Introduction

Against the backdrop of global industrial upgrading and the advancement of “dual carbon” goals, compressed air serves as the industrial “power source.” The energy efficiency and reliability of its supply equipment directly impact production efficiency and operational costs. Leveraging unique technological advantages, permanent magnet screw compressors are progressively replacing traditional compressors. They have become core equipment in sectors such as automotive manufacturing, energy extraction, pharmaceutical production, and electronics/semiconductors, providing critical support for continuous and efficient industrial production.

Overview of Permanent Magnet Screw Compressors

Definition of Permanent Magnet Screw Compressors

Permanent magnet screw compressors represent a new generation of compression equipment integrating “permanent magnet synchronous motor technology” with “screw compression technology.” They directly drive the screw rotor assembly via a permanent magnet motor (eliminating traditional couplings), compressing air through rotor meshing. Leveraging the motor’s high magnetic flux density and low-loss characteristics, they achieve dual objectives of “high-efficiency compression + energy-saving operation,” marking the mainstream upgrade direction in industrial compressors.

Core Differences Between Permanent Magnet Screw Compressors and Traditional Models

Compared to traditional variable frequency screw compressors and standard screw compressors, permanent magnet screw compressors differ primarily in “motor technology” and “transmission structure”:

- Motor Type: Traditional models predominantly use asynchronous motors (requiring excitation current), while permanent magnet models employ neodymium iron boron permanent magnet motors (eliminating excitation losses and achieving IE4 ultra-high efficiency standards).

- Drive Method: Conventional models use couplings or belts, incurring transmission losses (approx. 3%-5%). Permanent magnet models typically feature direct “motor-to-host” coupling, achieving near-100% transmission efficiency.

- Energy Efficiency Range: Under equivalent operating conditions, permanent magnet models save 8%-15% energy compared to standard variable-frequency screw compressors and 20%-30% compared to standard fixed-frequency screw compressors.

Global Application Scenarios for Permanent Magnet Screw Compressors

Permanent magnet screw compressors offer broad adaptability across multiple industries, with core applications including:

- Manufacturing: Automotive component processing (pneumatic tool drives, workshop air supply), mechanical equipment manufacturing (CNC machine tool pneumatic fixtures), requiring stable air pressure and low energy consumption.

- Energy Sector: Oil and gas extraction (wellhead air supply), requiring stable air pressure and low energy consumption.

- Manufacturing: Automotive parts processing (pneumatic tool drives, paint shop air supply), machinery manufacturing (CNC machine pneumatic fixtures) requiring stable air pressure and low energy consumption;

- Energy sector: Oil and gas extraction (wellhead pneumatic valve control), photovoltaic power plants (equipment blow-off and dust removal), meeting continuous field operation demands;

- Pharmaceutical Industry: Drug production workshops (oil-free compressed air compliant with GMP standards to prevent oil contamination of pharmaceuticals);

- Electronics Industry: Semiconductor chip manufacturing (clean compressed air supply with low vibration to avoid affecting precision equipment);

- Food Industry: Food packaging (oil-free compressed air contacting food, meeting food safety standards).

Working Principle of Permanent Magnet Screw Compressors

Core Structure Analysis of Permanent Magnet Screw Compressors

The core structure of permanent magnet screw compressors revolves around the “compression host + permanent magnet motor + auxiliary systems,” with each component serving distinct functions:

- Screw Host: The core consists of a pair of meshing screw rotors (typically 5:6 profile), made of high-strength ductile iron (QT500-7). The rotor surfaces undergo hardening treatment (hardness ≥ HRC50) to ensure wear resistance and sealing integrity. Rotor clearance is controlled between 0.01-0.03mm to minimize gas leakage during compression.

- Permanent Magnet Motor: Utilizes neodymium iron boron magnets (high magnetic energy product, excellent temperature stability). The motor housing features a fully enclosed air-cooled design with IP54 or IP55 protection rating, suitable for industrial dusty and humid environments. Wide motor speed range (1500-4500 rpm) allows real-time adjustment based on air demand.

- Auxiliary Systems: Oil-lubricated and oil-free variants available.

- Oil-lubricated systems include oil-air separators (99.9% separation efficiency) and oil coolers (temperature control).

- Oil-free systems utilize dry screws or water lubrication paired with air dryers (dew point reduction).

