Introduction

Air compressors are essential for powering tools and equipment in modern manufacturing and workshops. However, facility managers and engineers often struggle to reduce the noise produced by air compressors. Not only can a noisy unit disrupt productivity and create safety risks, it can also violate workplace noise regulations. Fortunately, there are effective methods of achieving a quieter compressor without compromising performance.

Why Air Compressors Are Noisy

The noise produced by an air compressor typically comes from several sources: mechanical vibrations, high-speed airflow and an inefficient enclosure design. Standard compressors often run at higher RPM, which increases noise from gears and bearings. In addition, turbulent airflow through intake and exhaust ducts can amplify sound levels. For many factories, identifying the root causes of noise is the first step in reducing air compressor noise.

Practical Ways to Make Air Compressors Quieter

1. Optimize Compressor Speed and Components

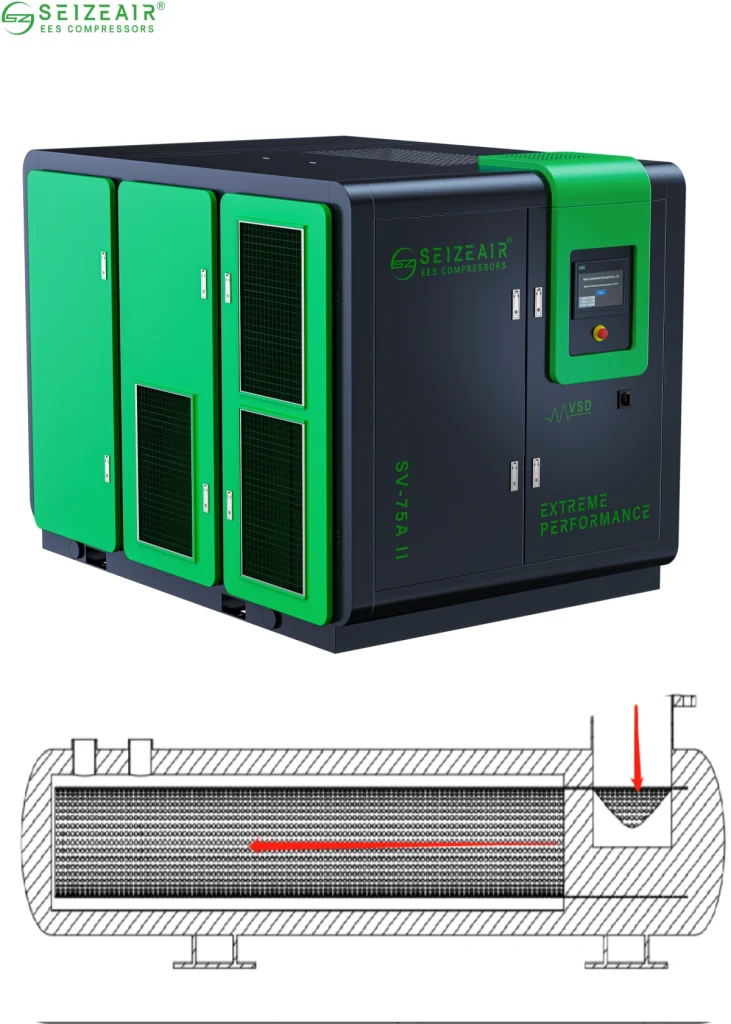

One of the most effective ways to reduce the noise produced by an air compressor is to lower its operating speed. Compressors with larger rotors can achieve the same output at lower RPM, reducing friction and vibration noise. High-precision gears and bearings also play a significant part in minimising noise, as misaligned or worn components generate extra mechanical noise.

