Introduction

In industrial manufacturing, automotive services, food packaging, and precision electronics, the air compressor is a vital power source. While modern compressors continue to improve in efficiency and reliability, noise remains a persistent challenge. Excessive noise can impact worker comfort, increase health risks, violate environmental regulations, and even affect a facility’s professional image.

As a result, many users search for how to make an air compressor quieter to create a safer, more pleasant working environment. For users of premium equipment like SEIZE AIR energy-saving compressors, effective noise reduction not only benefits employees—it can also extend equipment life, improve energy efficiency, and reduce long-term costs.

Understanding Where Air Compressor Noise Comes From

Before implementing noise-reduction strategies, it’s essential to understand what causes compressor noise. The sound is usually generated by multiple interacting components.

Mechanical Noise from Internal Moving Parts

Inside a compressor, the mechanical system—including rotors, bearings, and gear interfaces—operates at high speed, producing friction, meshing, and structural vibration noise. For example:

- Screw compressors generate a continuous low-frequency hum from rotating rotors.

- Piston compressors create strong, periodic impact noise due to the reciprocating motion.

- Vane compressors may produce constant sliding or friction sound between vanes and rotor.

These noises constitute the baseline mechanical noise for many machines.

Vibration and Structural Resonance Amplify Sound

Often, the real issue is vibration being amplified by the surrounding structure:

- Compressors mounted directly on concrete floors can transmit vibration into the building.

- Rigidly connected pipes can carry pulsation into walls or structural members.

- Stiff mounting feet may cause local resonance under load.

Isolating and decoupling these vibration paths is key to reducing perceived noise.

Airflow Noise from Intake and Discharge

Airflow itself can generate significant noise:

- Turbulence at the intake

- Pulsing at the discharge

- Valve switching noise

- Air hitting pipe walls and creating resonance

These aerodynamic noises can be high-frequency and piercing.

Motor, Fan, and Transmission Noise

The driving motor, its cooling fan, drive belts, and inverters all contribute:

- Fans produce aerodynamic (wind) noise.

- Loose or misaligned belts may flutter or slap.

- Frequency inverters can emit tonal noise at certain switching frequencies.

Models with permanent-magnet variable-speed motors from SEIZE AIR help reduce these noise sources by smoothing startup and adjusting speed to demand.

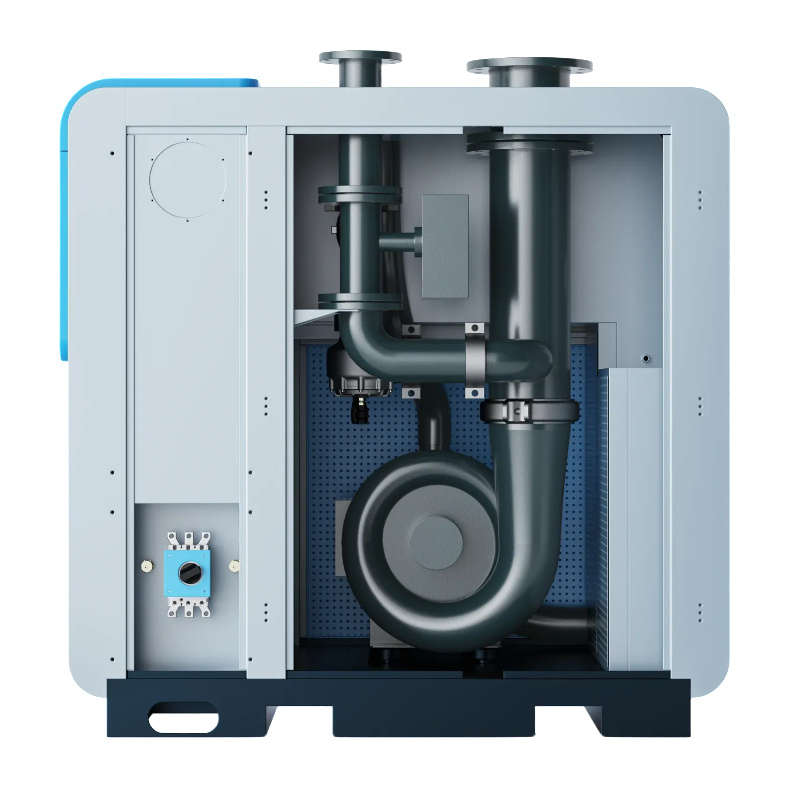

Magnetic-Leviation (Maglev) Centrifugal Compressors: A Naturally Quiet Option

Compressors using magnetic levitation bearings, such as SEIZE AIR’s maglev centrifugal series, offer exceptional quietness:

- Near-zero mechanical contact

- Frictionless rotation

- Extremely low vibration

They are especially suitable for noise-sensitive applications like clean energy, pharmaceuticals, and electronics.

Basic Methods to Make an Air Compressor Quieter

These are practical, low-cost steps that most operations can implement to reduce noise.

Use Anti-Vibration Pads to Absorb Structural Vibration

Installing high-quality vibration pads under the compressor helps isolate it from the floor and building structure. Key tips:

- Select pads rated for your machine’s weight

- Distribute load evenly among all mounting points

- Inspect and replace pads as they age

For screw compressors, this simple fix often reduces felt noise by 10–30%.

Detect and Repair Leaks to Eliminate Hissing Sounds

Compressed air leaks generate sharp “hiss” noises and waste energy. Common leak locations include:

- Pipe joints

- Valves

- Internal fittings

- Cooling lines

- Seals on filters

Perform monthly inspections and track leak points in a maintenance log.

Perform Routine Maintenance to Maintain Quiet Operation

Poorly maintained compressors can become significantly noisier over time. Important maintenance tasks include:

- Checking and changing lubricating oil

- Inspecting bearing wear

- Ensuring belt tension and alignment

- Tightening loose bolts

- Cleaning or replacing clogged filters

- Monitoring head condition and alignment

A well-maintained machine not only runs more quietly—it also lasts longer.

Optimize Compressor Placement to Reduce Noise Reflection

Where you place your compressor has a big impact on perceived noise:

- Avoid positioning it directly in corners or against walls

- Leave clearance around the machine

- Add sound-absorbing panels to nearby walls

- Avoid tight enclosures or resonant cavities

These simple layout changes can naturally reduce noise by 2–5 dB.

Advanced Solutions for Significant Noise Reduction

For facilities that require stringent noise control, consider these more sophisticated strategies.

Install an Intake Silencer

An intake silencer reduces turbulent noise as air enters the compressor. When selecting one, be sure to:

- Keep airflow unrestricted

- Choose a filter material that resists heat and oil

- Clean or replace the silencer regularly

This approach is a very effective part of how to make an air compressor quieter.

Use an Exhaust Muffler to Smooth Discharge Noise

An exhaust muffler helps reduce the pulsation and “jet” sound at the discharge port. Best practices:

- Avoid undersized mufflers that restrict airflow

- Choose durable, heat-resistant materials

- Mount it close to the discharge port for maximum effect

When properly sized, a muffler can cut discharge noise by up to 20%.

Build a Sound-Insulated Enclosure (Soundproof Box)

A tailor-made sound enclosure can dramatically reduce sound levels. A well-designed box should include:

- Double layers for sound absorption and isolation

- Folded or “L-shaped” airflow channels to preserve cooling

- Ventilation or forced cooling (e.g., small fans)

- Access panels for maintenance

A quality enclosure can deliver 6–12 dB of noise reduction, making it ideal for workshops or garages.

Install Acoustic Barriers or Sound Walls

Acoustic panels or sound walls can act as barriers, blocking sound transmission to occupied areas. To maximize effectiveness, pay attention to:

- Wall height

- Sound-transmission class (STC) of the panels

- Placement relative to the compressor and workspace

This is a solid option for larger, open industrial spaces.

Use Flexible Hoses to Decouple Vibration

Rigid metal piping can transmit vibration. Flexible hoses (vibration-isolating connectors) help reduce this. When installing:

- Select hoses rated for your operating temperature

- Avoid over-tightening them

- Use enough length to absorb vibration rather than transfer it

This is a cost-effective way to improve your noise environment.