Detailed Workflow of Permanent Magnet Screw Compressors

The permanent magnet screw compressor operates through a three-step process: “Intake – Compression – Discharge,” fully controlled by permanent magnet motor speed regulation to adapt to dynamic air demand:

- Air Intake Stage: Ambient air passes through the air filter (capturing particles ≥1μm in size) into the intake chamber of the screw compressor. The permanent magnet motor drives the drive rotor, which in turn drives the driven rotor through meshing. The intake chamber volume gradually increases, creating negative pressure to draw in air.

- Compression Stage: The rotors continue rotating, progressively reducing the intake chamber volume as air is compressed into the compression chamber. Simultaneously, the oil-lubricated system injects lubricant into the compression chamber (sealing clearances, cooling air), while oil-free systems utilize rotor profile sealing. The permanent magnet motor adjusts speed via a frequency converter based on pressure demand (e.g., slowing at low pressure, accelerating at high pressure), preventing energy waste from over-capacity operation.

- Compressed Air Output Stage: The compressed air (oil-lubricated or oil-free) enters an oil-air separator (for oil-lubricated models) or a dryer (for oil-free models). After processing, it meets industrial air standards (e.g., oil content ≤3ppm, dew point ≤-40°C). Finally, the pressure is stabilized via a pressure regulating valve before being delivered to the air-consuming equipment. Excess compressed air is vented through a relief valve to ensure system pressure stability.

Technical Features Analysis of Permanent Magnet Screw Compressors

The technical advantages of permanent magnet screw compressors stem from synergistic optimization of construction and control, with core characteristics including:

- High Efficiency, Low Energy Consumption: Permanent magnet motors eliminate excitation losses, achieving 3%-5% higher efficiency than IE3 asynchronous motors. Direct coupling of “motor-host” reduces transmission losses, resulting in 15%-25% greater energy savings compared to traditional models. Simultaneously, variable speed control adapts to 0-100% air load, eliminating no-load energy consumption;

- Stable Pressure Output: Real-time motor speed adjustment via frequency converters controls pressure fluctuations within ±0.02MPa—significantly lower than traditional models’ ±0.05MPa. Consistent air pressure prevents frequent start-stop cycles in pneumatic equipment, extending component lifespan;

- Low noise and vibration: Permanent magnet motors operate smoothly, producing 2-3 dB less noise than asynchronous motors. The screw host features a symmetrical profile design to reduce rotor meshing impact. Combined with vibration-damping pads (e.g., rubber vibration isolators), overall operating noise is controlled at 75-85 dB (measured at 1 meter), with vibration acceleration ≤5 mm/s², improving workshop working conditions.

Key Advantages of Permanent Magnet Screw Compressors

Significant Energy Savings

Energy efficiency is the primary advantage of permanent magnet screw compressors, achieved through dual optimization of “motor efficiency + control methods”:

- Compared to traditional compressors: Under identical conditions of discharge volume (e.g., 10m³/min) and discharge pressure (0.8MPa), the specific power consumption (energy per cubic meter of compressed air) of a permanent magnet screw compressor is approximately 5.2kW・h/m³, while a standard variable frequency screw compressor consumes about 6.0kW・h/m³. while a conventional fixed-frequency screw compressor consumes about 7.0 kW·h/m³. Assuming 8 hours of daily operation over 300 days per year, the permanent magnet model saves approximately (6.0 – 5.2) × 10 × 8 × 300 × 0.8 yuan (electricity cost) = 15,360 yuan annually.

- Advantages of high-efficiency motors and variable frequency control: Permanent magnet motors utilize neodymium iron boron permanent magnets, offering high magnetic flux density and low losses. They maintain high efficiency even at low speeds (e.g., ≥92% efficiency at 1500 rpm). Variable frequency control supports 10%-100% load adjustment. When air demand drops to 50%, traditional models consume 70% of full-load energy, while permanent magnet models consume only 55% of full-load energy, further reducing part-load energy consumption.

High reliability and long service life

The structural design of permanent magnet screw compressors minimizes mechanical losses, enhancing equipment stability and service life:

- Minimal mechanical wear: Screw rotors feature high-precision machining and hardening treatment with precise clearance control, reducing meshing wear. Permanent magnet motors eliminate wear-prone components like brushes and slip rings, preventing failures caused by brush wear in traditional motors. Direct “motor-to-host” coupling eliminates belt slippage and coupling wear, extending core component lifespan to 8-10 years (compared to 5-6 years for conventional models).

