Introduction

Air Compressors: The Foundational Power Source for Industrial Production

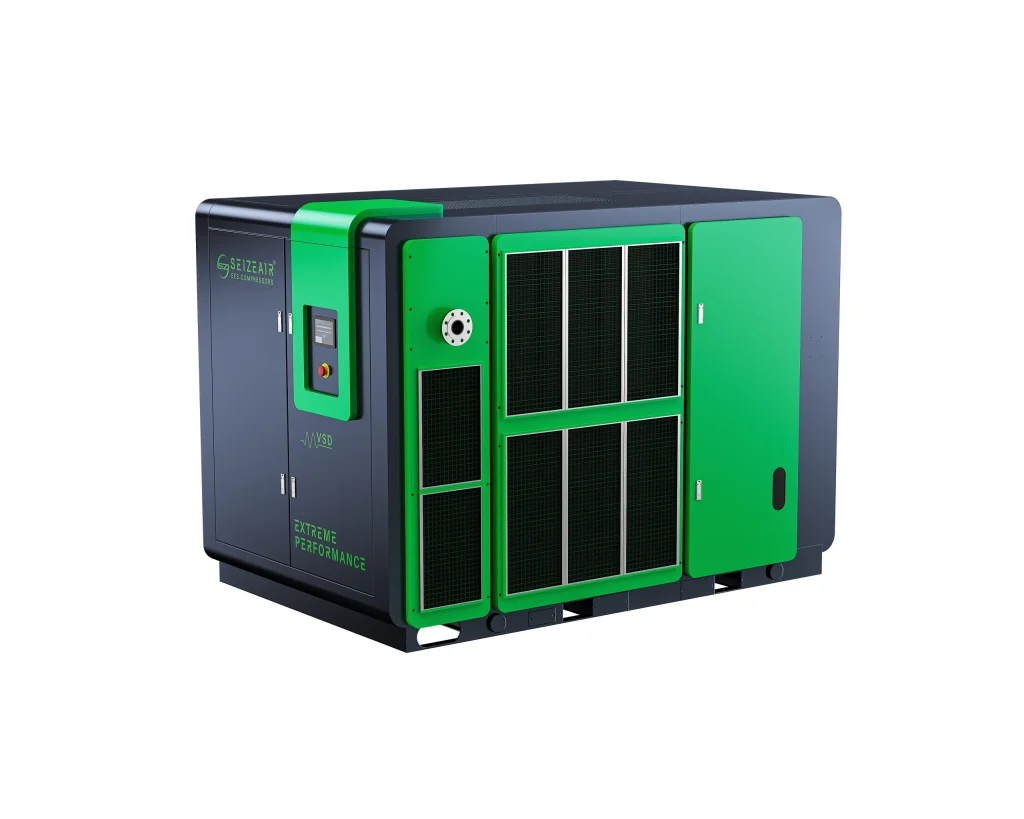

In modern industry, air compressors serve as core power equipment across sectors including food and beverage, textiles, chemicals, and electronics manufacturing. Scenarios such as pneumatic-driven food packaging machinery, air-jet yarn-guiding in textile looms, and aeration-stirring in chemical reactors all require stable compressed air support. Approximately 10%-15% of industrial electricity consumption is dedicated to compressed air production. Operational efficiency directly impacts corporate costs and production stability, making the selection of high-efficiency, reliable air compressors crucial for cost reduction and productivity enhancement.

Core Value and Application Scenarios of Two-Stage Screw Compressors

Compared to single-stage screw compressors, Two-Stage Screw Compressors achieve greater energy efficiency, stability, and extended lifespan in high-pressure, high-flow applications through their “two-stage compression + intermediate cooling” design. They are now widely adopted in high-pressure pure gas supply scenarios—such as sterile food packaging, high-pressure dust removal in electronics, and high-pressure material transfer in chemical plants—serving as essential equipment for green manufacturing.

What is Two Stage Screw Compressors

Definition of Two-Stage Screw Compressors

A two-stage screw compressor is a positive displacement compression device that sequentially compresses air through two independent compression chambers (primary and secondary). An intercooler positioned between the stages reduces the temperature of gas after the first compression stage, minimizing energy consumption and equipment temperature rise. This ultimately achieves efficient and stable high-pressure air supply output.

Primary Components of a Two-Stage Screw Air Compressor

- Rotors: The rotors form the core of the compression chamber. Consisting of a male rotor (active) and a female rotor (passive), they achieve gas sealing and compression through precise meshing. In two-stage models, the rotors differ in size: the primary rotor features larger tooth-tooth volumes for high-volume intake, while the secondary rotor has smaller volumes for high-pressure compression. Manufactured from high-strength alloy steel, rotor clearances are controlled between 0.01-0.03mm to minimize gas leakage.