Industrial-Level Noise Reduction Strategies

For larger facilities, a more systemic, engineering-based approach often delivers the best results.

Design a Dedicated Compressor Room

One of the most effective strategies for reducing sound in production areas is to house the compressor in a separate room. Key design considerations:

- Build with double-layered walls or thick masonry

- Use acoustic doors and windows with proper sealing

- Provide silenced ventilation with folded ductwork

- Implement anti-vibration flooring

- Ensure there is sufficient space for maintenance around each unit

A properly designed compressor room can reduce noise levels by 15–30 dB, making a huge difference in work environment quality.

Relocate the Compressor with Extended Piping

Mounting the compressor away from the work zone and using longer, well-designed piping is a common industrial solution. Important considerations:

- Use larger diameter piping to reduce pressure drop

- Include condensate drains in the design

- Insulate the piping to reduce noise and heat loss

This layout is frequently used in assembly lines, food processing, and other high-demand industrial scenarios.

Select Low-Noise Compressor Models from the Source

Sometimes, the most effective noise control comes from choosing inherently quiet equipment:

- Permanent-Magnet Variable-Speed Screw Compressors: These models (such as SEIZE AIR’s PM VSD screw compressors) benefit from smooth speed control, stable operation, and lower mechanical noise.

- Magnetic-Levitation Centrifugal Compressors: Compressors with magnetic bearings provide ultra-low mechanical vibration and noise.

- Variable-Speed Drive (VSD) Systems: VSD units adjust speed to demand, avoiding unnecessary high-speed operation and reducing both noise and energy consumption.

By selecting the right compressor, you address the source of noise rather than just masking it.

Common Mistakes and Safety Considerations When Reducing Compressor Noise

Avoid Sealing Enclosures Too Tightly

Completely sealing a compressor in an airtight enclosure risks overheating. Without adequate airflow, you may see:

- High running temperatures

- Oil overheating

- Motor alarms

- Reduced lifespan

Good soundproofing design means silence, not suffocation.

Use Quality Vibration Pads

Cheap or undersized vibration pads may compress excessively or fail to isolate vibration. To achieve real improvement, use industrial-grade vibration isolation materials.

Select Proper Flexible Hoses

Using the wrong type of hose may lead to resonance or vibration under pressure. Always match hose specifications to working pressure, temperature, and vibration characteristics.

Don’t Neglect Maintenance

Even the best noise-reduction solution won’t last without proper care. Issues like bearing wear, loose bolts, aging filters, and deteriorating oil can all increase noise over time. A regular, proactive maintenance schedule is critical.

Noise-Reduction Solutions for Different Operating Scenarios

Home or Garage Use

- Anti-vibration pads

- Small soundproof enclosure

- Basic exhaust muffler

This setup is ideal for DIY users or small workshops.

Workshop or Small Industrial Space

- Acoustic barriers or sound walls

- Flexible piping

- Intake silencers

- Smart placement of the compressor

This combination is practical and efficient.

Large Factories or Automated Production Lines

- Dedicated compressor room

- Remote installation with long pipe runs

- Variable-speed or maglev compressors

- Comprehensive, scheduled maintenance plan

This setup is best suited for industrial facilities requiring consistent, low-noise operation.

Conclusion

Effectively addressing how to make an air compressor quieter requires a three-pronged approach:

- Optimize at the source – choose low-noise compressor technology.

- Design your system with noise in mind – use isolation, enclosures, and decoupling.

- Commit to regular maintenance – ensure long-term quiet performance.

With a well-planned noise-reduction strategy, SEIZE AIR–based compressed air systems can achieve reliable, silent, efficient, and long-lasting operation without compromising performance.

By combining advanced equipment (like SEIZE AIR’s Permanent-Magnet Variable-Speed Screw Compressors or Magnetic-Levitation Centrifugal Compressors) with thoughtful design and ongoing care, you’ll transform a noisy workspace into a productive, peaceful, and energy-efficient environment.