- Low maintenance costs: Permanent magnet motors eliminate periodic carbon brush replacement, extending maintenance intervals to 6-12 months (vs. 3-6 months for conventional motors). Oil separator filter elements in oil-lubricated systems last up to 8,000 hours (vs. 6,000 hours for conventional models). Overall maintenance expenses are reduced by 20%-30% compared to conventional units, lowering enterprise operational expenditures.

Intelligent Control

Permanent magnet screw compressors are typically equipped with intelligent control systems to meet modern industrial automation requirements:

- PLC or Touchscreen Control Systems: Utilizing industrial-grade PLCs (Programmable Logic Controllers) paired with 7-10 inch color touchscreens, these systems provide intuitive displays of parameters including discharge pressure, temperature, flow rate, and motor speed. Supports one-touch start/stop and automatic loading/unloading, requiring no specialized skills and reducing labor costs;

- Remote Monitoring and Fault Diagnosis: Select models support 4G/5G or Ethernet remote connectivity, enabling users to monitor equipment status via mobile apps or computers (e.g., real-time energy consumption data and pressure curves); The system features self-diagnostic capabilities. When issues like low oil level, high temperature, or abnormal pressure occur, it automatically triggers alarms and displays fault codes, enabling maintenance personnel to quickly pinpoint problems and minimize downtime (average fault repair time reduced to 1-2 hours, compared to 3-4 hours for traditional models).

Environmental Protection & Low Noise

Amid rising global environmental awareness, the eco-friendly characteristics of permanent magnet screw compressors emerge as a key advantage:

- Energy Savings & Emissions Reduction: Low-energy design directly reduces electricity consumption and indirectly lowers CO₂ emissions from thermal power generation. For example, a 10m³/min model achieves annual energy savings of approximately (7.0-5.2) × 10 × 8 × 300 = 43,200 kWh, equivalent to reducing CO₂ emissions by about 32.4 tons (calculated at 0.75 kg CO₂ per kWh generated). Oil-free models prevent lubricant leakage that contaminates soil and water sources, complying with environmental regulations;

- Enhanced workplace comfort: Low-noise design (75-85dB) reduces noise levels by 5-10dB compared to conventional models (85-95dB), approaching typical office noise levels. Low-vibration characteristics minimize impact on workshop floors and equipment, prevent hearing damage from prolonged noise exposure, and improve workplace comfort and employee satisfaction.

