Introduction

Energy-efficient compressors play a vital role in modern industry. They not only provide a stable supply of compressed air for production but also help businesses achieve cost optimization and sustainable development goals by reducing energy consumption. With rising global energy prices and increasingly stringent environmental policies, high-efficiency energy-saving air compressors are becoming the preferred choice across industries. They help businesses maximize energy savings while enhancing production efficiency. This article comprehensively analyzes the core functions, application advantages, and industry best practices of high-efficiency energy-saving compressors, providing authoritative guidance for equipment selection and energy-saving decisions.

Core Concepts of High-Efficiency Energy-Saving Air Compressors

What is Energy Efficiency?

Energy efficiency refers to a device’s capability to perform work per unit of energy consumed. In air compressors, this directly relates to energy expenditure per cubic meter of compressed air. High-efficiency energy-saving compressors achieve lower energy consumption while delivering equivalent or even higher air volumes by optimizing motor efficiency, screw design, cooling systems, and control algorithms.

Differences Between Energy-Saving and Conventional Compressors

Conventional air compressors prioritize pressure and flow rate in design, often neglecting energy consumption control and system optimization. High-efficiency energy-saving compressors utilize advanced motors, variable frequency drives, and intelligent controls to achieve load matching, pressure regulation, and energy recovery. Compared to traditional equipment, they reduce energy consumption by 20%–40%, yielding significant cost savings for enterprises during long-term operation.

Potential Energy Savings and Return on Investment (ROI) of Energy-Efficient Compressors

The advantages of energy-efficient compressors extend beyond electricity consumption to include reduced maintenance costs and extended equipment lifespan. Industry experience indicates that businesses typically recoup their investment in high-efficiency compressors through energy savings within 1 to 3 years. Energy savings are particularly pronounced in high-consumption factories and continuous operation scenarios.

Top Energy-Saving Features Explained

Permanent Magnet Motors (PM Motors)