- Casing: The casing, made of cast iron or cast steel, encloses the rotors to form a sealed compression chamber while supporting components and aiding heat dissipation. Internal walls feature channels designed along the airflow path to guide air entry and exit. An interface for an intercooler is reserved between the two compression chambers, ensuring high-temperature gas smoothly enters the cooling stage.

- Lubrication System: The lubrication system comprises an oil tank, oil pump, oil filter, and oil cooler. Its functions include: lubricating rotors and bearings to reduce friction; filling rotor clearances to enhance sealing; and absorbing compression heat to assist cooling. For two-stage operation, a “graded oil supply” design is employed, matching oil volume and pressure to each compression stage for optimal lubrication.

- Inlet and Outlet Valves: The inlet valve comprises primary and secondary stages: the primary valve connects to the air filter, automatically adjusting its opening based on system pressure to regulate air intake; the secondary valve connects to the intercooler, ensuring smooth gas entry into the secondary compression chamber. The outlet valve employs a one-way valve structure to prevent high-pressure gas backflow, guaranteeing stable output pressure.

Core Differences from Single-Stage Screw Air Compressors

- Differences in Compression Efficiency, Temperature Rise, and Energy Consumption: Single-stage models feature only one compression chamber. To achieve target pressures (e.g., 0.8MPa), they endure a high compression ratio of 6-8, causing gas temperatures to rise to 160-180°C. This accelerates lubricant degradation, increases motor energy consumption, and results in specific power consumption of 7.5-8.5kW/(m³/min). Two-stage models distribute the compression ratio across two stages: primary stage with a 3-5 compression ratio, pressure of 0.3-0.5MPa, and temperature of 120-150°C. After cooling to 40-50°C, the secondary stage applies a 2-4 compression ratio to achieve the final pressure, with discharge temperatures of 100-130°C. The specific power consumption of two-stage models drops to 6.0-7.0 kW/(m³/min), achieving 15%-25% energy savings under identical operating conditions with smoother temperature rise.

Primary Industries for Two-Stage Screw Air Compressors

- Food & Beverage Industry: Used in aseptic packaging, dairy product conveyance, and beer CO₂ recovery. Treated output air contains less than 0.01mg/m³ oil content, preventing raw material contamination. Stable pressure ensures packaging seal integrity and boosts yield rates.

- Textile Industry: Meets high-pressure airflow demands for air-jet and water-jet looms. Pressure fluctuations controlled within ±0.02MPa minimize water separation, prevent yarn breakage, and boost weaving efficiency.

- Chemical Industry: Supports high-pressure material transfer and reactor aeration. Delivers 1.2-1.6MPa high-pressure gas with robust load fluctuation resistance, aligning with energy-saving and carbon reduction requirements.

- Electronics Manufacturing Industry: When paired with precision filters, the air source achieves dust particle size ≤0.1μm and oil content ≤0.001mg/m³, suitable for chip dust removal and wafer cleaning. Operating noise ≤75dB meets electronics factory environmental requirements.

- Other High-Pressure Gas Applications: Also deployed in mining pneumatic rock drills, ship deck machinery, and medical autoclaves. Its high-pressure output and extended lifespan enhance operational efficiency and safety.

Working Principle of Two-Stage Screw Compressors

Air Intake Stage

The two-stage air intake process operates in two distinct phases: Atmospheric air first passes through an air filter to intercept dust and impurities before entering the primary intake valve. The control system adjusts the primary intake valve opening based on air receiver pressure: fully open at low pressure and partially close when pressure is sufficient to prevent inefficient energy consumption. The secondary intake draws cooled gas from the first-stage compression. This gas enters the secondary compression chamber at a uniform velocity via the secondary intake valve, laying the foundation for high-pressure compression.

Low Stage Compression

After clean air enters the primary compression chamber, the motor drives the primary male rotor to rotate, driving the female rotor to mesh and rotate. Rotor rotation reduces the inter-tooth volume, compressing the air to achieve initial pressure increase. Pressure rises from 0.1 MPa to 0.3-0.5 MPa, with temperature simultaneously increasing to 120-150°C. The lubrication system injects oil into the primary compression chamber to reduce friction, absorb heat, and prevent localized overheating. When the inter-tooth volume reaches its minimum, primary compression is complete, and the high-temperature, high-pressure gas enters the intermediate cooling stage.

Intercooling

Intercooling is central to energy efficiency and stable operation, serving to reduce gas temperature after primary compression and minimize secondary energy consumption and equipment load. Mainstream equipment employs shell-and-tube (water-cooled heat exchange) or air-cooled (fan-dissipated) coolers. High-temperature gas at 120-150°C is cooled to 40-50°C. During cooling, water vapor in the gas condenses into liquid water. This water is expelled via a drain valve, preventing its entry into the secondary compression chamber where it could impair efficiency or cause corrosion. This process reduces secondary compression energy consumption by over 30%.