Application Examples and Case Studies of Permanent Magnet Screw Compressors

Manufacturing Application Case

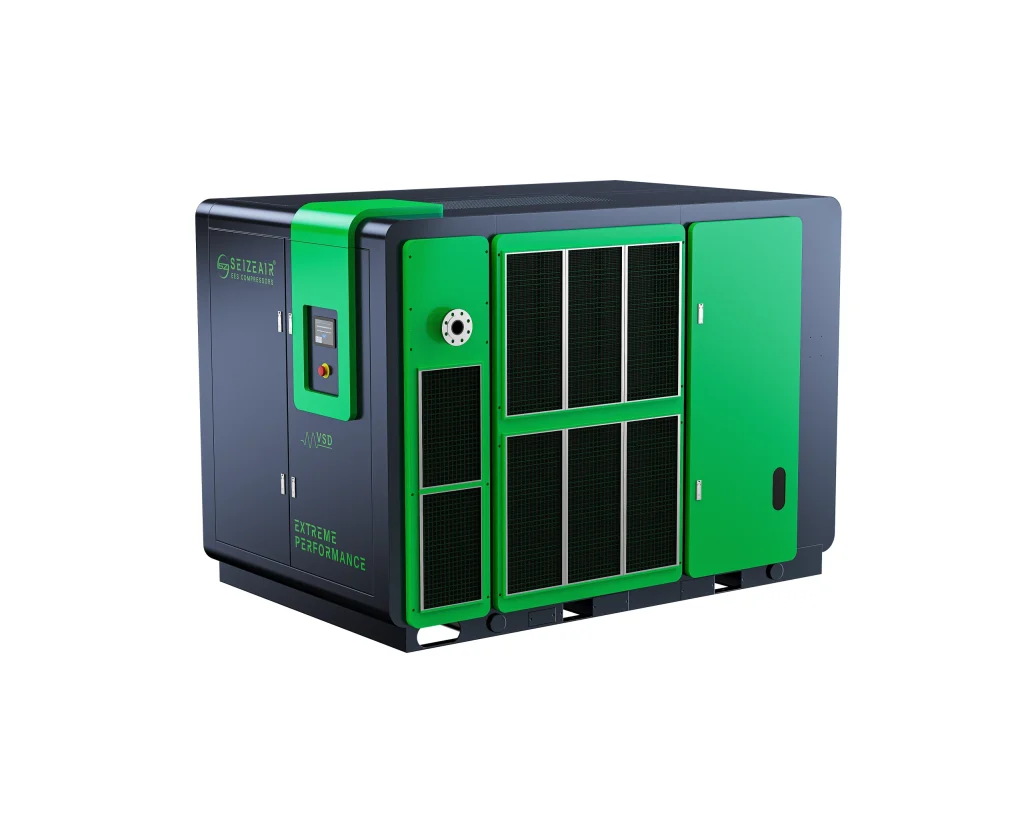

A global automotive parts manufacturer (China plant), specializing in engine valve production, required 24/7 compressed air supply (20m³/min flow rate, 0.8MPa pressure). Originally using four conventional variable-frequency screw compressors, annual electricity costs reached approximately 800,000 yuan. In 2023, the facility replaced these with two Seize brand permanent magnet screw compressors (model SM-20PM). Operational data revealed:

- Energy Savings: Overall specific power consumption reduced to 5.1 kW·h/m³, lowering annual electricity costs to ¥520,000—a savings of ¥280,000 per year. Payback period: approximately 1.5 years.

- Reliability: Equipment operated continuously for 12 months with zero unplanned shutdowns, pressure fluctuation ≤±0.01MPa, and valve machining precision pass rate increased by 1.2%;

- User Feedback: “The permanent magnet model operates stably. Maintenance frequency decreased from monthly to quarterly, reducing maintenance personnel workload by 60%. Workshop noise levels significantly decreased, leading to fewer employee complaints.”

Pharmaceutical Industry Oil-Free Permanent Magnet Screw Compressor Application Case

A European pharmaceutical company (Indian subsidiary) producing antibiotic drugs required GMP-compliant oil-free compressed air (oil content ≤0.01ppm, dew point ≤-40°C). Previously using dry oil-free piston compressors, they faced high energy consumption and unstable pressure. In 2022, the company introduced Seize oil-free permanent magnet screw compressors (Model SM-15PM-O):

- Compliance: Equipment certified to ISO 8573-1 Class 0 oil-free standards, meeting pharmaceutical production cleanliness requirements. No production batch issues caused by oil contamination have occurred.

- Energy Efficiency & Stability: Achieves 22% energy savings compared to traditional piston compressors, reducing annual electricity costs by ¥120,000; pressure fluctuations controlled within ±0.02MPa, preventing filling equipment shutdowns due to insufficient air pressure;

- User Feedback: “Remote monitoring enables real-time equipment status tracking without requiring on-site personnel. The oil-free design reduces consumable replacements in air treatment systems, lowering overall costs by 30%.”

Energy Industry Permanent Magnet Screw Compressor Application Case

A Middle Eastern oil and gas extraction company deployed pneumatic valve control equipment at oilfield wellheads, requiring compressed air to operate continuously under high temperatures (50°C) and dusty conditions (airflow 15m³/min, pressure 1.0MPa). Previously using conventional screw compressors, they experienced high failure rates (approximately 2 failures per month). In 2024, the company replaced the equipment with Seize high-temperature-resistant permanent magnet screw compressors (model SM-15PM-H):

- Reliability: With IP55 protection rating and optimized high-temperature adaptation, the compressors operated continuously for 6 months without failure, achieving 100% accuracy in wellhead valve control.

- Energy Savings: Achieved 18% energy savings compared to the previous model, reducing annual electricity costs for the oilfield by 90,000 yuan.

- User Feedback: “The permanent magnet model’s weather resistance and low energy consumption exceeded expectations, reducing field maintenance labor and proving suitable for harsh oilfield conditions.”

- Considerations for Selecting Permanent Magnet Screw Compressors

Permanent Magnet Screw Compressor Selection Guide

Selection must match actual gas demand to avoid “overkill” or “undersizing”:

- Flow Rate Matching: Calculate based on the total air consumption (m³/min) of all workshop equipment, reserving a 10%-20% margin (to accommodate new equipment or peak loads). For example, with a total consumption of 15m³/min, select a 18m³/min model.