2. Use Soundproofing Enclosures

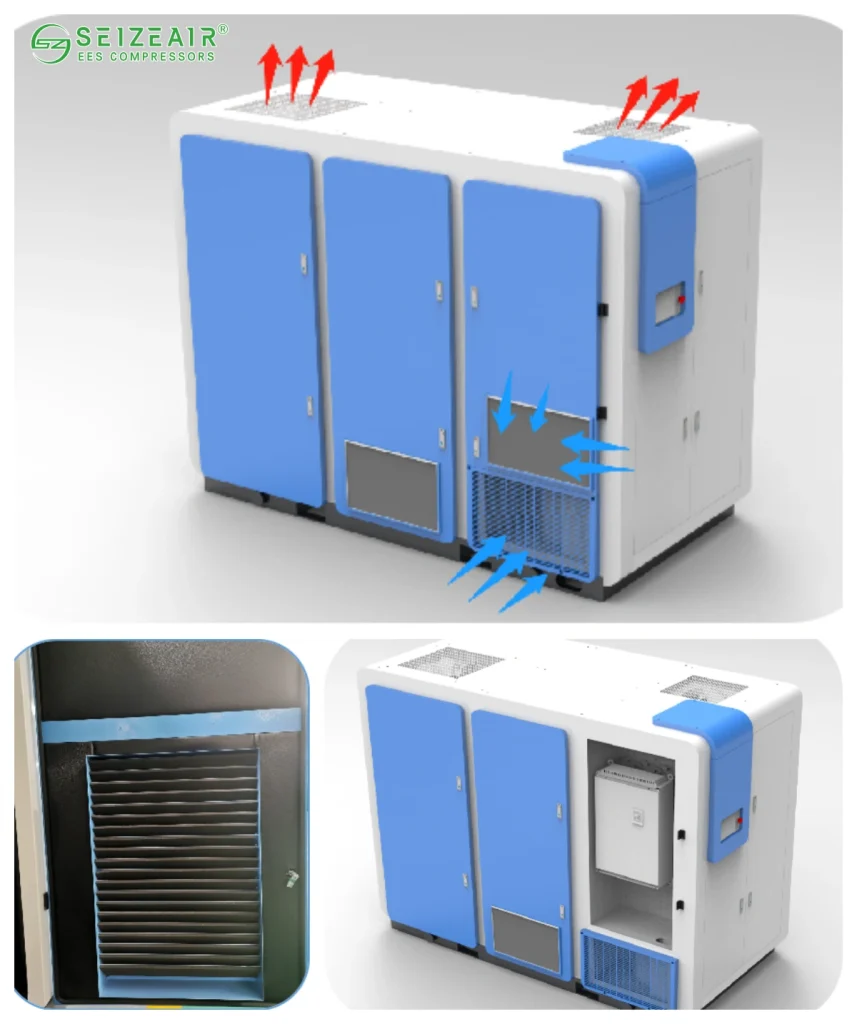

One effective method of reducing air compressor noise is to install a soundproof cabinet or acoustic panels around the compressor. A well-designed enclosure often includes thick (50–60 mm) acoustic foam and tight sealing strips to prevent noise leakage. This design can reduce noise output to levels similar to those in an office, enabling compressors to operate without disturbing nearby workers.

3. Improve Air Intake and Exhaust Design

Noise often escapes through the intake and exhaust systems of the compressor. Using independent ducting can separate airflow paths and block sound propagation. Additionally, compared to axial fans, centrifugal fans produce lower tip-speed noise. Centrifugal designs used in advanced compressors, for example, can reduce fan noise from above 75 dB to as low as 67 dB. Intake silencers and exhaust mufflers with resonance chambers are also effective at reducing the noise of air compressors by dampening high-frequency sounds.

Vibration and Floor Isolation Techniques

Mechanical vibrations are another major contributor to compressor noise. Rubber damping mounts or spring isolators can help to decouple the unit from the floor, thereby reducing the transfer of vibrations into the building structure. Similarly, precision balancing of compressor rotors ensures smoother operation and limits the rattling and low-frequency hum often experienced with older models. For facilities looking to reduce the noise of an air compressor, vibration isolation is a cost-effective and effective solution.

Smart Cooling and Fan Control

Although cooling fans are necessary, they are also a frequent source of noise. Replacing conventional axial fans with centrifugal fans reduces turbulence and lowers overall decibel levels. Additionally, variable-speed fan controls adjust airflow according to real-time operating temperatures. This prevents unnecessary noise generation from constant high-speed operation, offering one of the most effective ways to reduce the noise of an air compressor while also saving energy.

Conclusion

Excessive air compressor noise is more than just an inconvenience; it affects workplace comfort, safety and productivity. Facilities can achieve significant noise reduction by applying strategies such as optimising operating speeds, using soundproof enclosures, improving airflow design, using vibration isolation and installing smart cooling systems.

Companies seeking long-term solutions should consider investing in modern compressor technology. Seize Air, a Chinese manufacturer specialising in reliable, energy-efficient, oil-free screw air compressors, incorporates many of these innovations to provide industrial users worldwide with quieter, cleaner, and more sustainable air solutions.