High Stage Compression

The cooled gas (0.3-0.5MPa, 40-50°C) enters the secondary compression chamber through the secondary inlet valve, initiating the high-stage compression process. The meshing secondary rotors reduce the inter-tooth volume. Since the gas is pre-compressed, only a 2-4 compression ratio is required to elevate pressure to 0.7-1.6MPa (custom models can exceed 3.0MPa). The lubrication system injects oil into the secondary compression chamber to ensure lubrication and sealing. The temperature increase during secondary compression is minimal, with final discharge temperature controlled between 100-130°C to prevent equipment damage. When the inter-tooth volume reaches its minimum, the high-pressure gas is discharged and enters the oil-gas separation and purification stage.

Exhaust and Control System

After exiting the secondary compression chamber, high-pressure gas first enters the oil-gas separator. Centrifugal force and filtration remove lubricating oil (reducing oil content to below 0.1mg/m³), with separated oil recirculating to the tank for reuse. Purified gas is conveyed via the exhaust valve to the air receiver or end-use equipment, supplying energy for production. The control system, centered on pressure and temperature sensors, continuously monitors conditions: opening the primary inlet valve when pressure is low, closing it or relieving pressure when high, and triggering alarms while enhancing cooling when temperatures exceed limits—ensuring safe operation.

Two-Stage Screw Compressor Operational Steps

- Primary Intake: Filtered atmospheric air enters the primary compression chamber via the primary intake valve.

- Primary Compression: The primary rotor reduces the inter-tooth volume, compressing gas to 3-5 bar pressure and 80-100°C temperature.

- Intermediate Cooling: High-temperature gas is cooled to 40-50°C, causing moisture to condense and drain.

- Secondary Intake: Cooled gas enters the secondary compression chamber via the secondary intake valve.

- Secondary Compression: The secondary rotor reduces volume, achieving gas pressure of 8-13 bar and temperature of 90-110°C.

- Discharge and Purification: High-pressure gas exits through the discharge valve, undergoes aftercooling and oil-gas separation before delivery to the application point.

Key Advantages of Two-Stage Screw Compressors

High Efficiency & Energy Savings: Reduces operating costs while aligning with environmental sustainability trends. Two-stage designs distribute compression work and reduce secondary energy consumption through intercooling.

Extended Equipment Lifespan: Low temperature rise and reduced load increase longevity; bearing lifespan reaches 80,000-100,000 hours.

Stable and Pure Air Supply: Pressure fluctuation ≤±0.2 bar; oil content ≤0.01 mg/m³; suitable for precision industries.

Adaptable to High-Pressure and High-Flow Demands: Delivers stable 10-20 bar air; custom models up to 30 bar; supports parallel operations.

Low Maintenance Costs: 20%-30% lower; modular design; quick filter replacement; comprehensive fault warning system.

Two Stage Screw Compressor Usage and Selection Recommendations

- Required Pressure (bar/PSI): Determine equipment pressure and add 0.5-1 bar margin.

- Required Flow Rate (CFM/m³/min): Total flow = sum of equipment flow ×1.2 +10%-15% for expansion.

- Energy Efficiency Ratio (Specific Power): Lower kW/(m³/min) = higher efficiency. Variable-frequency models for fluctuating loads; fixed-frequency for stable loads.

- Factory Load Requirements: Consider voltage, space, and environment. Corrosion/dust protection as needed.

Installation and Operation Precautions

- Ensure ventilation, heat dissipation, and avoid hot air recirculation.

- Select proper lubricants.

- Regular maintenance: clean filters, replace oil and filter elements on schedule.

Common Issues and Solutions

Noise and Vibration: Check foundation, rotor balance, bearings, pipe installation.

Reduced Compression Efficiency: Inspect filters, valves, rotor clearance, intercooler, and separators.

Overheating/Insufficient Lubrication: Check oil level, cooler, oil quality, fans, and ambient temperature.

Unstable or Fluctuating Pressure: Inspect sensors, valves, pipelines, and load conditions.

Conclusion

Two-Stage Screw Compressor Core Value:

- Energy Efficiency: 15%-25% more than single-stage.

- Extended Lifespan: Low temperature rise, low load.

- Premium Air Quality: Stable, high-purity pressure.

- Versatile Applications: 8-20 bar output.

Recommendations: Precise selection, proper installation, regular maintenance.

Contact Seize for purchasing, free selection quotes, or troubleshooting guidance. Selecting the right compressor reduces costs and enhances production stability.