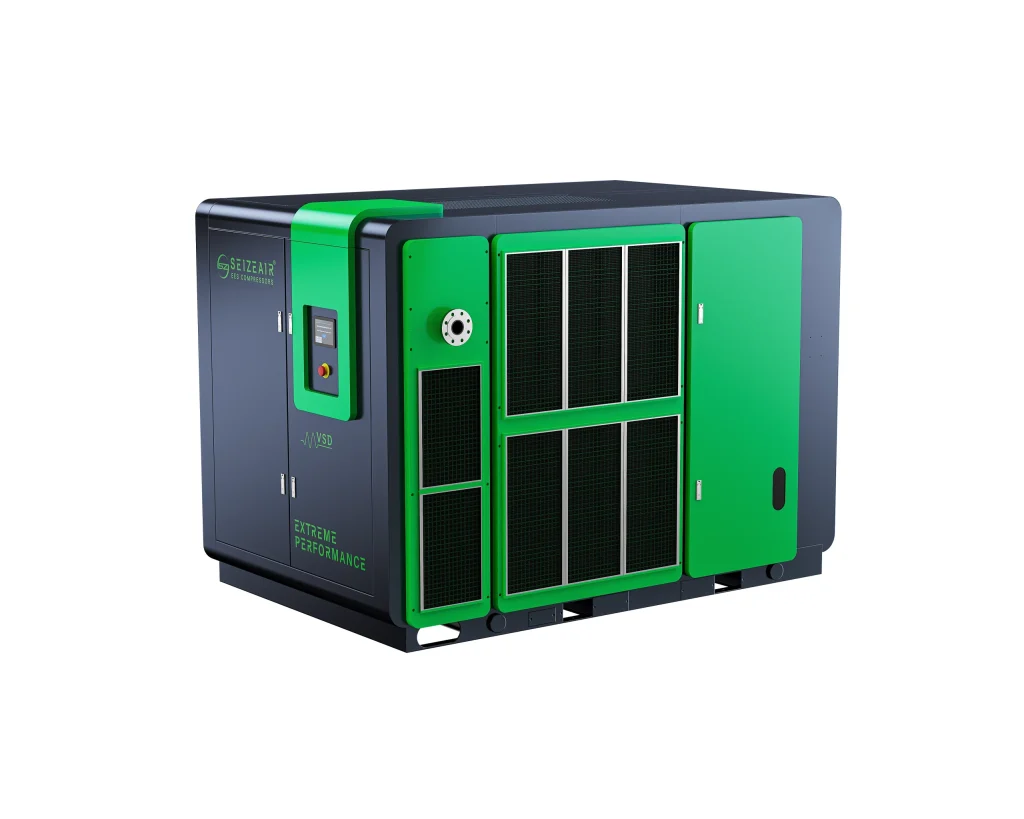

Permanent magnet motors serve as a core driving force for high-efficiency energy-saving air compressors. Compared to traditional asynchronous motors, PM motors directly drive the rotor using built-in high-performance magnets, minimizing internal energy losses and significantly boosting motor efficiency.

This design not only reduces electrical consumption but also decreases heat generation, alleviating cooling system loads and extending equipment lifespan. In industrial applications, permanent magnet motors maintain high efficiency output across varying loads, enabling substantial long-term electricity cost savings for enterprises. Particularly suited for continuous-duty production environments like food processing, automotive manufacturing, and pharmaceutical industries, these motors deliver stable pressure while significantly reducing energy consumption—an indispensable feature of energy-efficient compressors.

Variable Frequency Drive (VFD) Technology

Variable Frequency Drive technology is pivotal to modern high-efficiency compressor energy savings. By adjusting motor speed to match actual air demand, VFD technology eliminates the wasteful full-speed operation common in traditional compressors during low-load conditions.

VFD not only enhances compressor energy efficiency but also improves system operational stability and precision. In practice, businesses can achieve precise pressure control via VFD, preventing air leakage or oversupply to further reduce energy consumption.

Additionally, VFD compressors mitigate the impact of equipment starts and stops, extending mechanical lifespan and reducing maintenance costs. They serve as a common energy-saving solution in Industry 4.0 smart manufacturing and green factories.

Advanced Screw Compressor Design

The screw element is the core component of an air compressor, with its design directly impacting compression efficiency and energy consumption. Advanced screw designs utilize optimized tooth profiles, clearances, and materials to minimize internal friction losses and enhance compression efficiency.

By refining screw geometry, compressors deliver greater compressed air output at the same energy consumption, increasing air production per unit of energy. In industrial applications, this enables enterprises to meet peak load demands without increasing power consumption, maximizing energy utilization.

The high-efficiency screw design also integrates advanced lubrication and cooling systems to reduce wear and enhance equipment stability, ensuring long-term reliable operation for energy-efficient compressors.

Smart Control Systems

Smart control systems reduce energy consumption by continuously monitoring compressor operation and optimizing pressure, flow, and start/stop strategies. The system automatically adjusts output based on varying loads to achieve optimal energy-saving modes.

Additionally, these systems support remote monitoring and data analytics, helping businesses predict maintenance cycles, reduce failure rates, and increase equipment utilization. Globally, such systems have become essential tools for enhancing the return on investment in energy-efficient compressors.

Smart Control Systems can also integrate with factory Energy Management Systems (EMS) to optimize energy consumption across multiple devices, achieving greater energy savings at the enterprise level.

Enhanced Cooling Systems

Air compressors generate significant heat during operation. Enhanced cooling systems rapidly dissipate this heat, maintaining equipment within optimal temperature ranges. By optimizing cooling channel design and utilizing high-performance cooling media, these systems significantly reduce energy consumption increases caused by motor and screw overheating.

Beyond boosting compressor efficiency, these systems extend component lifespan and reduce maintenance frequency. For continuous-duty industrial environments like paper manufacturing, chemical processing, and mining, enhanced cooling ensures stable operation while lowering energy consumption, making it a crucial component of energy-efficient compressors.

Advantages of Energy-Efficient Compressors in Practical Applications

Energy Savings in Industrial Production

One of the greatest advantages of high-efficiency, energy-saving air compressors in industrial production is their significant reduction in energy consumption. Traditional compressors often waste energy during load fluctuations, whereas energy-efficient compressors equipped with permanent magnet motors, variable frequency drives, and intelligent control systems automatically adjust output flow and pressure based on actual demand.

