scale production lines, providing a steady airflow that reduces energy fluctuations and ensures consistent quality.

- High-pressure intermittent applications: Reciprocating compressors are better suited to workshops, automotive assembly and industries requiring burst pressure or compact installations.

- Temperature-sensitive processes: Centrifugal compressors tend to produce less heat and vibration than other types of compressor, making them ideal for use in sensitive processes such as electronics manufacturing.

Whether a centrifugal or reciprocating compressor is better for high pressure depends on balancing continuous flow needs with peak pressure requirements. In high-pressure, low-volume scenarios, reciprocating compressors tend to outperform centrifugal units.

Cost and Lifecycle Considerations

When budgeting for a compressor, it is important to consider more than just the initial purchase price. Critical factors include operational efficiency, maintenance and expected lifespan.

- Initial investment: Centrifugal compressors typically require a higher initial investment due to their complex design and larger capacity requirements. Reciprocating compressors are initially more cost-effective for small-scale applications.

- Operating costs: Centrifugal compressors are more energy efficient in large, continuous operations. However, reciprocating units may incur higher running costs if they frequently cycle on and off.

- Longevity and reliability: Centrifugal compressors have fewer moving parts, which leads to a longer lifespan and fewer interruptions. Although reciprocating compressors are durable, they require more regular maintenance and component replacement.

Conclusion

Selecting the right compressor is a strategic decision for industrial operations. Centrifugal compressors are ideal for continuous, high-volume processes, offering energy efficiency, while reciprocating compressors provide high-pressure capabilities and a compact design for intermittent use. Understanding the differences between centrifugal and reciprocating compressors for industrial use, and evaluating their efficiency, enables industries to optimise productivity and reduce long-term costs.

Seize Air offers a range of oil-free screw air compressors designed to meet diverse industrial needs, providing companies seeking reliable, energy-efficient solutions with a viable option. Focusing on durability, efficiency and low maintenance, Seize Air products support consistent production while minimising operational costs.