- Pressure Matching: Select based on the maximum operating pressure of gas-consuming equipment to avoid overpressure operation (increasing energy consumption) or insufficient pressure (impeding production). Common industrial operating pressures range from 0.7-1.0MPa. If equipment requires 1.2MPa pressure, choose a corresponding high-pressure model.

- Power Matching: After determining flow and pressure, select high-efficiency models based on specific power consumption (kW·h/m³). Prioritize products with specific power ≤5.5 kW·h/m³ (meeting China’s National Class 1 Energy Efficiency Standard). Additionally, choose motors compatible with grid voltage (e.g., 380V/50Hz, 460V/60Hz) to prevent motor damage from voltage mismatch.

Permanent Magnet Screw Compressor Maintenance and Care Recommendations

Proper maintenance extends equipment lifespan and reduces failure risks:

- Regular Cleaning: Clean air filters every 1-2 months (monthly in dusty environments); replace immediately if clogged. Clean permanent magnet motor fins every 3 months to prevent dust buildup affecting heat dissipation.

- Oil Management (Oil-Lubricated Models): Change lubricating oil every 4,000-6,000 hours (depending on oil type). Regularly check oil level (maintain between upper and lower limits on dipstick) to prevent host wear from oil shortage. Replace oil-gas separator filter cartridge every 8,000 hours.

- Motor Maintenance: Prevent permanent magnet motors from operating under overload conditions (current must not exceed 110% of rated current). During extended shutdowns (over 1 month), manually rotate the motor weekly (3 revolutions per session) to prevent rotor corrosion.

- Environmental Control: Install equipment in a well-ventilated area with temperatures between 0-40°C, avoiding direct sunlight or rain exposure. Reserve at least 1.5 meters of maintenance space around the installation site for easy servicing.

Common Misconceptions When Purchasing Permanent Magnet Screw Compressors

Avoid procurement mistakes caused by cognitive biases:

- Misconception 1: Focusing solely on price while ignoring energy efficiency; Low-cost models may use inefficient permanent magnet motors or substandard screw rotors. While initial costs are low, long-term energy consumption is high, increasing total cost of ownership. Prioritize comparing specific power and energy efficiency certifications (e.g., National Class 1 Energy Efficiency, CE certification).

- Misconception 2: Neglecting after-sales service. Maintenance of permanent magnet screw compressors requires specialized technical expertise. If a brand has limited service centers or slow response times, downtime will increase during malfunctions. Verify the brand’s local service coverage during procurement (e.g., authorized service centers, spare parts inventory).

- Misconception 3: Ignoring operational environment suitability; High-temperature, high-humidity, or dusty environments (e.g., oil fields, mines) require models with high protection ratings (IP55 or higher) and heat resistance. Standard models may experience motor failures in such conditions.

- Misconception 4: Overemphasizing oil-free models; Oil-free models carry higher costs than oil-lubricated units. For applications without strict oil-free requirements (e.g., general machining), oil-lubricated models offer greater cost efficiency—provided oil-air separation efficiency (oil content ≤3ppm) is ensured.

Impact and Trends of Permanent Magnet Screw Compressors on Future Industrial Development

Driven by industrial automation and the “dual carbon” goals, permanent magnet screw compressors will evolve in three key directions:

- Higher Energy Efficiency: Adopting superior permanent magnet materials (e.g., samarium-cobalt magnets with enhanced high-temperature resistance) and optimized screw profiles (e.g., 6:7 profiles boosting compression efficiency by 5%) to further reduce specific power consumption.

- Smarter Integration: Integrating IoT technology to enable multi-unit cluster control, energy consumption data analysis, and predictive maintenance (using AI algorithms for early fault warnings);

- Specialized Application Adaptation: Developing dedicated models for extreme conditions (e.g., -30°C low temperatures, 1.5MPa high pressures) to meet demands in emerging sectors like new energy and aerospace.

Conclusion

For global industrial users prioritizing energy efficiency and reliability, permanent magnet screw compressors represent the optimal alternative to traditional models. Among brands, Seize air compressors stand out as a dependable choice due to their compliance with international certifications, high energy efficiency, and extensive after-sales coverage. Their low energy consumption, high stability, and eco-friendly characteristics not only help businesses reduce operational costs but also accelerate the global industrial transition toward greener, more efficient practices, providing core equipment-level support for sustainable development goals.