In continuous factory environments, this dynamic regulation can boost energy utilization by 20% to 40%. For instance, in automotive manufacturing and electronics assembly, high-efficiency compressors deliver stable pressure during spraying, assembly, and testing processes while substantially reducing power consumption, yielding significant energy savings.

Reduced Operating and Maintenance Costs

High-efficiency compressors not only save electricity but also minimize maintenance costs by reducing mechanical wear and optimizing operational strategies. Advanced screw designs and efficient cooling systems minimize component friction and thermal stress, extending the lifespan of screws, motors, and bearings. Intelligent control systems provide early warnings of equipment anomalies, enabling scheduled maintenance to prevent production interruptions and energy waste. Over time, businesses not only reduce energy expenditures but also cut repair and spare parts costs, resulting in significantly lower overall operational expenses.

Enhancing Production Stability and Reliability

A stable air supply is a core requirement for modern industrial production. Energy-efficient air compressors achieve constant-pressure air supply through intelligent control and high-precision pressure regulation, ensuring production line equipment operates at optimal conditions at all times. Whether during high-load peaks or low-load fluctuations, energy-efficient compressors maintain stable performance, minimizing production interruptions or quality issues caused by pressure variations.

Supporting Corporate Sustainability Goals

As global industry transitions toward low-carbon and green production, energy-efficient air compressors provide essential tools for achieving sustainable development. By reducing energy consumption and carbon emissions, enterprises not only comply with environmental regulations but also enhance brand image and market competitiveness.

Long-Term Investment Return Advantages

The return on investment (ROI) for high-efficiency energy-saving compressors typically exceeds that of conventional models. Although initial equipment costs are slightly higher, enterprises can recoup investment within 1 to 3 years through electricity savings, reduced maintenance expenses, and minimized downtime losses.

Key Considerations When Selecting Energy-Efficient Air Compressors

Select Appropriate Models Based on Flow Requirements and Operating Conditions

When purchasing energy-efficient compressors, businesses should first determine the required compressed air flow and pressure based on actual production line needs. Compressor load fluctuations vary across different operating conditions; selecting equipment that is either oversized or undersized can lead to energy waste or failure to meet production demands.

Focus on Long-Term Operating Costs, Not Just Purchase Price

Although energy-efficient compressors involve slightly higher initial investment, their energy savings and reduced maintenance costs typically result in lower total long-term costs compared to conventional compressors. Businesses should comprehensively evaluate equipment lifespan, energy consumption metrics, maintenance frequency, and potential failure rates, prioritizing Total Cost of Ownership (TCO) as the core reference.

Verify Manufacturer-Provided Energy Efficiency Certifications and Technical Specifications

Verify the equipment’s energy efficiency rating, performance curves, and certification data during selection to ensure reliable energy-saving metrics and mitigate investment risks.

The Importance of After-Sales Service and Maintenance Support

Comprehensive after-sales service, technical support, and remote monitoring systems ensure the long-term stable operation of high-efficiency energy-saving compressors, extending equipment lifespan and maintaining energy-saving performance.

Consider Installation Environment and System Compatibility

Proper ventilation, suitable temperatures, rational piping design, and compatible air storage systems maximize compressor efficiency and prevent energy waste.

Industry Application Cases and Best Practices

Energy Conservation Practices in Automotive Manufacturing

During painting, welding, and assembly processes, energy-efficient compressors achieve precise air pressure matching through variable frequency control, reducing power consumption while enhancing production continuity.

Energy Applications in Food and Beverage Industry

High-efficiency compressors maintain constant pressure supply during bottling and packaging operations. They automatically reduce speed during low-load periods, minimizing energy consumption while ensuring stable equipment operation.

High-Efficiency Compressor Applications in Chemical and Pharmaceutical Industries

Intelligent control systems enable adaptive load regulation, lowering energy consumption while ensuring production compliance with GMP standards, thereby enhancing product quality and equipment reliability.

Other Typical Industrial Cases

Mining, paper, and textile industries achieved 20%–40% energy savings after adopting high-efficiency compressors, while also extending equipment lifespan and improving maintenance efficiency.

Case Study Summary

Across diverse industrial scenarios, energy-efficient compressors integrated with intelligent control and load-matching technologies maximize energy savings and return on investment.

Maintenance and Management Recommendations for Energy-Efficient Compressors

Importance of Regular Inspection and Maintenance

Periodic maintenance of screws, motors, and control systems—along with filter cleaning and lubricant quality checks—ensures sustained high-efficiency operation and extended equipment lifespan.

Role of Intelligent Monitoring Systems in Maintenance Management

Collecting operational data via sensors and remote monitoring enables timely detection of potential faults, optimization of energy-saving modes, and maximization of energy management.

Proactive Fault Prevention for Enhanced Efficiency and Equipment Lifespan

Implementing predictive maintenance based on operational data prevents failures, ensuring long-term high-efficiency compressor operation.

Management Strategies and Operator Training

Standardizing operations and training personnel in proper compressor usage—avoiding full-load operation during low-demand periods—further optimizes energy utilization efficiency.

Future Development Trends

Integration of New Energy-Saving Technologies and Green Energy

Future high-efficiency compressors will integrate renewable energy sources for low-carbon operation while adopting advanced materials and efficient lubrication technologies to further enhance energy efficiency.

Application of IoT and Industry 4.0 in Energy Conservation

IoT and Industry 4.0 technologies enable real-time monitoring, data analysis, and predictive maintenance, dynamically adjusting compressor operating modes to improve overall energy savings.

Industry Development Direction for High-Efficiency Compressors

With increasing global demand for low-carbon production, enterprises will prioritize compressors offering comprehensive performance in energy efficiency, reliability, intelligence, and low-noise environmental protection.

Competitive Advantages from Technological Innovation

Companies mastering advanced energy-saving compressor technologies can reduce costs, enhance production efficiency and product quality, comply with global environmental regulations, and strengthen market competitiveness.

Conclusion

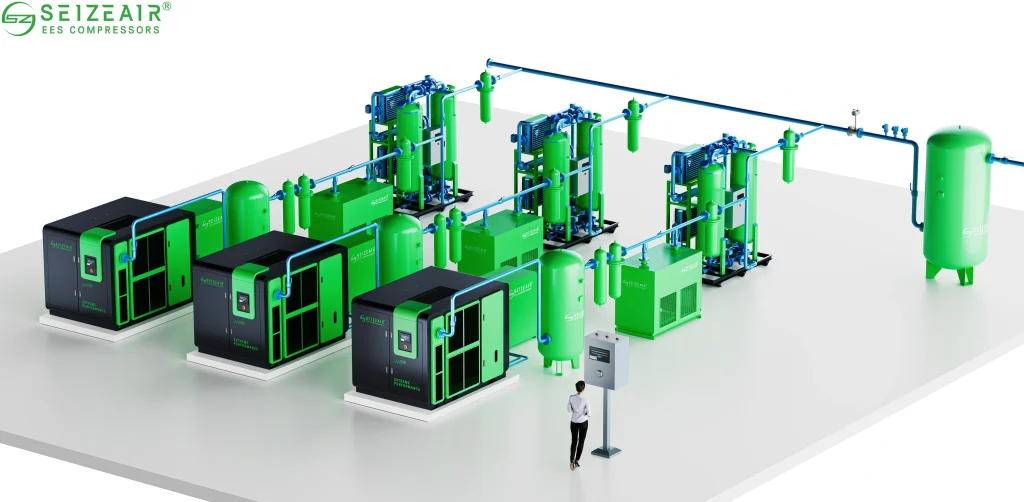

High-efficiency energy-saving air compressors play an irreplaceable role in global industry, significantly reducing energy consumption and operational costs while improving production stability and equipment lifespan. When selecting energy-efficient compressors, enterprises should prioritize flow matching, variable frequency control, intelligent management, and maintenance strategies to maximize energy savings. As an industry-leading brand, Seize offers multiple high-efficiency models integrating permanent magnet motors, smart controls, and optimized screw designs. We deliver reliable, energy-saving, and high-performance compressed air solutions to global customers, empowering businesses to achieve low-carbon production and long-term investment returns.